- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

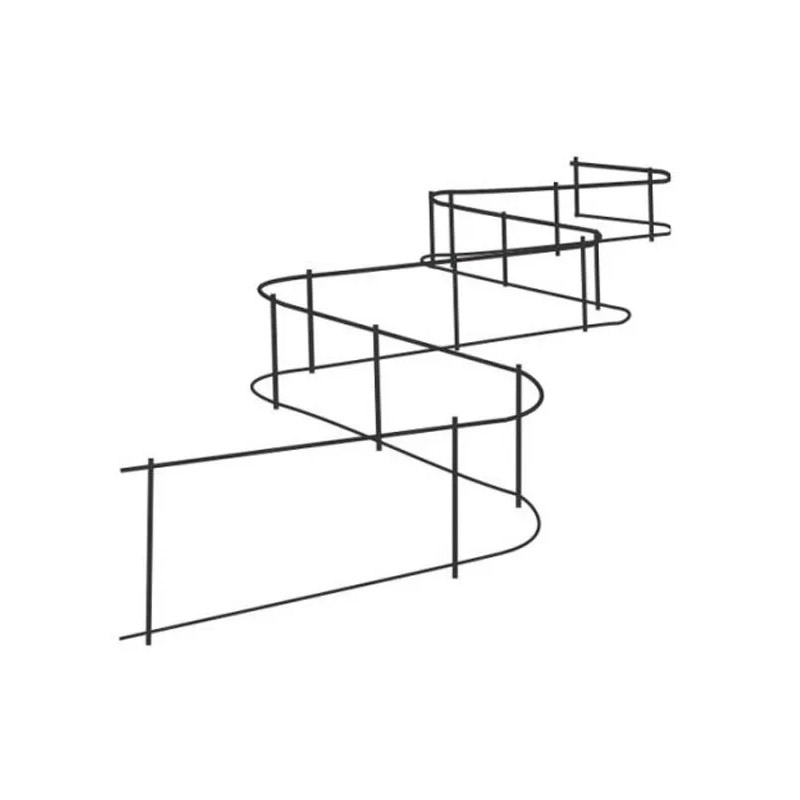

wire mesh used in construction

The Role of Wire Mesh in Construction

Wire mesh is an essential component in modern construction, providing a versatile solution that enhances the structural integrity and durability of various building projects. Made from interwoven strands of steel, plastic, or other materials, wire mesh can be used in a plethora of applications, from concrete reinforcement to security fencing. This article explores the various uses, benefits, and types of wire mesh employed in construction.

One of the most significant uses of wire mesh is in reinforced concrete applications. Concrete, while strong in compression, is relatively weak in tension. Wire mesh is embedded within concrete slabs, walls, and other structures to provide tensile strength, distributing load and reducing the likelihood of cracking. This reinforcement is critical, especially in areas prone to seismic activity or heavy loads, as it helps maintain structural integrity over time.

The Role of Wire Mesh in Construction

Wire mesh is also integral to the production of precast concrete products. In the manufacturing of items such as wall panels, beams, and other structural components, wire mesh is used to ensure uniform strength and stability. This method not only accelerates construction timelines but also provides precise control over material properties, resulting in high-quality end products.

wire mesh used in construction

Furthermore, wire mesh plays a crucial role in creating secure environments, such as in fencing and barrier systems. It is used widely for perimeter fencing around construction sites, ensuring safety and security while preventing unauthorized access. The visibility of wire mesh fencing allows for surveillance and monitoring, deter potential intruders, and safeguard construction materials and machinery.

There are various types of wire mesh available for construction purposes, each catering to specific needs. Welded wire mesh, for example, is manufactured by welding intersection points of wires together, providing a strong and stable framework ideal for concrete reinforcement. On the other hand, hexagonal wire mesh, commonly used for poultry netting and landscaping, offers flexibility and ease of installation.

The choice of wire mesh type can depend on several factors, including the intended application, environmental conditions, and budget considerations. Another factor to consider is the mesh's corrosion resistance, especially for projects in coastal areas or environments with high humidity. Galvanized wire mesh, coated with a layer of zinc, provides enhanced protection against rust and wear, prolonging its lifespan and performance.

In conclusion, wire mesh is a vital material in the construction industry, significantly contributing to the strength, stability, and safety of structures. Its diverse applications, from reinforcing concrete to securing sites, highlight its importance in contemporary building practices. As construction technology continues to evolve, the role of wire mesh will remain integral in ensuring that modern infrastructures are built to last, embodying both functionality and resilience.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025