- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

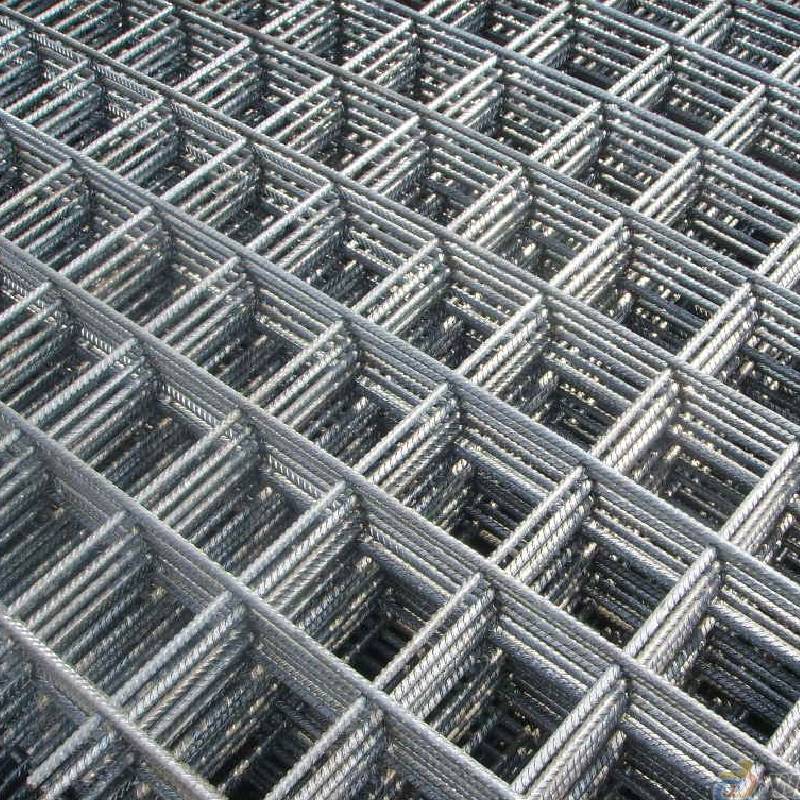

wall ties in cavity walls

Understanding Wall Ties in Cavity Walls

Cavity walls have been a popular construction choice in modern building practices, offering both structural integrity and thermal insulation. One of the essential components of cavity walls is wall ties, which play a crucial role in ensuring the stability and overall performance of the wall assembly. This article will delve into the function, types, and installation of wall ties in cavity walls, as well as their importance in preventing structural failure.

What Are Cavity Walls?

Cavity walls consist of two separate masonry walls, known as the 'inner' and 'outer' walls, with a ventilated space or cavity in between them. This cavity serves multiple purposes it provides insulation, reduces heat loss, and allows for moisture drainage. Cavity walls are especially beneficial in climates where water ingress is a concern, as they can effectively shed rainwater and moisture.

The Role of Wall Ties

Wall ties are essential components that connect the inner and outer walls of cavity walls, providing support and stability. They allow for the two walls to act as a single unit, helping to resist lateral forces that might cause the walls to lean or separate. In addition to structural support, wall ties also help monitor the movement between the inner and outer walls, reducing the risk of cracking or other types of damage.

Types of Wall Ties

Wall ties come in various materials and designs, suitable for different construction types and environmental conditions. The most common materials include stainless steel, galvanized steel, and plastic. Each material has its own advantages

1. Stainless Steel Highly corrosion-resistant and suitable for both residential and commercial buildings. Stainless steel ties have a long lifespan and are ideal for coastal regions where salty air may accelerate corrosion.

2. Galvanized Steel Coated with zinc to enhance corrosion resistance. They are cost-effective and widely used but may have a shorter lifespan than stainless steel in harsher environments.

wall ties in cavity walls

3. Plastic Wall Ties Lightweight and resistant to corrosion, plastic wall ties are increasingly used in modern construction due to their ease of installation and minimal thermal conductivity.

Installation and Spacing of Wall Ties

Proper installation of wall ties is crucial to ensure their effectiveness. Building standards recommend that wall ties are correctly spaced and aligned during construction. The typical spacing for wall ties in cavity walls depends on the wall height and the type of materials used, but a common guideline is to place ties at intervals of no more than 600 mm vertically and 900 mm horizontally.

Wall ties should be installed at an angle to facilitate the drainage of moisture from the cavity and to minimize the risk of corrosion. The ties must be embedded sufficiently into both the inner and outer walls, usually requiring a minimum embedment of 50 mm to ensure adequate bond strength.

Importance of Wall Ties

The significance of wall ties cannot be overstated. They provide essential support to cavity wall systems, contributing to the overall safety and durability of buildings. Insufficient or poorly installed wall ties can lead to several issues, such as bowing walls, cracking, or even complete structural failure.

Moreover, wall ties play a pivotal role in moisture control. They help ensure that any trapped moisture within the cavity can drain effectively, thus preventing mold growth, deterioration of building materials, and deterioration of thermal insulation.

Conclusion

In summary, wall ties are a critical component of cavity walls that contribute to structural stability and moisture management. By connecting the inner and outer walls, they ensure the building's integrity while facilitating proper drainage. Understanding the types, installation practices, and importance of wall ties can help construction professionals make informed decisions, ultimately leading to safer, more durable structures. Proper consideration of these elements ensures that cavity walls perform effectively, standing the test of time and environmental challenges.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025