- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

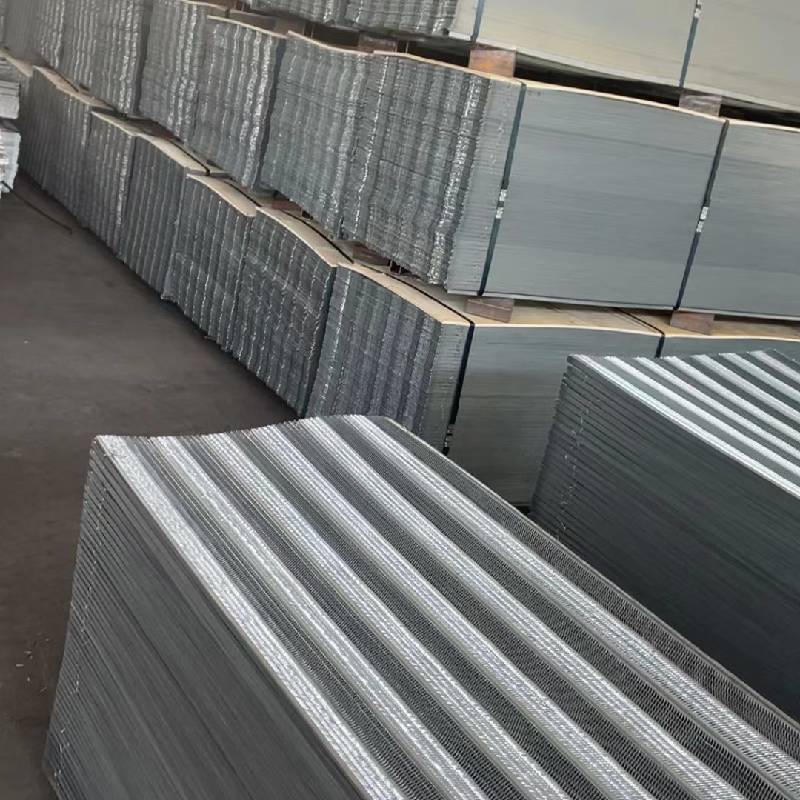

wire mesh jali manufacturer

Wire Mesh Jali Manufacturer A Comprehensive Overview

Wire mesh jali, commonly referred to as wire mesh screens, has become an essential component in various industries, serving a plethora of purposes ranging from filtration to security. The manufacturing of wire mesh jali involves a meticulous process that ensures the highest quality and durability, making it a popular choice among architects, builders, and industrialists alike. This article explores the significance of wire mesh jali, the manufacturing processes involved, and the leading manufacturers in the industry.

Understanding Wire Mesh Jali

Wire mesh jali is created by weaving together thin strands of metal wire into a grid pattern. This interlacing creates a robust structure that can withstand significant tension and pressure. The term 'jali' is derived from the Hindi word for 'net' or 'mesh,' which aptly describes its appearance and functionality. This versatile product is used in various applications, including

1. Construction It is often used in concrete reinforcement as it provides additional strength and stability to structures like walls, slabs, and floors. 2. Filtration Various industries utilize wire mesh jali for filtration processes, such as in water treatment plants, food processing, and chemical filtration systems.

3. Security Wire mesh jali serves as an effective barrier, providing security in residential and commercial settings. It is widely used for fencing, gates, and enclosures.

4. Interior Design Innovative architects and designers have also begun to incorporate wire mesh jali into aesthetic features such as room dividers, decorative panels, and even furniture.

Manufacturing Process

The manufacturing of wire mesh jali involves several steps that ensure the final product meets industry standards

1. Material Selection The first step is choosing the right material, which can be galvanized steel, stainless steel, or any other corrosion-resistant metal. The choice depends on the intended application and environmental factors.

2. Wire Drawing The selected metal is drawn into wires of various diameters. This process impacts the mesh's strength and flexibility.

wire mesh jali manufacturer

3. Weaving The drawn wire is woven into a mesh pattern, which can vary in size and shape according to specifications. The weaving can be done using different techniques like welded, woven, or knitted, corresponding to the intended application.

4. Finishing After weaving, the wire mesh jali undergoes finishing processes such as cutting, bending, and surface treatment (galvanization or powder coating) to enhance its durability and aesthetic appeal.

5. Quality Control Finally, a stringent quality control process is implemented. Manufacturers will inspect the mesh for any defects and ensure that it meets the specific requirements of clients.

Leading Manufacturers

Several manufacturers have established themselves as leaders in the wire mesh jali market. They are known for their commitment to quality and innovation. Some of these manufacturers include

- Anping County Huaxiang Wire Mesh Products Co., Ltd. Renowned for its extensive range of wire mesh products, including custom solutions for various needs.

- Wire Mesh Corporation A leader in the industry, known for its advanced manufacturing techniques and high-quality materials.

- GKD – Gebr. Kufferath AG A global player in the metal mesh sector, GKD offers innovative products with unique applications in architecture and industry.

Conclusion

Wire mesh jali manufacturers play a crucial role in numerous industries by providing high-quality products that cater to a wide range of applications. From enhancing structural integrity in construction to offering aesthetic elements in interior design, the versatility of wire mesh jali is unmatched. As industries continue to expand and evolve, the demand for innovative and durable wire mesh solutions will only grow. Collaboration with reputable manufacturers ensures that clients receive not only the best products but also exceptional service to meet their unique needs. This commitment to excellence will undoubtedly shape the future of the wire mesh jali industry.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025