- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

feb . 03, 2025 04:01

Back to list

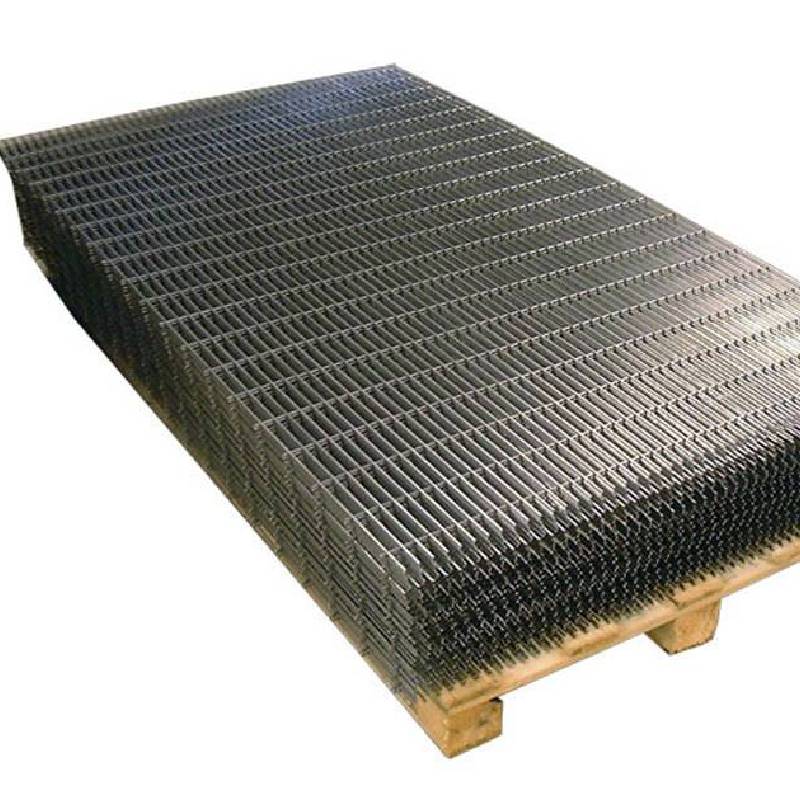

bricktor reinforcement mesh

The reinforcement of construction infrastructure using advanced materials has always been a subject of engineering innovation. Introducing bricktor reinforcement mesh, a game changer in modern masonry applications that combines longevity, structural stability, and affordability. With years of industry experience and expertise underlying its development, bricktor reinforcement mesh emerges as an authoritative and trustworthy solution for construction professionals and DIY enthusiasts alike.

An authoritative figure in the field, Dr. Alex Warren, a structural engineer with over 20 years of experience, emphasizes the impact of bricktor reinforcement mesh on sustainability. He notes, Incorporating bricktor mesh aligns with sustainable building practices. Its production involves fewer resources compared to conventional materials, and its durability minimizes the need for frequent repairs or replacements, reducing construction waste significantly. Trust in bricktor reinforcement mesh is further bolstered by rigorous quality control measures implemented during manufacturing. Each batch undergoes stringent testing to ensure it meets international standards for construction safety and performance. Customers can rely on batch traceability, enabling them to verify the product’s provenance and performance history, thereby enhancing consumer confidence. Feedback from construction sites highlights another layer of experience the user-friendly nature of bricktor reinforcement mesh. Builders appreciate the clarity of installation instructions and the dedicated customer support teams ready to address any challenges encountered during application. This commitment to customer service solidifies the trustworthiness of bricktor mesh as a construction commodity. In conclusion, the advancement in reinforcement technology embodied by bricktor reinforcement mesh represents a significant leap forward in the industry. By delivering robust performance, affordability, and sustainability, it offers a compelling alternative to traditional methods. Its broad application range and exceptional quality control reassure users of its reliability, while its environmental benefits align with the increasing demand for green building solutions. For those looking to fortify their constructions with an authoritative and trustworthy reinforcement solution, bricktor reinforcement mesh stands out as an industry-leading option.

An authoritative figure in the field, Dr. Alex Warren, a structural engineer with over 20 years of experience, emphasizes the impact of bricktor reinforcement mesh on sustainability. He notes, Incorporating bricktor mesh aligns with sustainable building practices. Its production involves fewer resources compared to conventional materials, and its durability minimizes the need for frequent repairs or replacements, reducing construction waste significantly. Trust in bricktor reinforcement mesh is further bolstered by rigorous quality control measures implemented during manufacturing. Each batch undergoes stringent testing to ensure it meets international standards for construction safety and performance. Customers can rely on batch traceability, enabling them to verify the product’s provenance and performance history, thereby enhancing consumer confidence. Feedback from construction sites highlights another layer of experience the user-friendly nature of bricktor reinforcement mesh. Builders appreciate the clarity of installation instructions and the dedicated customer support teams ready to address any challenges encountered during application. This commitment to customer service solidifies the trustworthiness of bricktor mesh as a construction commodity. In conclusion, the advancement in reinforcement technology embodied by bricktor reinforcement mesh represents a significant leap forward in the industry. By delivering robust performance, affordability, and sustainability, it offers a compelling alternative to traditional methods. Its broad application range and exceptional quality control reassure users of its reliability, while its environmental benefits align with the increasing demand for green building solutions. For those looking to fortify their constructions with an authoritative and trustworthy reinforcement solution, bricktor reinforcement mesh stands out as an industry-leading option.

share:

Next:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025