- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Understanding the Benefits and Applications of Utility Springs in Various Industries

Understanding Utility Springs Their Importance and Applications

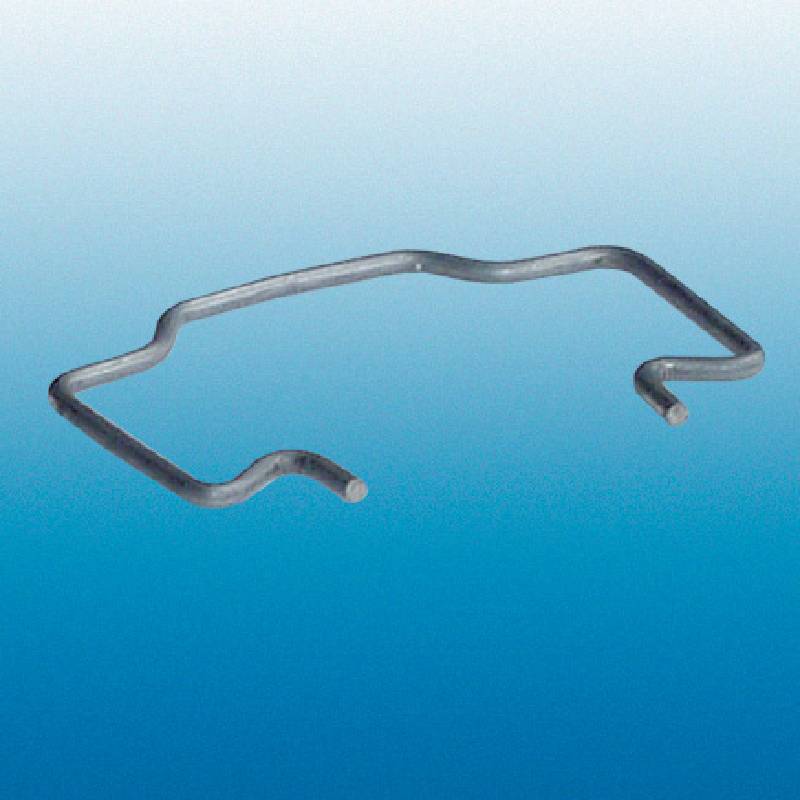

Utility springs, commonly known as compression or extension springs, are essential components in various mechanical systems. Though they may seem like simple coils of metal, their applications and importance are vast and significant across multiple industries. This article aims to explore the characteristics, applications, and significance of utility springs in mechanical design and everyday life.

What Are Utility Springs?

Utility springs are mechanical devices that store and release energy when a force is applied to them. Typically made from high-carbon steel or stainless steel, they can be designed in various shapes and sizes to fit specific requirements. There are primarily two types of utility springs compression springs, which are designed to resist compressive forces, and extension springs, which are designed to handle tension.

The design of utility springs involves various parameters, including wire diameter, coil diameter, and the number of active coils, all of which contribute to the spring's stiffness and load-bearing capacity. These factors are crucial because they determine how much force the spring can exert and how much deformations it can withstand.

Applications of Utility Springs

Utility springs are found in numerous applications, making them indispensable in various fields

1. Automotive Industry In automobiles, utility springs play a critical role in suspension systems. They absorb shocks from the road, ensuring a smooth ride and improving vehicle handling. Additionally, they are used in numerous other components, including clutch mechanisms, brake systems, and hoods.

2. Consumer Electronics Springs are used in electronic devices to provide tactile feedback or ensure that components return to their neutral position after being pressed. For example, utility springs can be found in keyboards, mice, and various handheld devices.

utility springs

3. Home Appliances From washing machines to refrigerators, utility springs are utilized to enhance functionality. They help in balancing weight, absorbing vibrations, and ensuring smooth operation of various mechanisms within appliances.

4. Aerospace Applications In the aerospace industry, where reliability and performance are critical, utility springs are crucial in various applications, including landing gear and control systems. They help absorb shocks during landing and provide necessary tension in control surfaces.

5. Medical Devices Utility springs are integral to many medical devices, including blood pressure cuffs and various diagnostic tools. Their ability to provide precise resistance and return to their original shape makes them vital in applications requiring accuracy and dependability.

The Importance of Utility Springs

The significance of utility springs extends beyond their physical properties. They are critical in ensuring the durability, efficiency, and reliability of countless products. The ability of a spring to absorb and release energy makes it a fundamental element in reducing wear and tear on mechanical components, thus prolonging the lifespan of devices and systems.

Moreover, the design and manufacturing processes of utility springs have evolved significantly. Advanced materials and computer-aided design (CAD) technologies enable engineers to create springs with specific tolerances and performance characteristics, leading to improved functionality and efficiency in applications.

Conclusion

In summary, utility springs may seem like minor components in the grand design of machinery and devices, but their role is anything but trivial. They are the backbone of many mechanical systems, providing essential functionalities that enhance user experience and product performance. As technology continues to evolve, the importance of utility springs will only increase, driving further innovation in their design and applications. Understanding their significance helps us appreciate the intricate engineering that underlies the products we use daily, highlighting how seemingly simple components can have a profound impact on functionality and efficiency across an array of industries.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025