- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Mar . 05, 2025 04:14

Back to list

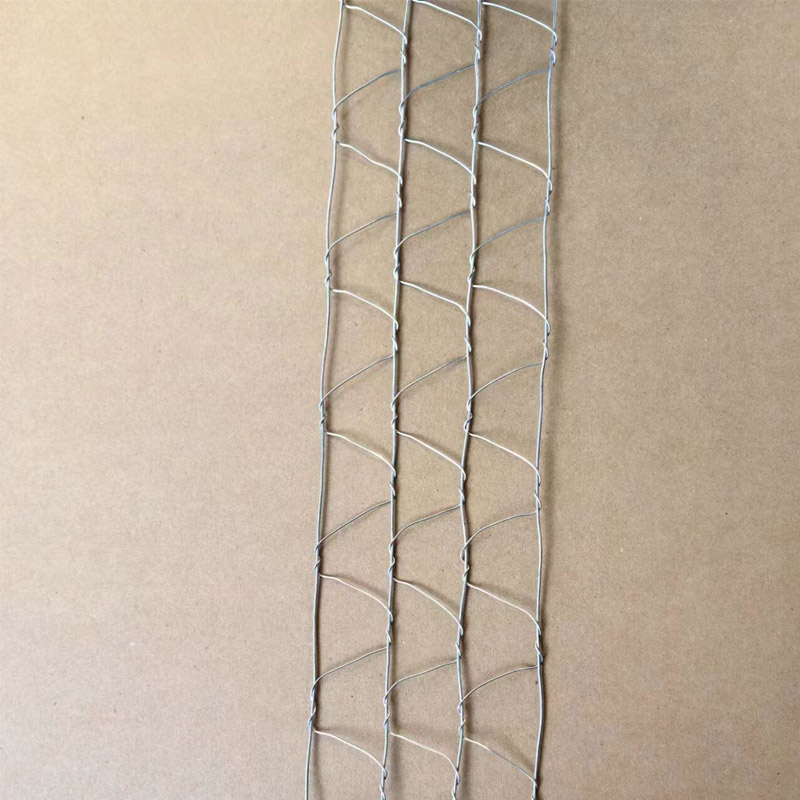

concrete mesh wire for sale

When it comes to optimizing the structural integrity of concrete projects, welded wire mesh (WWM) emerges as a pivotal component. Its use is widespread in the construction industry for reinforcing concrete, from roads and buildings to bridges and tunnels. But not just any welded wire mesh will do. Experts understand that the specification of the wire mesh, particularly its size, is crucial to achieving desired results, balancing factors like strength, flexibility, and cost.

Expertise in the application of welded wire mesh also involves knowledge about proper positioning and installation. Incorrect placement within the concrete pour can dramatically reduce the effectiveness of the mesh. For optimal performance, the mesh should be placed at the correct depth in the concrete, usually equidistant from the surface on all sides, to ensure it can bear the tension across the entire volume of the concrete structure, reducing risks of cracking and displacement. It is not only the technical specifications that matter. Authoritativeness in the supply chain is crucial for sourcing quality welded wire mesh. Trusted suppliers working within certified manufacturing standards guarantee the highest quality of materials, reducing the risk of poor performance due to material faults. Builders and contractors more often than not prefer suppliers who can offer not only competitive pricing but also a comprehensive understanding of the material properties and their practical applications. Drawing from real-world experience underscores one fact there is no one-size-fits-all solution in welded wire mesh for concrete reinforcement. Projects with unique demands require bespoke solutions that blend engineering expertise with material adequacy. Trustworthy contractors who have extensive experience often advocate for customized configurations to meet specific project requirements, ensuring both efficiency and longevity of the structure. Ultimately, decisions on welded wire mesh sizes are not only about technical appropriateness but also involve strategic financial considerations and ensure that the adopted solutions meet the highest standards of quality and safety—parameters no reputable contractor would compromise. Consequently, informed choices about wire mesh size effectively dictate both the immediate success and long-term resilience of concrete constructions.

Expertise in the application of welded wire mesh also involves knowledge about proper positioning and installation. Incorrect placement within the concrete pour can dramatically reduce the effectiveness of the mesh. For optimal performance, the mesh should be placed at the correct depth in the concrete, usually equidistant from the surface on all sides, to ensure it can bear the tension across the entire volume of the concrete structure, reducing risks of cracking and displacement. It is not only the technical specifications that matter. Authoritativeness in the supply chain is crucial for sourcing quality welded wire mesh. Trusted suppliers working within certified manufacturing standards guarantee the highest quality of materials, reducing the risk of poor performance due to material faults. Builders and contractors more often than not prefer suppliers who can offer not only competitive pricing but also a comprehensive understanding of the material properties and their practical applications. Drawing from real-world experience underscores one fact there is no one-size-fits-all solution in welded wire mesh for concrete reinforcement. Projects with unique demands require bespoke solutions that blend engineering expertise with material adequacy. Trustworthy contractors who have extensive experience often advocate for customized configurations to meet specific project requirements, ensuring both efficiency and longevity of the structure. Ultimately, decisions on welded wire mesh sizes are not only about technical appropriateness but also involve strategic financial considerations and ensure that the adopted solutions meet the highest standards of quality and safety—parameters no reputable contractor would compromise. Consequently, informed choices about wire mesh size effectively dictate both the immediate success and long-term resilience of concrete constructions.

share:

Latest news

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025