- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

feb . 16, 2025 09:56

Back to list

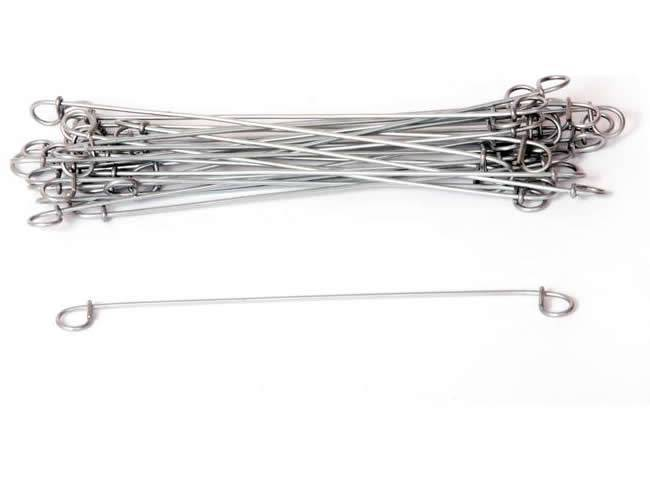

plastering metal corner bead

Stainless steel render beads have become an essential component in modern construction and renovation projects, providing both aesthetic appeal and functional benefits. With years of experience in the construction industry, I've come to appreciate the nuanced choices that can make a significant difference in project outcomes. As an expert in the field, I can affirm that understanding product features and proper application techniques ensures superior results.

Regarding the authority surrounding the selection and use of stainless steel render beads, consulting industry standards and guidelines is paramount. The British Standards Institution (BSI) provides specific codes that outline the correct selection and application of these products to guarantee they meet safety and performance criteria. Familiarity with such standards ensures that installations not only meet legal requirements but also perform reliably over time. Trustworthiness in product selection often relies on transparency in manufacturing processes and material sourcing. It is critical to source stainless steel render beads from reputable suppliers who provide detailed product specifications, including the grade of stainless steel used and its compliance with industry standards. This transparency ensures that installers and clients alike can place their trust in the longevity and performance of the product. Innovative technologies and manufacturing advancements have further enhanced the reliability and performance of stainless steel render beads. Many manufacturers now offer enhanced features such as integrated mesh for added bonding strength or specialized coatings to improve adhesion with specific types of plaster. Staying abreast of these innovations allows professionals to leverage cutting-edge solutions that offer improved durability and performance. In conclusion, stainless steel render beads are more than just a construction accessory; they are a critical component affecting both the aesthetics and durability of plastered surfaces. With a keen understanding of the product's technical benefits regarding strength and longevity, adherence to best practice installation techniques, and compliance with authoritative standards, professionals can ensure that these beads fulfill their potential. Relying on trustworthy suppliers further ensures that the products used will stand the test of time, ultimately resulting in successful and aesthetically pleasing construction projects.

Regarding the authority surrounding the selection and use of stainless steel render beads, consulting industry standards and guidelines is paramount. The British Standards Institution (BSI) provides specific codes that outline the correct selection and application of these products to guarantee they meet safety and performance criteria. Familiarity with such standards ensures that installations not only meet legal requirements but also perform reliably over time. Trustworthiness in product selection often relies on transparency in manufacturing processes and material sourcing. It is critical to source stainless steel render beads from reputable suppliers who provide detailed product specifications, including the grade of stainless steel used and its compliance with industry standards. This transparency ensures that installers and clients alike can place their trust in the longevity and performance of the product. Innovative technologies and manufacturing advancements have further enhanced the reliability and performance of stainless steel render beads. Many manufacturers now offer enhanced features such as integrated mesh for added bonding strength or specialized coatings to improve adhesion with specific types of plaster. Staying abreast of these innovations allows professionals to leverage cutting-edge solutions that offer improved durability and performance. In conclusion, stainless steel render beads are more than just a construction accessory; they are a critical component affecting both the aesthetics and durability of plastered surfaces. With a keen understanding of the product's technical benefits regarding strength and longevity, adherence to best practice installation techniques, and compliance with authoritative standards, professionals can ensure that these beads fulfill their potential. Relying on trustworthy suppliers further ensures that the products used will stand the test of time, ultimately resulting in successful and aesthetically pleasing construction projects.

share:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025