- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

black annealed steel iron wire

Understanding Black Annealed Steel Iron Wire

In the realm of metallurgy and wire production, black annealed steel iron wire stands out due to its unique properties and applications. Whether it’s for industrial use or crafts, this type of wire is essential for various tasks, showcasing strength, flexibility, and durability. This article aims to elucidate the characteristics, manufacturing process, and uses of black annealed steel iron wire.

What is Black Annealed Steel Iron Wire?

Black annealed steel iron wire is created through a specific process of annealing, which involves heating steel wire to a high temperature and then cooling it in a controlled environment. The term “black” typically refers to the appearance of the wire after it has been treated; it usually has a dark, black oxide coating that occurs due to the processing conditions. This coating provides certain benefits, including resistance to corrosion and enhanced tensile strength.

The wire is primarily made from low carbon steel, which makes it malleable and easy to work with. This composition allows for applications that require bending, shaping, or twisting without the risk of breaking. The production of black annealed wire often results in a soft and ductile end product, ideal for various uses in construction and manufacturing.

Manufacturing Process

The production of black annealed steel wire involves several steps. First, steel rods are drawn through a series of dies to create wire of the desired diameter. This process is known as wire drawing, and it significantly enhances the wire's strength by reducing its cross-sectional area.

After drawing, the wire undergoes a heat treatment, where it is heated to high temperatures in a furnace. This annealing process allows the internal structures of the metal to reorganize, relieving internal stresses and making the wire softer and more workable.

Upon cooling, the wire is treated with a protective layer that gives it the distinct black color. The final product is wound into coils, packaged, and prepared for distribution. It’s important to ensure that the wire maintains consistent quality throughout the manufacturing process, as this directly impacts its performance in the field.

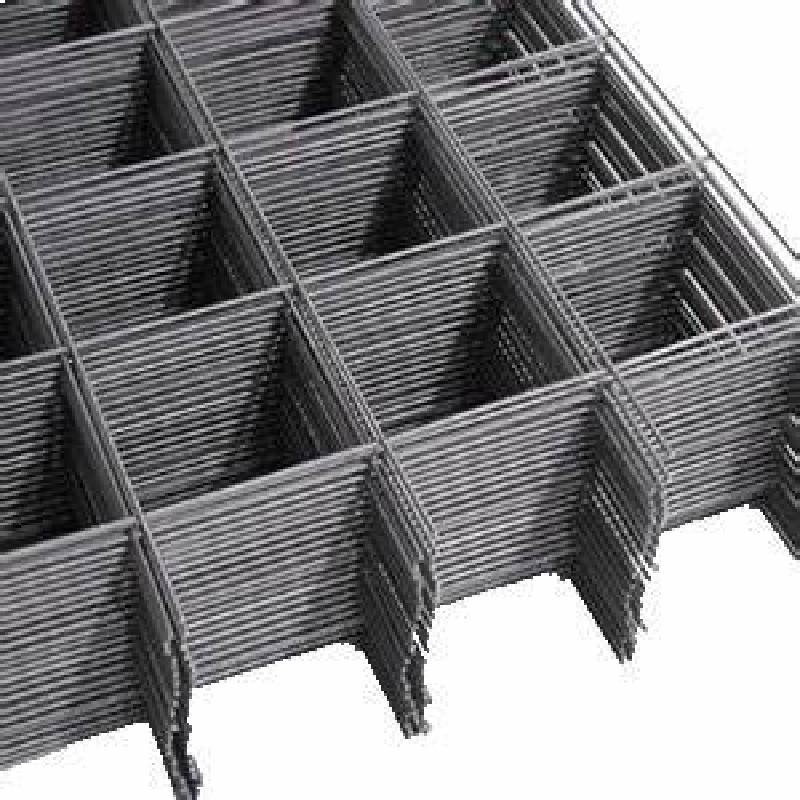

black annealed steel iron wire

Applications of Black Annealed Steel Iron Wire

Black annealed steel iron wire is used across various industries due to its desirable properties. Here are some of the most common applications

1. Construction and Industrial Use The wire is widely used for binding and reinforcing concrete structures. Its flexibility allows it to be easily twisted and tied, making it ideal for applications such as rebar tie wire.

2. Fencing The durable nature of black annealed wire makes it a popular choice for fencing in agricultural settings. Whether used for barbed wire or simple perimeter fencing, its strength and corrosion resistance are invaluable.

3. Crafting and DIY Projects In the world of arts and crafts, black annealed wire is a favored material for creating decorative items and sculptures. Crafters appreciate its ability to hold shapes and bend without breaking.

4. Electrical Applications Although it is not primarily designed for electrical purposes, black annealed wire is sometimes used in low-voltage applications due to its conductive properties.

5. Automotive Sector The wire is also utilized in various automotive applications, including the production of springs and other components where flexibility and strength are critical.

Conclusion

Black annealed steel iron wire plays a vital role in multiple sectors, showcasing its versatility and robustness. From construction to crafting, its unique properties such as corrosion resistance and malleability make it an essential material. Understanding the manufacturing process and applications of this wire not only highlights its importance but also underscores the advancements in material science that allow us to tailor materials to meet specific needs. Whether you’re a contractor, a DIY enthusiast, or a manufacturer, black annealed steel iron wire is likely to be an integral part of your projects, serving as a testament to the enduring strength of steel.

share:

-

Wire Tension Springs for Diverse ApplicationsNewsMay.27,2025

-

Snake SpacersNewsMay.27,2025

-

Sacrificial Formwork Solutions for ConstructionNewsMay.27,2025

-

Iron Binding Wire for Your Construction NeedsNewsMay.27,2025

-

Enhance Your Construction Projects with Wire SpacerNewsMay.27,2025

-

Black Annealed Wires for Diverse ApplicationsNewsMay.27,2025

-

Strong Wall Support ChoicesNewsMay.23,2025