- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

welded mesh formwork

Understanding Welded Mesh Formwork A Game Changer in Construction

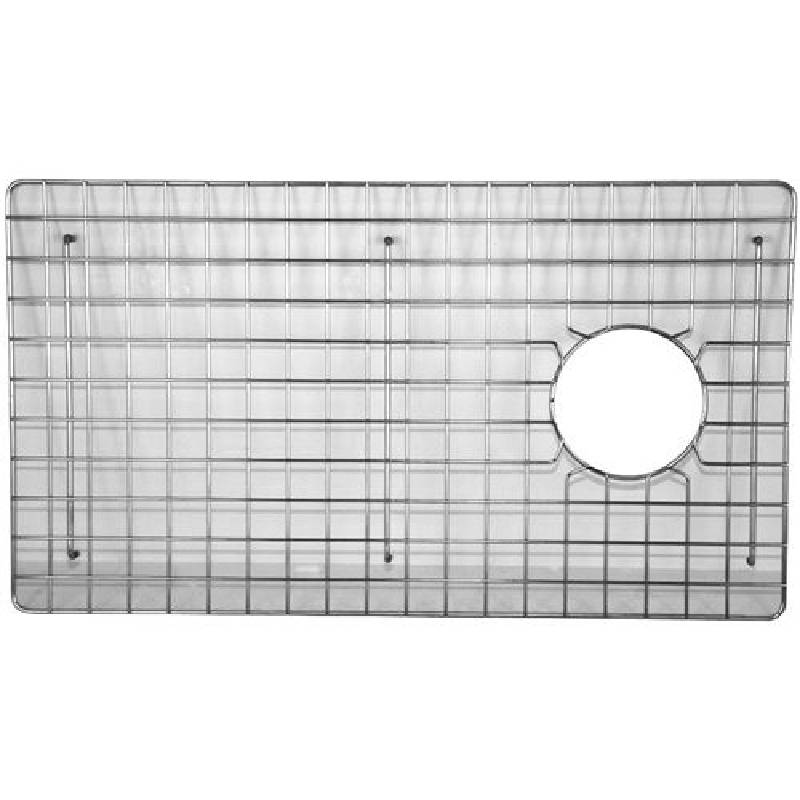

Welded mesh formwork has emerged as an innovative solution in the realm of construction, transforming traditional methodologies and enhancing overall efficiency. This form of formwork utilizes steel mesh that has been welded to create a robust framework, which serves as a mold for pouring concrete. Due to its unique design and structural advantages, welded mesh formwork has gained immense popularity in various construction projects, ranging from residential buildings to large industrial infrastructures.

One of the most significant benefits of welded mesh formwork is its strength and durability. The welded mesh is typically manufactured from high-quality steel, which provides a high load-bearing capacity and resistance to deformation. This robustness ensures that the formwork can withstand the pressure of wet concrete during the pouring process, reducing the risk of collapse and ensuring the safety of workers on site. Furthermore, the use of high-grade materials significantly prolongs the lifespan of the formwork, allowing for reuse across multiple projects, thereby offering an eco-friendly alternative to traditional timber formwork.

Another advantage of welded mesh formwork is its labor-saving efficiency. Traditional formwork systems often require extensive assembly and disassembly, consuming considerable time and resources. In contrast, welded mesh systems can be prefabricated to specific dimensions, allowing for quicker installation on-site. The lightweight nature of the welded mesh also contributes to easier handling and maneuverability, leading to reduced labor costs. Consequently, construction timelines can be significantly shortened, enabling projects to be completed more quickly without compromising on quality.

welded mesh formwork

Additionally, welded mesh formwork provides excellent concrete finishing quality. The smooth surface of the welded mesh facilitates a consistent distribution of concrete, resulting in superior surface finishes that minimize the need for further treatment. The elimination of protruding nails or wood pieces typically found in traditional formwork systems translates into a more aesthetically pleasing final product. This feature is particularly advantageous for architectural projects where visual appeal is a critical factor.

Moreover, welded mesh formwork is adaptable to various construction designs and applications. Whether constructing walls, slabs, or columns, the versatility of welded mesh allows builders to customize the formwork to suit specific project requirements. The mesh can be easily cut to size, bent, or shaped to accommodate complex designs, making it an ideal choice for both conventional and innovative architectural solutions.

Safety is another paramount consideration in the construction industry. Welded mesh formwork enhances safety on construction sites as it minimizes the risks associated with the use of traditional formwork methods. The stability and strength of the welded mesh reduce the likelihood of formwork failure, which can lead to accidents and injuries. Additionally, the streamlined installation process reduces the time workers spend on potentially hazardous tasks, contributing to a safer work environment.

In conclusion, welded mesh formwork represents a significant advancement in construction techniques, offering numerous advantages such as strength, efficiency, quality finishing, adaptability, and improved safety. As the industry continues to evolve and seek smarter technologies and materials, welded mesh formwork is well-positioned to play a crucial role in shaping the future of construction. By providing a reliable and cost-effective alternative to conventional methods, it not only streamlines the building process but also meets the growing demand for sustainable construction practices. As more builders recognize its benefits, the use of welded mesh formwork is expected to rise, paving the way for more innovative and efficient construction solutions.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025