- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Welded Metal Mesh Applications and Benefits in Modern Construction and Industry

Welded Metal Mesh Versatile Solutions for Industrial and Commercial Applications

Welded metal mesh is a versatile and robust product widely used across various industries for its strength, adaptability, and ease of installation. Made by welding together intersecting wires at their junctions, this type of mesh offers significant advantages over other forms of fencing and barrier solutions.

One of the primary materials used in the production of welded metal mesh is steel, which provides excellent strength and durability. Galvanized steel is often preferred due to its resistance to corrosion, making it suitable for outdoor applications. In recent years, stainless steel versions have also gained popularity in environments that require higher resistance to rust and degradation, such as in coastal areas or facilities that handle corrosive substances.

The manufacturing process of welded metal mesh involves using pre-cut wires that are arranged in a grid pattern and then welded together at their intersections. This results in a uniform mesh with consistent openings, allowing for various customization options regarding wire diameter, mesh size, and dimensions. Customizability is one of the reasons welded metal mesh is favored in industries that demand specific characteristics of the material, such as weight load capacity, openness, and aesthetic considerations.

One common application of welded metal mesh is in construction, where it is used for reinforcing concrete. The mesh provides tensile strength and stability, reducing the likelihood of cracking or structural failure. This reinforcement is particularly crucial in large structures like bridges, highways, and buildings. Additionally, welded metal mesh is integral to the production of wire fencing. It can serve as a barrier for livestock, keeping animals contained while simultaneously preventing the intrusion of predators. The robustness of welded wire fencing ensures longevity and low maintenance, making it an economical choice for farmers and ranchers.

Another significant application for welded metal mesh is in industrial environments, where it is utilized for safety barriers and machine guards

. The mesh can effectively contain machinery components and prevent accidental access to dangerous areas. In warehouses and production facilities, welded metal mesh can serve as partitions or shelving units, enhancing organization and safety while maximizing space utilization.welded metal mesh

In the realm of architecture, designers have increasingly begun to incorporate welded metal mesh into aesthetic elements of buildings. From facades to railing systems, the versatility of the mesh offers numerous possibilities in both functionality and appearance. Its ability to allow light to filter through while providing necessary structural support makes it an attractive option for modern architectural designs.

Welded metal mesh is also prevalent in the agriculture sector, where it is used for various purposes, including soil erosion control, plant support, and pest deterrence. Its ability to be shaped and cut into specific sizes makes it ideal for greenhouse applications and garden trellises, where plants can climb and flourish.

The ease of installation is another factor contributing to the popularity of welded metal mesh. The uniformity of the panels allows for quick assembly and integration into existing structures, saving time and labor costs in both residential and commercial projects. Furthermore, different finishes and coatings are available that enhance the mesh's resistance to environmental factors, ensuring it remains functional and aesthetically pleasing over time.

As sustainability becomes a more significant focus in the manufacturing and construction industries, welded metal mesh holds promise due to its recyclability. When no longer needed, it can be repurposed or recycled, reducing waste and environmental impact.

In conclusion, welded metal mesh is a durable, flexible, and sustainable solution suitable for various applications across multiple industries. Its strength, ease of installation, and versatility make it an ideal choice for construction, agriculture, industrial environments, and innovative architectural designs. As industries continue to evolve, the demand for welded metal mesh is expected to grow, further establishing its position as a fundamental element in modern infrastructure and safety.

share:

-

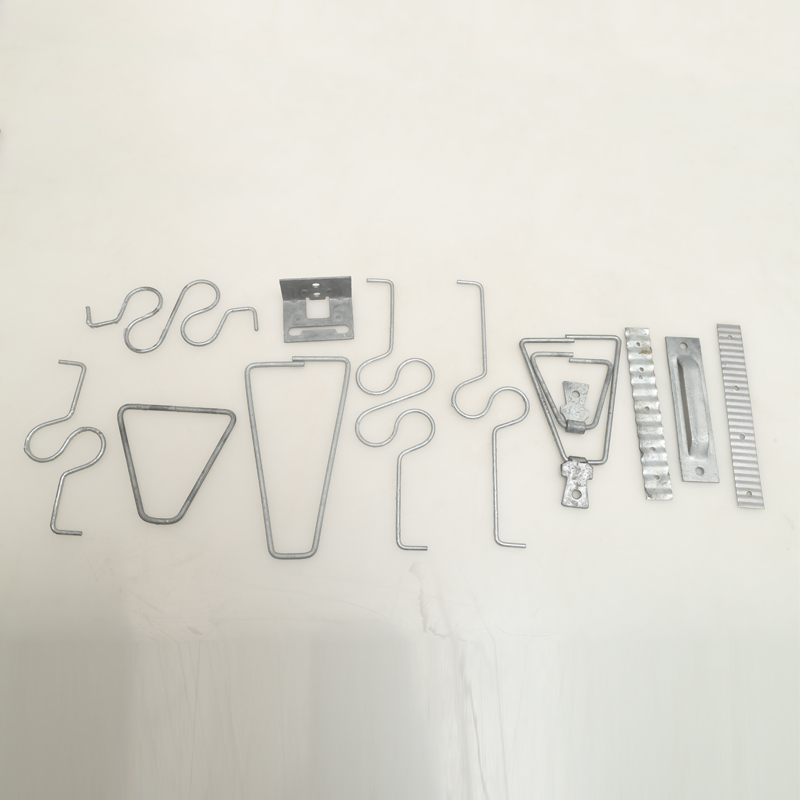

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025