- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Understanding Different Types of Spring Hooks for Extensions in Software Development

Understanding Extension Spring Hook Types An Overview

Extension springs are a crucial component in various mechanical systems, providing essential tensioning and support. These springs are designed to absorb energy and return it to the users in a controlled manner. A significant aspect of extension springs is their hooking mechanism, which allows them to be anchored or connected to other components. In this article, we'll explore the different types of hooks associated with extension springs, their functions, and applications.

Types of Extension Spring Hooks

1. Machine Hooks Machine hooks are among the most common types used in extension springs. Their design typically consists of a simple loop that is attached to the end of the spring. They are effective in applications that require minimal load-bearing capacity and where the spring must be easily connected or disconnected. Machine hooks are ideal for consumer products, such as toys and household appliances.

2. Straight Hooks Straight hooks feature a linear design that extends from the end of the spring. These hooks are often used in scenarios where alignment is critical and the load is relatively consistent. Straight hooks are well-suited for applications involving cable systems or tension applications in machinery. They provide a robust connection point, ensuring that the extension spring functions effectively without slipping.

3. Double Hooks As the name suggests, double hooks incorporate two hooks on each end of the spring. This design offers increased versatility and allows for improved load distribution, making them suitable for applications requiring high tension and stability. Double hooks are prevalent in industrial machinery, automotive applications, and various equipment where balanced force is essential for operation.

4. European Hooks Named for their European origin, these hooks possess a unique design that provides additional security. European hooks often have a pronounced curve and are designed to lock into a corresponding attachment point, minimizing the risk of detachment during operation. Their reliable performance makes them an excellent choice for applications in transportation, construction, and industrial equipment.

5. Custom Hooks Many manufacturers offer the option to create custom hooks tailored to specific application needs. These custom hooks can be adjusted in shape, size, and flexibility based on the requirements of a particular project. Custom hooks are particularly valuable in specialized machinery or complex assemblies, where standard options may not provide the necessary performance.

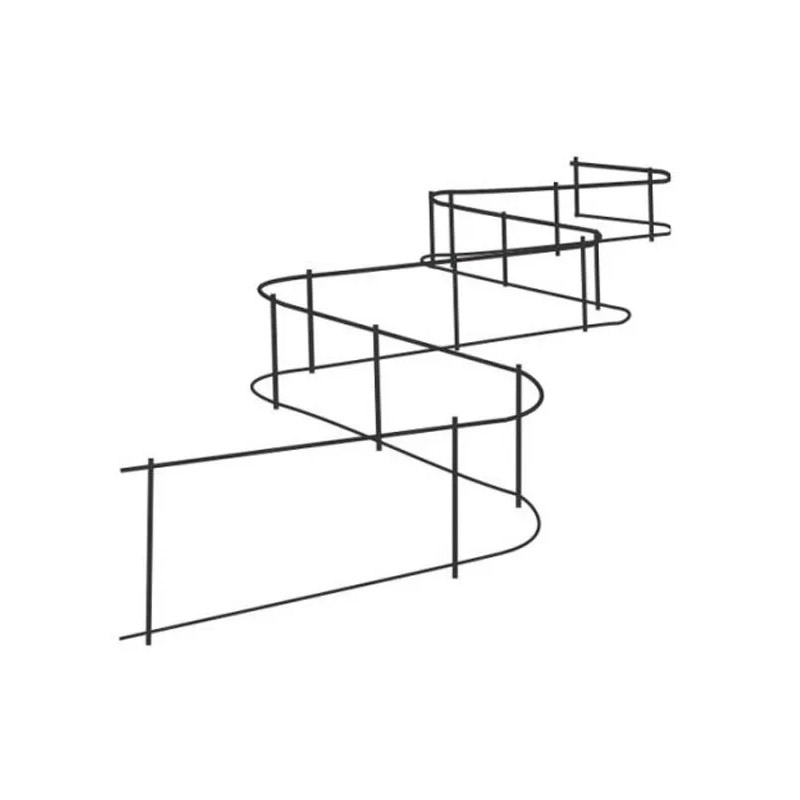

extension spring hook types

Applications of Extension Spring Hooks

Extension spring hooks are widely used across various industries, from manufacturing to aerospace. They play a vital role in applications requiring tension and flexibility, such as

- Automotive Extension springs facilitate the operation of various components in vehicles, including hoods, trunks, and seat mechanisms

.- Furniture In furniture manufacturing, extension springs maintain tension in folding tables and chairs, allowing for smooth and reliable operation.

- Industrial Equipment Many machines utilize extension springs with specialized hooks to manage tension and ensure proper functionality in production lines and automated systems.

- Aerospace Extension springs are also employed in aircraft mechanisms where precision and reliability are paramount.

Conclusion

Understanding the different types of hooks associated with extension springs is essential for selecting the right component for your application. From machine hooks to double and custom hooks, each type offers unique benefits and fits various uses across multiple industries. When designing or maintaining equipment that utilizes extension springs, considering the hook type can greatly impact efficiency, safety, and reliability in operation. As technology evolves, so will the designs and functionalities of extension spring hooks, continuing to enhance their vital role in modern mechanical systems.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025