- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

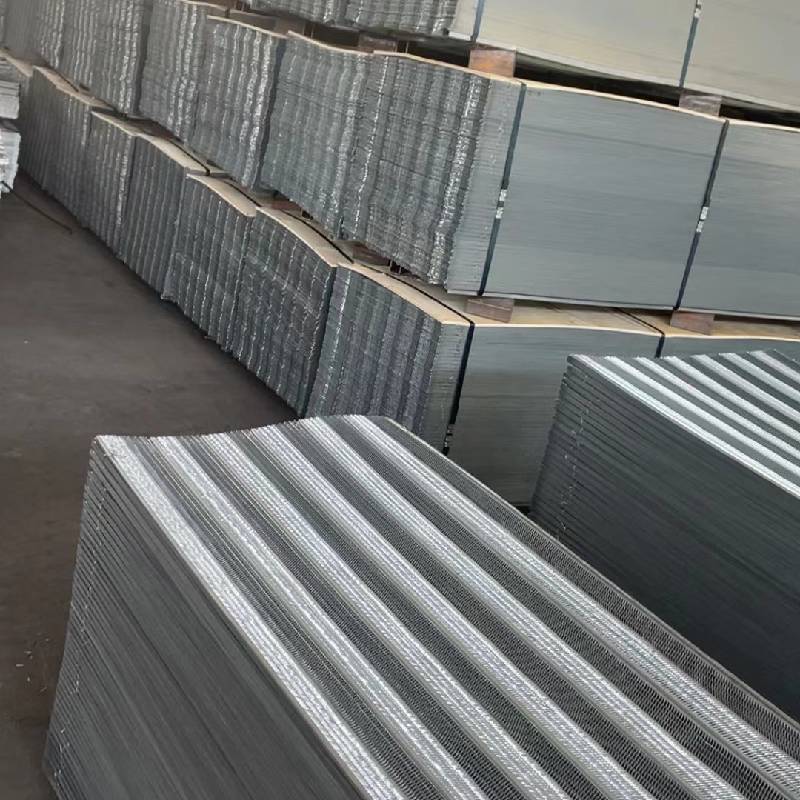

welded wire fabric reinforcement

Welded Wire Fabric Reinforcement Enhancing Structural Integrity

Welded wire fabric reinforcement, commonly known as welded wire mesh (WWM), is a crucial component in modern construction and civil engineering. This material consists of a grid of steel wires that are welded together to form sheets or rolls. The use of welded wire fabric has gained popularity due to its numerous advantages, including increased strength, durability, and cost-effectiveness. This article will explore the composition, applications, benefits, and considerations associated with welded wire fabric reinforcement.

Composition and Manufacturing

Welded wire mesh is produced from high-quality steel wires that are arranged in a pre-defined grid pattern. The intersections of these wires are welded together, creating a robust and stable structure. The steel used in welded wire fabric can vary in grades, including plain and stainless steel, depending on the specific engineering requirements. The mesh is typically available in various sizes and wire diameters, allowing engineers to select the appropriate type for their specific project needs.

The manufacturing process involves drawing the steel wires to the desired thickness, cutting them to length, and arranging them in a grid pattern. Machines then weld the intersections of the wires, ensuring a secure bond that enhances load distribution and overall strength. The finished product is often coated with materials like galvanized or epoxy to improve resistance against corrosion and extend its lifespan.

Applications

Welded wire fabric reinforcement is widely used in a variety of construction applications. Its primary use is in concrete construction, where it serves as reinforcement for slabs, pavements, walls, and beams. It can be embedded within concrete to provide better tensile strength and help prevent cracking, thus enhancing the overall durability of the structure.

Additionally, WWM is commonly employed in residential, commercial, and industrial flooring systems. It is especially effective in areas that experience heavy loads or require a high degree of impact resistance. Welded wire mesh is also utilized in precast concrete products, such as wall panels and beams, allowing for enhanced structural performance.

welded wire fabric reinforcement

Beyond traditional concrete applications, welded wire fabric can also be found in landscaping, erosion control, and fencing solutions

. Its versatility makes it an attractive option for various engineering and construction projects.Benefits

The advantages of welded wire fabric reinforcement are manifold. First and foremost, it significantly improves the tensile strength of concrete, enabling it to withstand greater loads and resist cracking under stress. This enhanced strength results in longer-lasting structures that require less maintenance over time.

Moreover, WWM is easier and quicker to install compared to traditional reinforcement methods. The prefabricated nature of welded wire mesh allows for rapid deployment on construction sites, thereby reducing labor costs. Once in place, the mesh provides a consistent and uniform reinforcement throughout the concrete, leading to better structural performance.

Cost-effectiveness is another major advantage. The use of welded wire fabric can reduce the amount of concrete needed for certain applications, which ultimately lowers material costs. Additionally, its durability means that structures reinforced with WWM are less likely to suffer from damage over time, reducing the need for costly repairs.

Considerations

While welded wire fabric offers numerous benefits, it is essential to consider factors such as load requirements, environmental conditions, and specific project needs when selecting the appropriate type of reinforcement. Consulting with structural engineers and construction professionals can help ensure that the correct specifications are chosen.

In conclusion, welded wire fabric reinforcement is a vital component in contemporary construction practices. Its strength, durability, and versatility make it an indispensable choice for a wide range of applications, from residential buildings to industrial projects. As the construction industry continues to evolve, the use of welded wire mesh will likely play an increasingly prominent role in enhancing structural integrity and ensuring the longevity of engineered structures.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025