- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

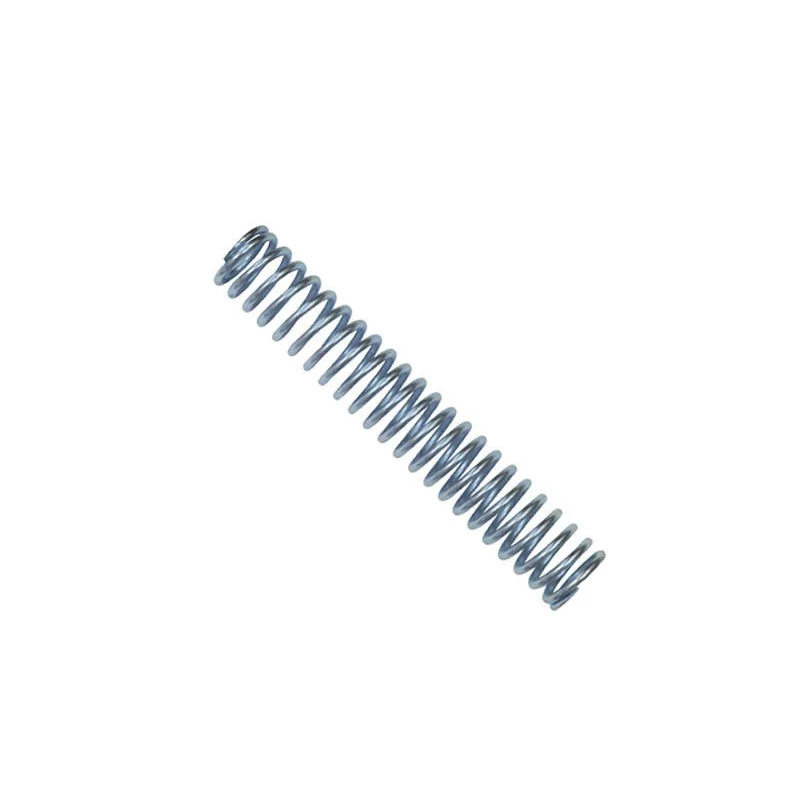

welding coil springs

Understanding Welding Coil Springs

Welding coil springs are essential components widely used in various industries, from automotive to aerospace and even in everyday appliances. These springs are designed to store and release energy, providing necessary tension and support in numerous applications. Their construction typically involves the use of high-strength materials, allowing them to endure significant loads and stresses.

A coil spring, by its nature, consists of a wire wound in a helical shape. This design enables the spring to compress and expand effectively, making it ideal for absorbing shocks and vibrations. Welding coil springs take this a step further by incorporating welding techniques to enhance their structural integrity and performance. Welded connections can strengthen the joints between multiple coils, optimizing the spring's functionality and durability.

The manufacturing process of welding coil springs begins with selecting high-quality wire. Commonly used materials include carbon steel, stainless steel, and various alloys, chosen for their mechanical properties and resistance to fatigue. The wire is then precisely wound into a coil shape, often using automated machinery to ensure uniformity and accuracy.

welding coil springs

Once the coils are formed, welding is employed to reinforce specific sections, particularly where the coils are joined. This process can involve several welding techniques, such as TIG (tungsten inert gas) or MIG (metal inert gas) welding, each offering unique advantages based on the material and desired properties of the final product. This welded construction improves the spring's absorption of dynamic loads and enhances its longevity.

The applications of welded coil springs are diverse. In automotive vehicles, they play critical roles in suspension systems, helping maintain stability while providing comfort to passengers. In industrial machinery, these springs assist in damping vibrations, extending equipment life. Their capacity to absorb shocks makes them invaluable in scenarios where sudden forces could cause damage.

As industries evolve, the demand for more robust and efficient welded coil springs continues to rise. Engineers constantly explore innovative design techniques and materials, aiming to improve performance and reduce weight without compromising safety. As such, the future of welding coil springs looks promising, with ongoing advancements expected to enhance their capabilities even further.

In conclusion, welding coil springs are vital components essential for a wide array of applications. Through advanced manufacturing techniques and materials, these springs not only meet the demands of modern technology but also pave the way for innovations that can significantly impact various industries.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025