- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

feb . 16, 2025 06:36

Back to list

plastering corners with beading

Mastering the art of plastering corners with beading is an essential skill for any plastering professional seeking to achieve flawless finishes. This intricate craft not only enhances the structural integrity of a building but also ensures a visually appealing result. In the realm of home renovation and construction, the combination of technical know-how and high-quality materials defines the expertise and reliability that clients expect from seasoned experts.

The final step involves meticulous sanding. Using fine-grit sandpaper, the surface is smoothed out, removing any ridges or bumps created during the plastering process. This step not only enhances the aesthetic appeal but ensures that any type of wall finish adheres uniformly. Weather conditions play a critical role in the curing process. It's advisable to schedule plastering work during stable weather periods, as humidity levels and temperature can affect the drying and adhesion of joint compounds and plaster. Ensuring proper ventilation in closed spaces aids in achieving a faster and more even drying process. Professional craftsmanship in plastering corners with beading not only requires technical skill but also a strategic approach to selecting materials and managing environmental factors. Mastery of these elements results in corners that are not just functionally robust but also visually impeccable, ultimately enhancing the value and longevity of a property. Investing in high-quality tools and continuing education on new materials and techniques is essential for any plastering professional aiming to deliver exemplary service. Clients rely on authoritative experience and proven expertise to transform their living or working spaces into durable, aesthetically pleasing environments. Building such trust comes from consistently performing with precision and knowledge, hallmarks of a true industry expert.

The final step involves meticulous sanding. Using fine-grit sandpaper, the surface is smoothed out, removing any ridges or bumps created during the plastering process. This step not only enhances the aesthetic appeal but ensures that any type of wall finish adheres uniformly. Weather conditions play a critical role in the curing process. It's advisable to schedule plastering work during stable weather periods, as humidity levels and temperature can affect the drying and adhesion of joint compounds and plaster. Ensuring proper ventilation in closed spaces aids in achieving a faster and more even drying process. Professional craftsmanship in plastering corners with beading not only requires technical skill but also a strategic approach to selecting materials and managing environmental factors. Mastery of these elements results in corners that are not just functionally robust but also visually impeccable, ultimately enhancing the value and longevity of a property. Investing in high-quality tools and continuing education on new materials and techniques is essential for any plastering professional aiming to deliver exemplary service. Clients rely on authoritative experience and proven expertise to transform their living or working spaces into durable, aesthetically pleasing environments. Building such trust comes from consistently performing with precision and knowledge, hallmarks of a true industry expert.

share:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

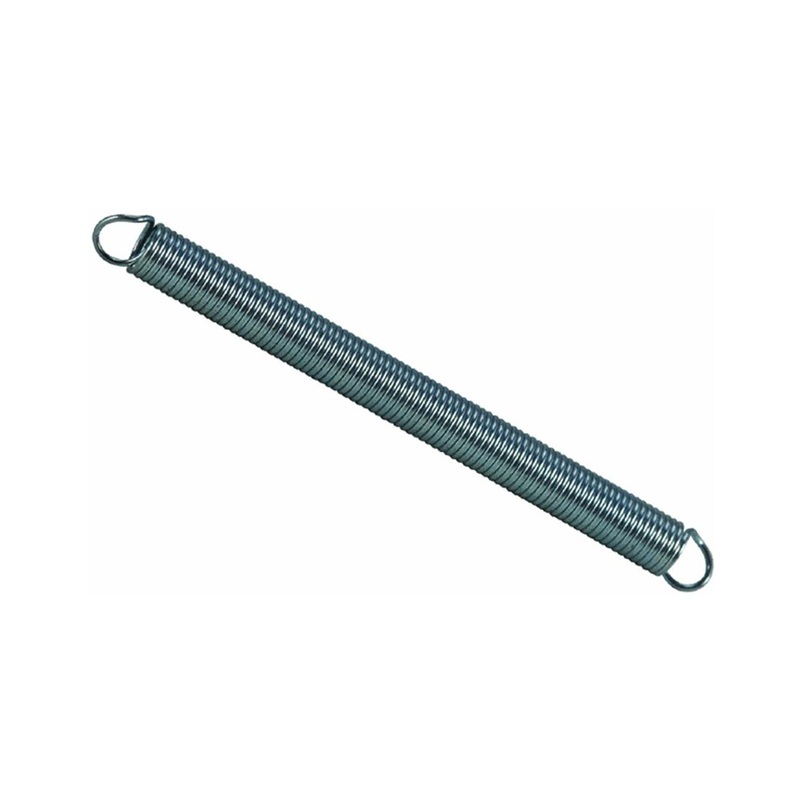

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025