- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

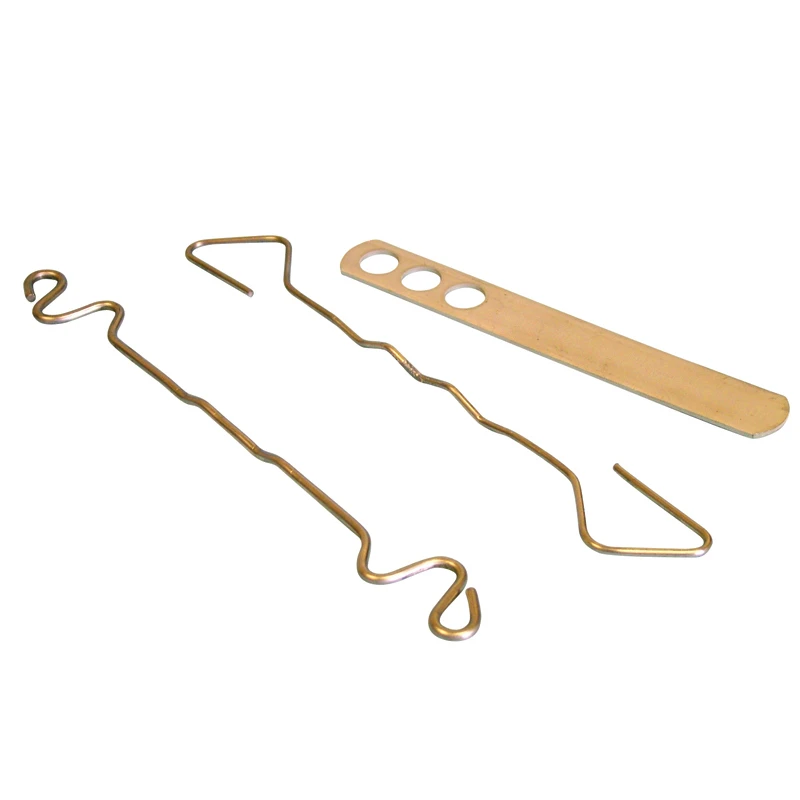

v shaped torsion springs

Understanding V-Shaped Torsion Springs Design, Applications, and Benefits

V-shaped torsion springs are a crucial component in various mechanical systems, offering reliable performance and efficient design. These unique springs are characterized by their distinct V-shape, allowing them to store energy and apply torque in a compact form. In this article, we explore the design, applications, and advantages of V-shaped torsion springs.

Design and Functionality

V-shaped torsion springs operate based on the principle of torsion, which involves twisting the spring along its axis to store mechanical energy. When a force is applied to the ends of the spring, it deforms, creating potential energy that can be released when the force is removed. The V-shape is not just a stylistic choice; it provides enhanced stability and increased resistance to buckling compared to traditional cylindrical torsion springs. This design allows for a more compact spring while maintaining functionality, making V-shaped torsion springs ideal for applications with limited space.

The manufacturing process of these springs typically involves high-carbon steels or stainless steels, which provide high tensile strength and flexibility. These materials ensure that the spring can withstand repeated cycles of loading and unloading without losing its integrity.

Applications

V-shaped torsion springs are widely used across various industries due to their versatility. Some of the common applications include

1. Automotive Industry In vehicles, these springs are often used in mechanisms such as tailgates, hoods, and various latch assemblies. They provide the necessary tension to keep parts in place and ensure smooth operation.

2. Industrial Machinery V-shaped torsion springs are used in the assembly of conveyor systems, packaging machines, and other manufacturing equipment. Their ability to withstand heavy loads while allowing for smooth movements makes them indispensable in these applications.

3. Furniture Many types of furniture, particularly recliners and office chairs, employ V-shaped torsion springs to enable reclining mechanisms and adjustability. Their compact design allows them to fit seamlessly within the frame of the furniture.

v shaped torsion springs

4. Consumer Appliances Everyday appliances, such as washing machines and dishwashers, utilize V-shaped torsion springs in their door mechanisms. The springs provide the necessary force to keep the doors securely closed during operation.

Advantages

The advantages of opting for V-shaped torsion springs over other types of springs are numerous

- Space Efficiency The V-shape allows for a more compact design, making it possible to use them in applications where space is at a premium.

- Enhanced Stability The shape provides greater stability and resistance to buckling, which is critical in high-stress applications.

- Versatile Design V-shaped torsion springs can be designed in various sizes and strengths, accommodating a wide range of load requirements.

- Durability Made from high-quality materials, these springs offer longevity and resilience against wear and fatigue.

Conclusion

V-shaped torsion springs play an integral role in modern engineering and manufacturing. Their unique design, coupled with the ability to provide effective torque and stability, makes them an ideal choice for numerous applications across multiple industries. As technology advances, the demand for efficient and reliable mechanical components like V-shaped torsion springs will continue to rise, reinforcing their importance in today’s mechanical landscape. Understanding their design, functionality, and applications enables engineers and manufacturers to leverage their benefits effectively, leading to improved product performance and efficiency.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025