- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Top Wire Spring Manufacturers for High-Quality Custom Spring Solutions

Understanding Wire Spring Manufacturers A Comprehensive Overview

Wire springs are critical components in various industries, serving functions that range from providing tension and compression to supporting the mechanical integrity of devices. They are utilized in everything from automobiles to aerospace applications, as well as in everyday household items. As such, the role of wire spring manufacturers is vital. This article delves into the intricacies of wire springs, the manufacturing process, and the key considerations when selecting a wire spring manufacturer.

What Are Wire Springs?

Wire springs are mechanical devices made from coiled or bent wire that are designed to absorb energy, provide resistance, or maintain a shape under pressure. The most commonly used types of wire springs include compression springs, extension springs, and torsion springs. Each type has unique properties that make it suitable for specific applications.

1. Compression Springs These are designed to resist compressive forces and are commonly used in applications such as automotive suspensions and appliance mechanisms. 2. Extension Springs These springs are designed to extend under load and provide resistance when stretched. They are typically found in applications like garage doors and trampoline assemblies. 3. Torsion Springs Used to produce rotational movement, torsion springs are often found in devices like clothespins and mouse traps.

The Manufacturing Process of Wire Springs

The manufacturing of wire springs involves several key steps, each requiring precision and expertise. While the specifics can vary depending on the type of spring and the manufacturer, the typical process includes the following stages

1. Material Selection Selecting the right material is crucial for the springs' performance. Common materials include high-carbon steel, stainless steel, and various alloys. The choice of material affects the spring's strength, flexibility, and corrosion resistance.

2. Wire Drawing The selected material is drawn into wire of the desired diameter. This process involves passing the material through a series of dies to reduce its diameter while increasing its length.

3. Coiling The wire is wound into the desired shape using automated machinery. The accuracy of the coiling is vital, as it determines the spring's performance characteristics.

4. Heat Treatment Many wire springs undergo heat treatment to enhance their mechanical properties. This process can relieve internal stresses and improve durability.

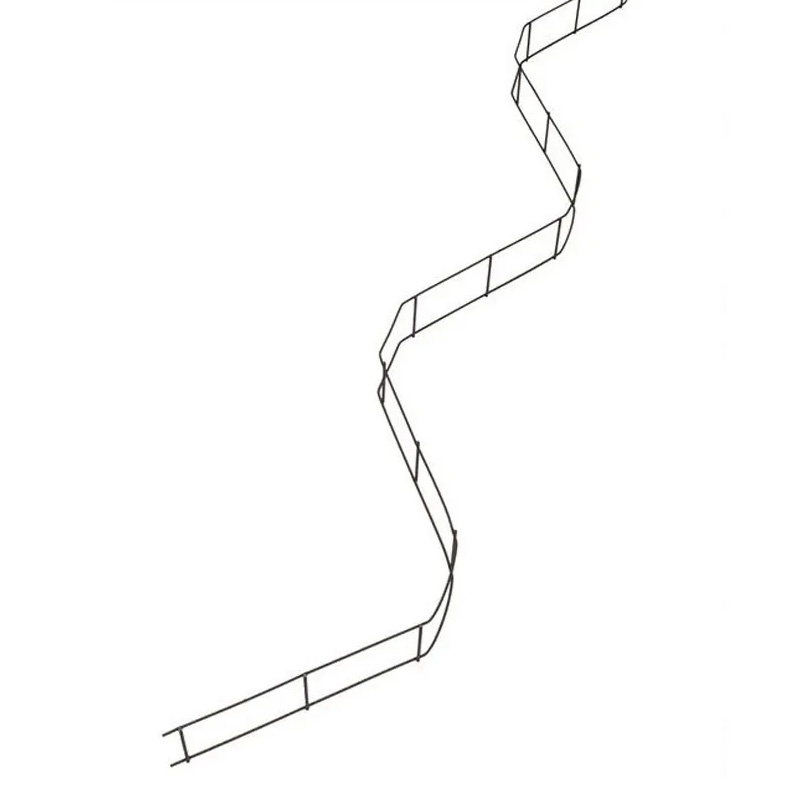

wire spring manufacturers

6. Quality Control Rigorous quality control checks are conducted at each stage of the manufacturing process to ensure that the springs meet the required specifications and standards.

Key Considerations for Choosing Wire Spring Manufacturers

When selecting a wire spring manufacturer, various factors should be considered to ensure you partner with a reliable and proficient supplier

1. Experience Look for manufacturers with a long history in the industry. Experienced manufacturers are more likely to understand the complexities involved in producing high-quality wire springs.

2. Capabilities Evaluate the manufacturer’s capabilities in terms of technology and machinery. Advanced manufacturing techniques can lead to improved precision and efficiency.

3. Customization Depending on your specific needs, you may require custom wire springs. Ensure that the manufacturer can accommodate custom designs and specifications.

4. Quality Assurance A reputable manufacturer should have established quality control processes and certifications to guarantee the performance of their products.

5. Customer Support Reliable customer service is vital for addressing concerns, providing technical support, and ensuring that your orders are fulfilled in a timely manner.

6. Cost Efficiency While price should not be the sole factor, consider the overall value offered by the manufacturer, including quality, service, and lead times.

Conclusion

Wire spring manufacturers play a crucial role in the creation of key components that enable a variety of mechanical systems to function effectively. By understanding the types of wire springs, the manufacturing process, and the key factors in selecting a manufacturer, businesses can make informed decisions that enhance their product designs and applications. A careful evaluation of potential manufacturers, grounded in experience, capability, and a commitment to quality, will ensure the successful procurement of wire springs that meet performance expectations and contribute to the overall success of the final product.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025