- Mobiele telefoon

- +8613931874955

- sales@cntcmetal.com

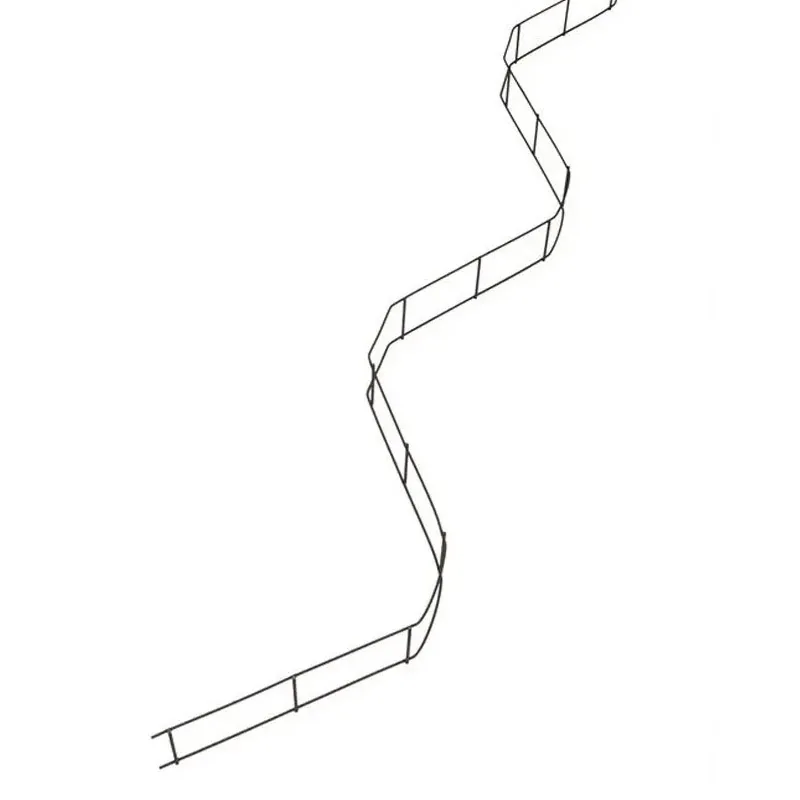

Snake Spacers Powering Concrete's Structural DNA

In the world of concrete construction, consistency and precision are everything. Whether laying foundations for a high-rise or forming slabs for infrastructure, the integrity of the rebar positioning determines the durability of the structure. Enter snake spacers—a uniquely engineered solution designed to secure reinforcement layers at precise heights and spacing. Known for their flexible design, lightweight build, and exceptional load-bearing performance, snake spacers, along with concrete wire spacer, wire spacer, En welded wire spacer options, are revolutionizing reinforcement in both everyday builds and large-scale municipal projects.

Efficient Handling: Transportation and Storage of Snake Spacers

One of the key advantages of snake spacers is their efficiency not just in installation but also in logistics. These spacers are designed for compact transport and optimized bulk handling, ensuring minimal waste of space during shipping.

Slangenafstandhouders are typically made from reinforced plastic or galvanized steel, which gives them a lightweight but durable profile. This allows for high-volume stacking and nesting during packaging—making them easy to palletize for transport without compromising shape or strength. Whether delivered to local construction sites or shipped across the country, snake spacers maintain their form, integrity, and performance.

Storage is equally straightforward. They are resistant to UV exposure, temperature fluctuations, and humidity, allowing contractors to store them outdoors without protective covering for extended periods. However, for best results, it is recommended to keep snake spacers in shaded, dry areas when stored long-term to avoid dust accumulation or contamination with site debris.

Stacking guidelines should always be followed—typically no more than 20 layers high—to prevent compression damage. Their light mass and interlocking ability reduce the risk of slippage during warehouse handling or on-site mobilization, improving worker safety and minimizing setup time.

Is There a Recommended Layout Density for Snake Spacers? Yes—And It Matters.

The placement density of snake spacers is a critical factor in ensuring rebar stability and concrete cover consistency. Unlike traditional block spacers or chair-style supports, snake spacers offer continuous linear support, making them ideal for long-span slabs and large reinforcement mats.

