- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

feb . 14, 2025 13:21

Back to list

stucco wire mesh for sale

Wire mesh for stucco is an essential component in creating durable and aesthetically pleasing stucco finishes on various architectural structures. When considering this crucial product, understanding its benefits, applications, and installation techniques can significantly enhance the overall quality and longevity of the stucco application. As an industry expert, I am dedicated to sharing my professional insights into the world of wire mesh for stucco, establishing a comprehensive view that addresses its importance with unrivaled authority and trustworthiness.

Another layer of trustworthiness is added when considering compliance with local building regulations and standards, which necessitates awareness of wire gauge, mesh size, and fastening methods specified by the building code. Trusted sources, including the Portland Cement Association and ASTM International, provide guidelines that professionals should adhere to for optimal performance. In recent years, the innovation in materials and manufacturing have also allowed for newer wire mesh products that promise easier handling, quicker installation, and environmentally friendly components. For instance, advanced versions of the stucco mesh are designed to be lighter while maintaining robustness, allowing for less labor-intensive installation processes. Furthermore, some manufacturers have developed eco-friendly variants using recycled materials without compromising on quality, thus appealing to environmentally-conscious builders. Ultimately, choosing wire mesh for stucco becomes a seamless decision when armed with the right expertise and authoritative knowledge. Sourcing wire mesh from reputable suppliers, who guarantee quality and consistency, forms the backbone of a sound investment in building longevity. By combining effective product selection with meticulous installation practices, the stucco application is set up for resilience against environmental stresses and the passage of time. In conclusion, wire mesh for stucco is more than just a supportive reinforcement; it underscores the importance of expertise and meticulous craftsmanship in architectural projects. This discourse integrates experience, technical skill, and authoritative guidance to equip builders, designers, and homeowners with a superior understanding of stucco wire mesh applications. Ultimately, ensuring that every stucco application not only meets but exceeds durability and aesthetic expectations is within reach by recognizing the critical role of wire mesh in stucco systems.

Another layer of trustworthiness is added when considering compliance with local building regulations and standards, which necessitates awareness of wire gauge, mesh size, and fastening methods specified by the building code. Trusted sources, including the Portland Cement Association and ASTM International, provide guidelines that professionals should adhere to for optimal performance. In recent years, the innovation in materials and manufacturing have also allowed for newer wire mesh products that promise easier handling, quicker installation, and environmentally friendly components. For instance, advanced versions of the stucco mesh are designed to be lighter while maintaining robustness, allowing for less labor-intensive installation processes. Furthermore, some manufacturers have developed eco-friendly variants using recycled materials without compromising on quality, thus appealing to environmentally-conscious builders. Ultimately, choosing wire mesh for stucco becomes a seamless decision when armed with the right expertise and authoritative knowledge. Sourcing wire mesh from reputable suppliers, who guarantee quality and consistency, forms the backbone of a sound investment in building longevity. By combining effective product selection with meticulous installation practices, the stucco application is set up for resilience against environmental stresses and the passage of time. In conclusion, wire mesh for stucco is more than just a supportive reinforcement; it underscores the importance of expertise and meticulous craftsmanship in architectural projects. This discourse integrates experience, technical skill, and authoritative guidance to equip builders, designers, and homeowners with a superior understanding of stucco wire mesh applications. Ultimately, ensuring that every stucco application not only meets but exceeds durability and aesthetic expectations is within reach by recognizing the critical role of wire mesh in stucco systems.

share:

Next:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

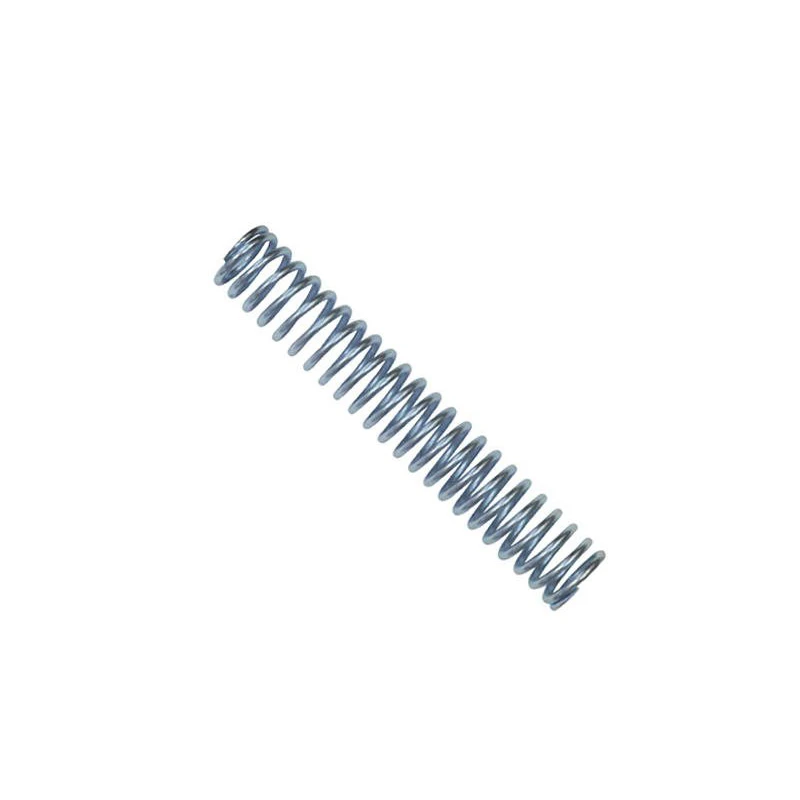

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

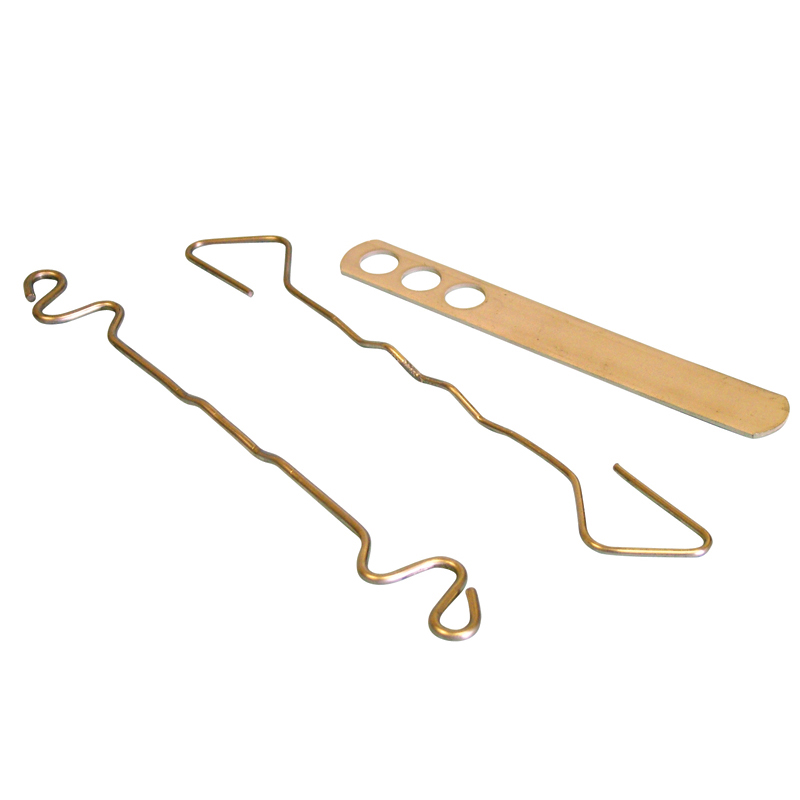

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025