- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 20, 2025 09:54

Back to list

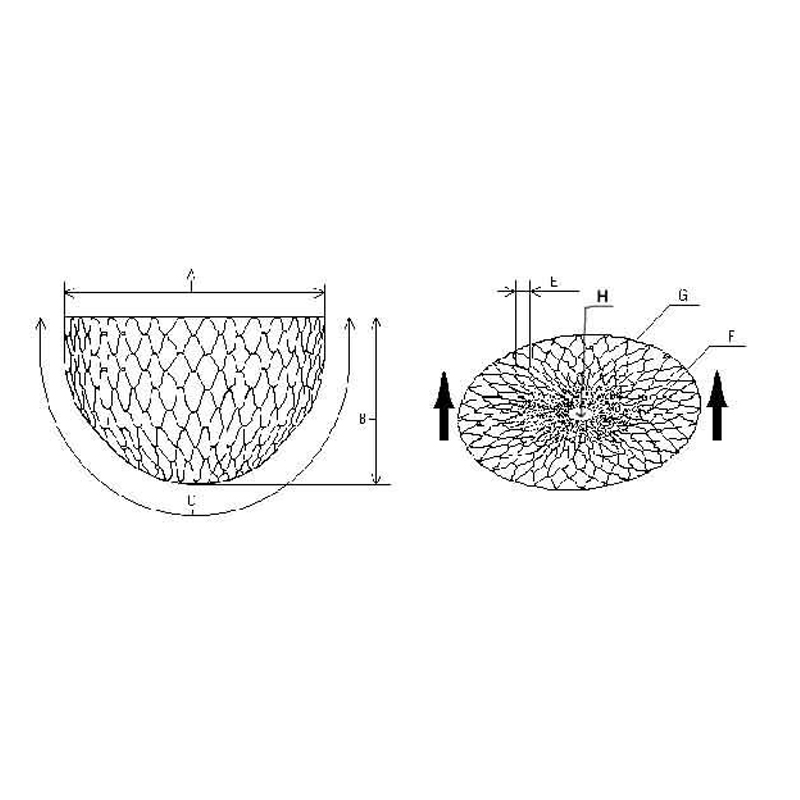

Concrete reinforcement wire mesh

Concrete reinforcing mesh has become an indispensable component in modern construction, offering both strength and flexibility to structures while ensuring longevity. Its unique grid-like pattern is vital for distributing loads evenly across concrete surfaces, preventing cracking, and providing an added measure of safety to various construction projects.

Construction engineers frequently choose concrete reinforcing mesh for its economic benefits as well. By using this mesh, the need for excessive concrete pour is minimized, resulting in significant cost savings on materials. Additionally, the quick and easy installation process reduces labor costs and accelerates project timelines. This financial prudence does not come at the cost of quality, as the mesh ensures that both the budgetary and structural requirements of a project are efficiently met. Concrete reinforcing mesh is lauded for its sustainability. As the world moves towards greener construction practices, the mesh stands out as an environmentally friendly choice. Its production process consumes less energy compared to other reinforcing methods, and the steel used is often recyclable. By choosing concrete reinforcing mesh, construction firms not only commit to building robust structures but also contribute to a more sustainable future. Safety remains a paramount concern in construction, and concrete reinforcing mesh is pivotal in addressing this issue. Its implementation within projects enhances structural stability and minimizes the risk of catastrophic failures. Safety inspectors and structural engineers consistently highlight the importance of this mesh in maintaining high safety standards across construction sites. In conclusion, the implementation of concrete reinforcing mesh within the construction industry aligns with both traditional building practices and modern advancements. Its unparalleled strength, versatility, and sustainability position it as a cornerstone of contemporary construction efforts. For builders, architects, and engineers seeking to optimize their projects both in terms of performance and cost, concrete reinforcing mesh is an essential element, facilitating the creation of secure and enduring infrastructures. This convergence of durability, economic efficiency, and environmental responsibility underscores why concrete reinforcing mesh is indispensable in crafting the resilient structures of tomorrow.

Construction engineers frequently choose concrete reinforcing mesh for its economic benefits as well. By using this mesh, the need for excessive concrete pour is minimized, resulting in significant cost savings on materials. Additionally, the quick and easy installation process reduces labor costs and accelerates project timelines. This financial prudence does not come at the cost of quality, as the mesh ensures that both the budgetary and structural requirements of a project are efficiently met. Concrete reinforcing mesh is lauded for its sustainability. As the world moves towards greener construction practices, the mesh stands out as an environmentally friendly choice. Its production process consumes less energy compared to other reinforcing methods, and the steel used is often recyclable. By choosing concrete reinforcing mesh, construction firms not only commit to building robust structures but also contribute to a more sustainable future. Safety remains a paramount concern in construction, and concrete reinforcing mesh is pivotal in addressing this issue. Its implementation within projects enhances structural stability and minimizes the risk of catastrophic failures. Safety inspectors and structural engineers consistently highlight the importance of this mesh in maintaining high safety standards across construction sites. In conclusion, the implementation of concrete reinforcing mesh within the construction industry aligns with both traditional building practices and modern advancements. Its unparalleled strength, versatility, and sustainability position it as a cornerstone of contemporary construction efforts. For builders, architects, and engineers seeking to optimize their projects both in terms of performance and cost, concrete reinforcing mesh is an essential element, facilitating the creation of secure and enduring infrastructures. This convergence of durability, economic efficiency, and environmental responsibility underscores why concrete reinforcing mesh is indispensable in crafting the resilient structures of tomorrow.

share:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025