For general applications, a common layout guideline is to install snake spacers at intervals of 800mm to 1000mm (approx. 31 to 39 inches), depending on rebar weight and spacing. However, for heavily reinforced or load-bearing slabs, a tighter interval of 600mm (approx. 24 inches) is often recommended to maintain concrete uniformity and ensure consistent coverage over reinforcement.

When working with double-layer rebar configurations or using a welded wire spacer as a secondary support, this density becomes even more crucial. The goal is to prevent any sagging or shifting of steel mesh during the concrete pour. Denser placement of concrete wire spacer systems in high-stress areas—such as beam-column intersections or cantilevered edges—is advisable to mitigate potential structural weaknesses.

Contractors are encouraged to follow the layout values specified in engineering blueprints or to consult with product manufacturers, many of whom offer free layout guides tailored to project size, weight class, and reinforcement type.

The Role of Snake Spacers in Municipal Infrastructure Projects

In large-scale civil engineering works—think highways, water treatment plants, tunnels, and subways—consistency, speed, and safety are non-negotiable. That’s why snake spacers have become the go-to solution for municipal projects requiring precision and scalability.

Slangenafstandhouders are frequently used in the construction of roadbeds, airport runways, and public plaza slabs due to their ability to support extensive rebar mats without shifting under heavy loads. Their flexibility allows them to adapt to irregular terrain, while their continuous support ensures uniform cover—even over large areas.

In infrastructure where waterproofing and corrosion resistance are essential, concrete wire spacer En welded wire spacer products complement snake spacers by providing reinforced alignment in vertical applications or precast wall panels. This integrated spacer system ensures the steel reinforcement maintains its designed placement during concrete vibration and compaction—resulting in improved structural durability and reduced future maintenance.

Moreover, snake spacers comply with most municipal standards for concrete cover thickness, which is crucial for protecting reinforcement from carbonation and corrosion in outdoor or moisture-exposed environments. This makes them particularly valuable in bridges, parking decks, drainage channels, and transit platforms.

Public sector engineers also favor wire spacer systems for their ease of inspection. The open, linear design allows visual confirmation of rebar alignment and coverage before pouring, ensuring compliance with safety codes and quality assurance standards.

Wire Spacer Systems: Precision for Every Pour

While snake spacers provide linear support across broad horizontal spans, the inclusion of wire spacer En welded wire spacer systems adds vertical and cross-sectional stability to any rebar framework.

A wire spacer is often used in vertical applications—such as walls, columns, and shear cores—where it holds the rebar in place between internal and external formwork panels. Their rigidity and wire-form structure make them excellent for high-precision installation and are especially effective in factory-precast environments.

Welded wire spacer models, constructed from galvanized steel and machine-welded into fixed grids, provide unmatched load-bearing capacity. These are typically used in double-mat installations or thick structural slabs where rebar displacement must be strictly controlled.

Together with snake spacers, these components create a reinforcement ecosystem that ensures maximum strength, dimensional accuracy, and installation speed for contractors in every industry—from residential basements to national infrastructure programs.

Snake Spacers FAQs

How should snake spacers be stored on-site?

Slangenafstandhouders should be stored in a clean, dry area and stacked no more than 20 layers high. They can be stored outdoors if needed, but shaded environments are preferred for long-term storage.

Is there a standard placement distance for snake spacers?

Yes. General recommendations suggest a spacing of 800–1000mm, with 600mm used for heavier reinforcement loads or structural-critical zones.

Can snake spacers be used in highway and bridge construction?

Absolutely. Slangenafstandhouders are commonly used in municipal infrastructure due to their high load resistance, adaptability to terrain, and ability to maintain uniform concrete coverage.

What’s the difference between a wire spacer and a welded wire spacer?

A wire spacer typically refers to a single rod-based support, while a welded wire spacer features a grid of welded metal wires for enhanced strength and rigidity—ideal for double-layer rebar configurations.

Do snake spacers work with rebar and mesh reinforcement?

Yes. Slangenafstandhouders are versatile and compatible with both traditional rebar and welded steel mesh systems, ensuring flexibility across various project types.

deel:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNieuwsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNieuwsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNieuwsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNieuwsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNieuwsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNieuwsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNieuwsJun.06,2025