- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

200mm Wall Ties for Enhanced Structural Stability and Durability in Construction Projects

Understanding Wall Ties The Importance of 200mm Specifications

In the realm of construction and building, the details often make the difference between a long-lasting structure and one that faces issues down the line. One such detail that plays a crucial role in masonry construction is the wall tie. Among the various specifications and sizes available, the 200mm wall tie stands out for its specific benefits and applications. This article explores the significance, materials, installation practices, and advantages of 200mm wall ties in masonry work.

What Are Wall Ties?

Wall ties are critical components used in the construction of cavity walls and brickwork. Their primary function is to connect two layers of masonry together, which helps maintain the structural integrity of a building. Wall ties prevent the walls from moving apart due to lateral forces, and they also provide stability in case of environmental stressors like wind or seismic activity. This is particularly important in regions prone to harsh weather conditions.

The Significance of 200mm Wall Ties

The 200mm specification refers to the length of the wall tie. This particular size is often used in situations where a standard tie may be too short, especially in thicker cavity wall constructions. The 200mm wall tie is versatile, allowing builders to ensure proper engagement with both the inner and outer leaves of masonry. Proper engagement is crucial for providing stability and transferring loads effectively throughout the structure.

Using a 200mm wall tie can also be a matter of compliance with building codes and regulations. Many construction guidelines specify minimum sizes and spacing for wall ties, and a 200mm tie often meets these requirements, ensuring safety and durability.

Materials Used in Wall Ties

Wall ties are made from various materials, each with unique properties. The most common materials include

1. Stainless Steel Known for its corrosion resistance, stainless steel wall ties are ideal for exposed applications and areas with high humidity. They are robust and can be expected to last the lifetime of the structure.

2. Galvanized Steel This is a cost-effective alternative that offers a fair degree of corrosion protection due to the zinc coating. Galvanized steel wall ties are commonly used in standard construction applications.

3. Plastic Although not as prevalent as metal wall ties, plastic ties are lightweight and resistant to corrosion. They are often used in specialized scenarios where metal ties may pose a risk, such as in sensitive or corrosive environments.

4. Fiber Reinforced Polymer (FRP) This is a newer material that has gained popularity for its high strength-to-weight ratio and excellent resistance to corrosion. FRP wall ties are increasingly being used in advanced construction projects.

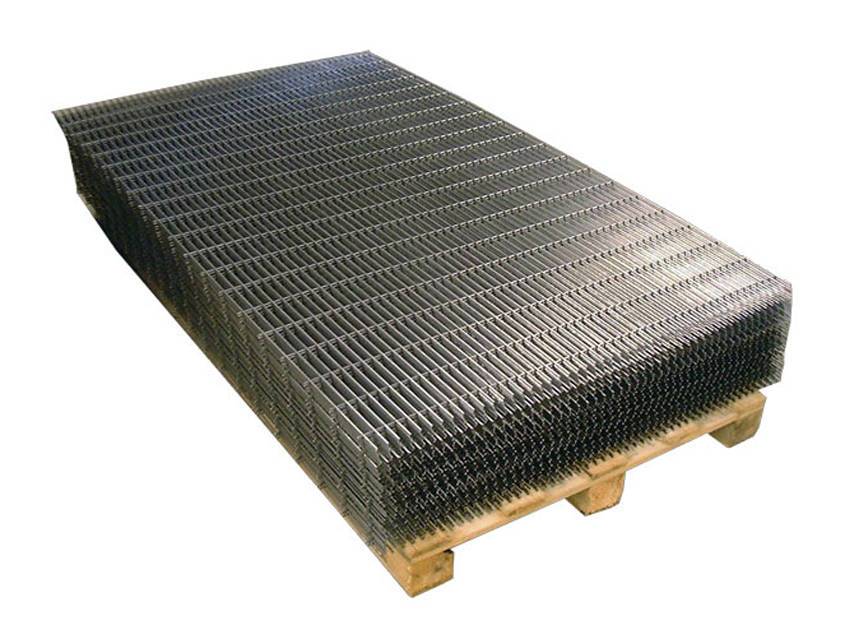

wall ties 200mm

Installation Practices

The installation of wall ties is a crucial step in ensuring the safety and longevity of a building. Proper positioning and spacing are essential for optimal performance. For 200mm wall ties, builders typically adhere to the following practices

- Spacing Wall ties should be spaced appropriately, usually at intervals specified by building codes—typically around 600mm vertically and 900mm horizontally. This ensures a consistent bond between the masonry layers.

- Placement Wall ties should be embedded in the mortar of both the inner and outer walls. The 200mm length allows for maximum engagement and stability, properly anchoring both layers.

- Alignment Ensuring that ties are level and aligned is critical to avoid placing undue stress on the wall assembly. Misalignments can lead to structural weaknesses over time.

Advantages of Using 200mm Wall Ties

Utilizing 200mm wall ties in construction projects offers several advantages

1. Improved Stability The longer length provides better anchoring and reduced movement between masonry layers, enhancing overall stability.

2. Versatility These wall ties can be used in various building types, including residential and commercial structures, making them a versatile choice.

3. Compliance and Safety Meeting building codes with appropriately sized wall ties ensures that the construction adheres to safety standards.

4. Longevity Properly installed wall ties, regardless of material, contribute significantly to the durability of masonry walls, reducing the likelihood of costly repairs down the line.

In conclusion, 200mm wall ties play an indispensable role in modern masonry work. Understanding their significance, selecting the right materials, and employing best practices during installation are crucial steps that builders must take to ensure structural integrity and longevity. As technology and materials continue to evolve, wall ties, particularly those measuring 200mm, will remain an essential component in the construction industry.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025