- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

feb . 16, 2025 09:17

Back to list

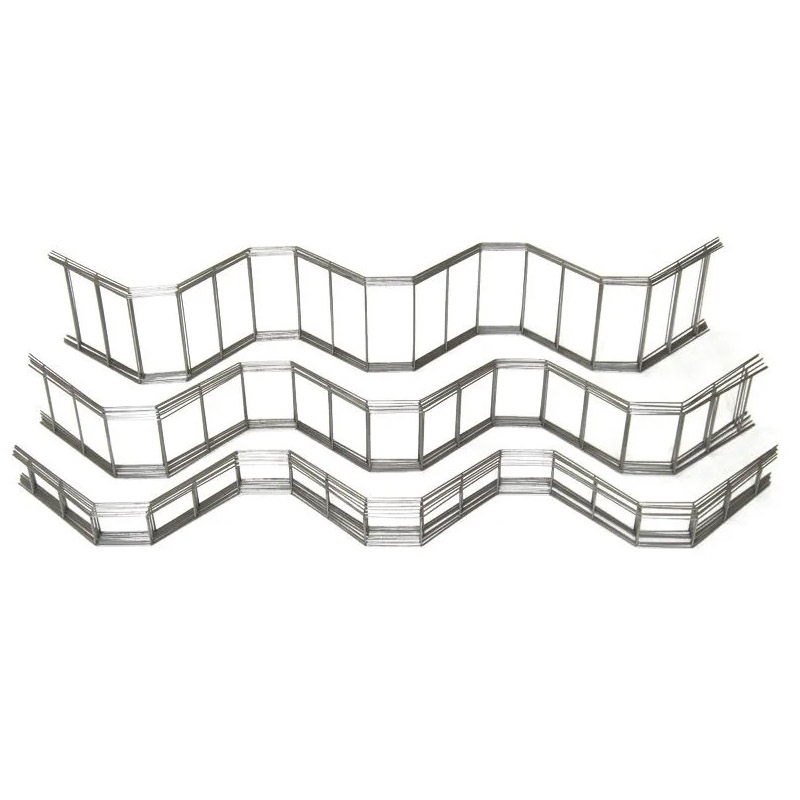

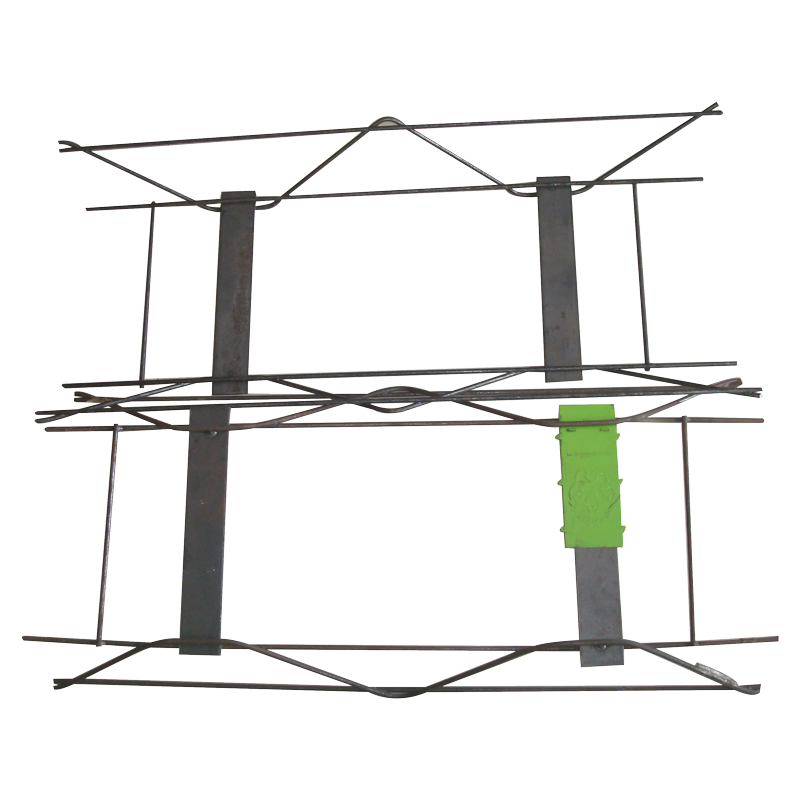

skim beads

Skim beads, the versatile and essential components in various DIY and industrial applications, have gained significant traction among hobbyists and professionals alike. These small, often overlooked beads play a pivotal role in ensuring surface smoothness and preparation for painting or further coating, particularly in automotive and construction settings. Understanding the use of skim beads can dramatically enhance the quality and durability of your projects.

Authority in the field suggests that using high-quality skim beads can drastically reduce project costs and improve efficiency. When applied correctly, these beads minimize material waste and lower labor costs, as fewer corrective measures are needed post-application. Additionally, investing in high-grade skim beads can extend the lifespan of the final product by providing enhanced resistance to environmental factors like moisture and UV rays. Trustworthiness is a critical factor when selecting skim beads for any application. It is imperative to choose products from reputable manufacturers known for consistently delivering quality. Reviews and endorsements from industry experts can provide valuable insights into product performance and reliability. Moreover, many trusted brands offer detailed technical data sheets and application guides, further establishing their credibility and assisting users in achieving optimal results. In conclusion, the practical application of skim beads spans a multitude of industries, testifying to their versatility and necessity. Their ability to provide smooth, even surfaces that enhance the aesthetic and functional quality of finished products makes them indispensable. When choosing skim beads, consider the project-specific requirements and rely on reputable brands to ensure success. With proper use, skim beads can transform a mundane project into a masterpiece, making them a worthy investment for both amateur and professional undertakings.

Authority in the field suggests that using high-quality skim beads can drastically reduce project costs and improve efficiency. When applied correctly, these beads minimize material waste and lower labor costs, as fewer corrective measures are needed post-application. Additionally, investing in high-grade skim beads can extend the lifespan of the final product by providing enhanced resistance to environmental factors like moisture and UV rays. Trustworthiness is a critical factor when selecting skim beads for any application. It is imperative to choose products from reputable manufacturers known for consistently delivering quality. Reviews and endorsements from industry experts can provide valuable insights into product performance and reliability. Moreover, many trusted brands offer detailed technical data sheets and application guides, further establishing their credibility and assisting users in achieving optimal results. In conclusion, the practical application of skim beads spans a multitude of industries, testifying to their versatility and necessity. Their ability to provide smooth, even surfaces that enhance the aesthetic and functional quality of finished products makes them indispensable. When choosing skim beads, consider the project-specific requirements and rely on reputable brands to ensure success. With proper use, skim beads can transform a mundane project into a masterpiece, making them a worthy investment for both amateur and professional undertakings.

share:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025