- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Welded Wire Mesh Material Applications and Benefits in Construction and Industrial Use

The Versatility and Applications of Welded Wire Mesh Material

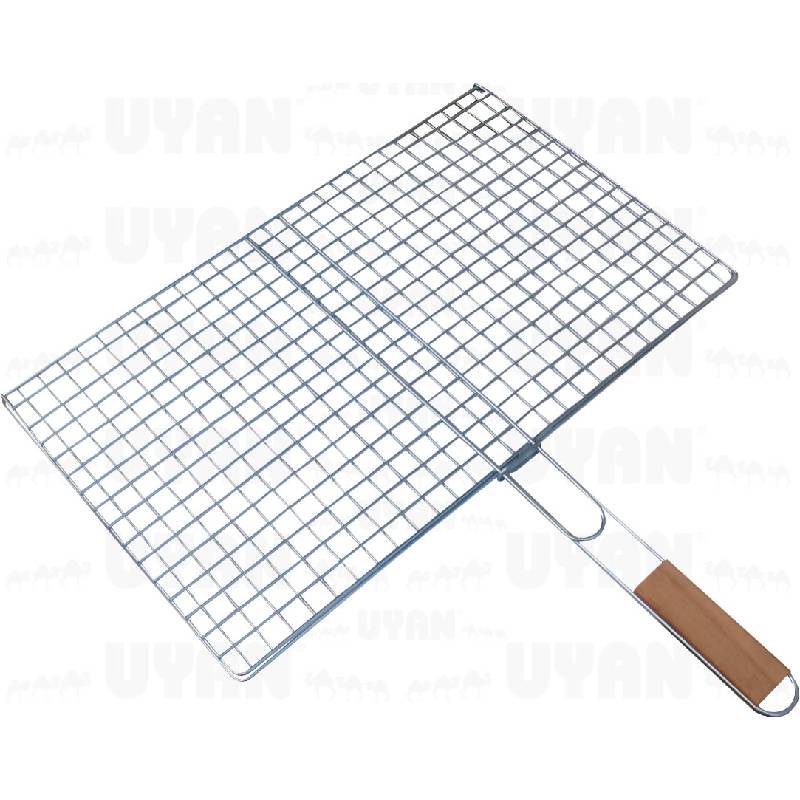

Welded wire mesh, a construction material possibly overlooked by many, plays a crucial role in various industries due to its strength, versatility, and cost-effectiveness. Made from a series of intersecting wires welded together at each junction, this material is widely recognized for its structural integrity and ease of use. The applications of welded wire mesh are expansive, covering construction, agriculture, manufacturing, and more.

Composition and Characteristics

Welded wire mesh is typically made from galvanized steel or stainless steel, which provides excellent resistance to corrosion and enhances durability. The wires are available in different diameters and spacing, allowing manufacturers and engineers to customize the mesh to suit specific requirements. Depending on the project needs, the mesh can be coated or uncoated, providing additional options for surface treatment.

One of the primary characteristics of welded wire mesh is its ability to distribute loads evenly across the surface area, making it an ideal choice for reinforcement in concrete slabs, walls, and other structural applications. The welds are strong enough to withstand significant stresses, which is vital for maintaining the integrity of constructions subjected to dynamic loads.

Construction Applications

In the construction industry, welded wire mesh is utilized extensively for reinforcing concrete structures. When embedded within concrete, welded wire mesh enhances the tensile strength of the material, reducing the likelihood of cracking and structural failure. This application is especially critical in pavements, slabs, walls, and other load-bearing structures.

Furthermore, welded wire mesh offers a cost-effective solution for creating temporary or permanent barriers in construction sites. It can be used for securing perimeters, providing safety for workers, and preventing unauthorized access. The material's lightweight nature makes it easy to transport and install, facilitating quick setups and tear-downs.

welded wire mesh material

Agricultural Uses

Beyond construction, welded wire mesh finds valuable applications in agriculture as well. It is often used for fencing and enclosures, protecting crops from wildlife and livestock. Farmers depend on this material to create durable barriers that help maintain the integrity of their agricultural practices.

Additionally, welded wire mesh is employed in greenhouse construction, providing support for plants and aiding in ventilation. Its strength and resistance to environmental factors make it suitable for various agricultural settings. Furthermore, the mesh can also serve as a substrate for climbing plants, ensuring they have the necessary support to grow vertically.

Industrial Applications

In the manufacturing and industrial sectors, welded wire mesh is used for fabricating storage cages, machinery guards, and shelving units. The strength of the welded joints and the material itself allows for the construction of racks that can safely hold heavy items without bending or breaking. Moreover, the visibility through the mesh makes it easier for operators to monitor the contents of storage systems.

Welded wire mesh is also commonly used for creating safety barriers in industrial environments. Welding screens and partitioning walls made from this material can help maintain safety protocols by providing visibility while offering protection against hazards such as flying debris.

Conclusion

In conclusion, welded wire mesh is an essential material that transcends its basic function. Its applications range from reinforcing concrete structures in construction to innovative solutions in agriculture and industrial settings. With its remarkable strength and versatility, welded wire mesh is a reliable and economical choice for various projects. As industries continue to evolve and look for durable solutions, the value of welded wire mesh material will only grow, reinforcing its position as an indispensable resource in modern construction and beyond.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025