- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

feb . 11, 2025 17:59

Back to list

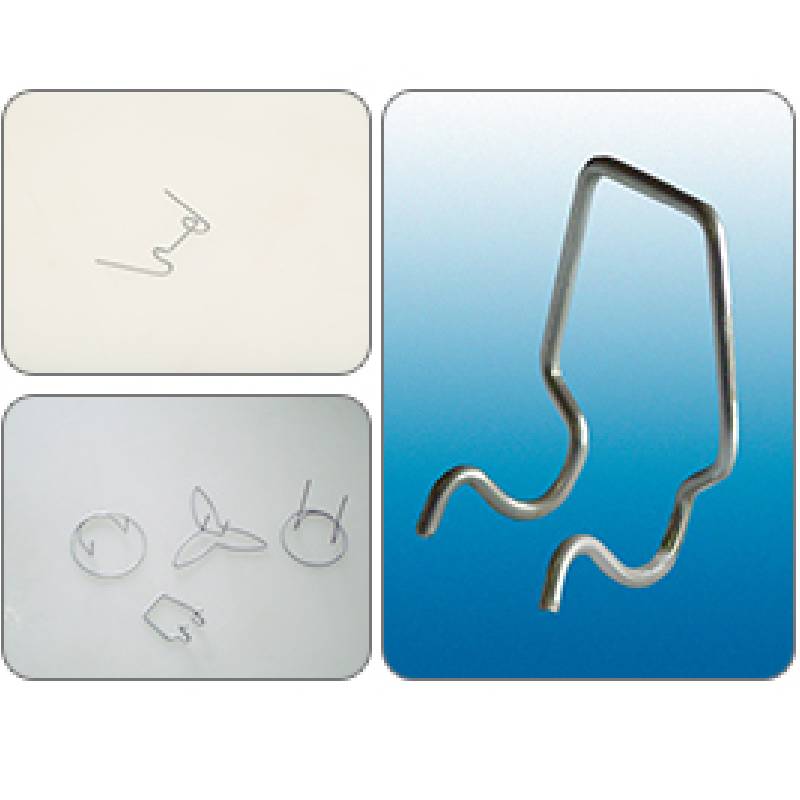

welded wire grid

Welded wire grid, an essential component in both industrial and consumer applications, stands at the intersection of engineering ingenuity and material science innovation. As a critical tool in the construction and manufacturing industries, the welded wire grid has proven to be indispensable due to its strength, versatility, and adaptability. Understanding the unique capabilities of this material is essential for industries looking to optimize safety, efficiency, and cost-effectiveness in their operations.

Authoritativeness in the field of welded wire grids comes from the extensive research and development invested in optimizing this product's performance. Industry standards and certifications play a pivotal role in ensuring that these grids meet stringent safety guidelines. Manufacturers invest heavily in quality control processes to produce grids that consistently exceed industry requirements. They often work alongside construction and engineering firms to validate performance through real-world testing scenarios, further reinforcing the product's reputation. A real-life example underscores the impact of welded wire grids’ role in infrastructural evolution. In the renovation of historical bridges, engineers have turned to welded wire grids for reinforcement, seamlessly combining modern engineering principles with heritage conservation. The adaptability of welded wire grids allows for enhancements without altering the bridge's original design, maintaining aesthetic appeal while ensuring enhanced structural security. From an environmental perspective, welded wire grids contribute to sustainable construction practices. Steel, being highly recyclable, allows grids to align with modern eco-friendly initiatives. The production process itself has also become more energy-efficient over time, reducing the carbon footprint associated with construction activities. By incorporating recycled materials and reducing waste, the welded wire grid aligns with global efforts to prioritize environmental responsibility. In summary, the welded wire grid is a testament to engineering innovation, bringing together strength, adaptability, and efficiency. Its applications are as diverse as they are essential—from construction and agriculture to safety and security. By adhering to high industry standards and continuously adapting to the demands of evolving technologies, manufacturers uphold the welded wire grid's reputation as a reliable and trustworthy choice. As demands for advanced construction materials increase, the relevance of welded wire grids will continue to expand, supporting developments in infrastructure and industry for years to come.

Authoritativeness in the field of welded wire grids comes from the extensive research and development invested in optimizing this product's performance. Industry standards and certifications play a pivotal role in ensuring that these grids meet stringent safety guidelines. Manufacturers invest heavily in quality control processes to produce grids that consistently exceed industry requirements. They often work alongside construction and engineering firms to validate performance through real-world testing scenarios, further reinforcing the product's reputation. A real-life example underscores the impact of welded wire grids’ role in infrastructural evolution. In the renovation of historical bridges, engineers have turned to welded wire grids for reinforcement, seamlessly combining modern engineering principles with heritage conservation. The adaptability of welded wire grids allows for enhancements without altering the bridge's original design, maintaining aesthetic appeal while ensuring enhanced structural security. From an environmental perspective, welded wire grids contribute to sustainable construction practices. Steel, being highly recyclable, allows grids to align with modern eco-friendly initiatives. The production process itself has also become more energy-efficient over time, reducing the carbon footprint associated with construction activities. By incorporating recycled materials and reducing waste, the welded wire grid aligns with global efforts to prioritize environmental responsibility. In summary, the welded wire grid is a testament to engineering innovation, bringing together strength, adaptability, and efficiency. Its applications are as diverse as they are essential—from construction and agriculture to safety and security. By adhering to high industry standards and continuously adapting to the demands of evolving technologies, manufacturers uphold the welded wire grid's reputation as a reliable and trustworthy choice. As demands for advanced construction materials increase, the relevance of welded wire grids will continue to expand, supporting developments in infrastructure and industry for years to come.

share:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025