- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

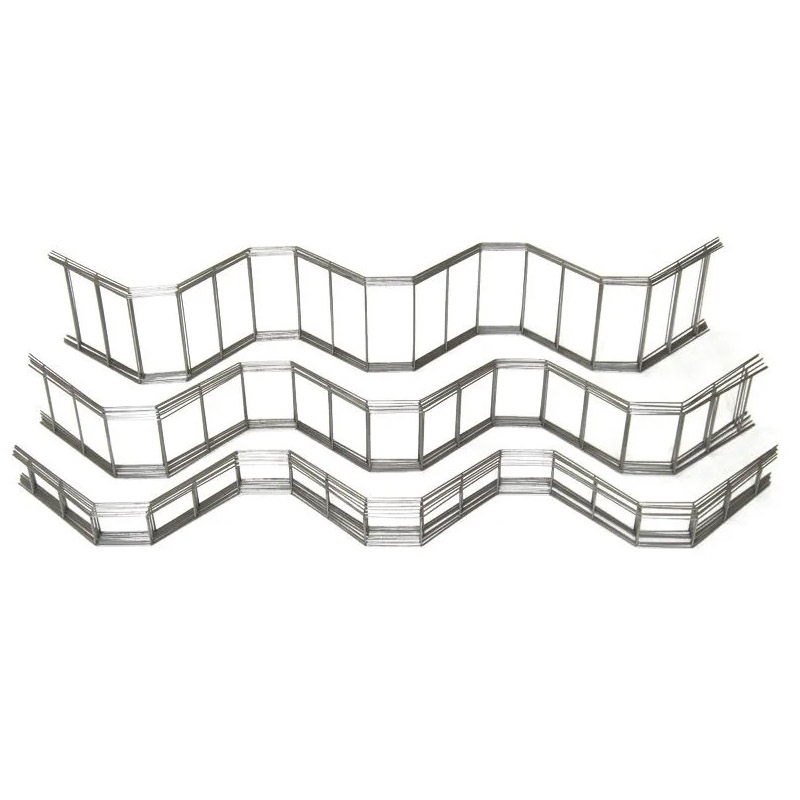

titanium compression springs

The Significance of Titanium Compression Springs in Modern Engineering

In the realm of engineering and manufacturing, springs play a vital role in the functionality and durability of countless mechanical systems. Among various types of springs, titanium compression springs have gained significant attention due to their unique properties and advantages, making them a preferred choice in a variety of applications. This article explores the characteristics, benefits, and applications of titanium compression springs, illustrating their importance in modern engineering.

Understanding Compression Springs

Compression springs are designed to resist compressive force and return to their original shape when the load is removed. They are typically made from coiled wire and are used in mechanisms that require force to be exerted when compressed. The design and material of the spring are crucial in determining its performance characteristics, such as stiffness, durability, and resistance to fatigue.

The Advantages of Titanium

Titanium, a lightweight yet robust metal, is increasingly being used as a material for compression springs. The most relevant properties of titanium that enhance the performance of compression springs include

1. High Strength-to-Weight Ratio Titanium possesses a remarkable strength-to-weight ratio, making it an ideal material for applications where reducing weight is critical without compromising strength. This is particularly important in aerospace and automotive sectors.

2. Corrosion Resistance Titanium exhibits exceptional resistance to corrosion, making it suitable for use in harsh environments, including marine applications or areas where exposure to chemicals is common. This property significantly extends the lifespan of compression springs made from titanium.

3. Fatigue Resistance Titanium springs can endure repeated loading and unloading cycles without significant degradation in performance. This fatigue resistance is essential for applications that experience continuous stress.

4. Biocompatibility As titanium is biocompatible, it finds applications in the medical field, particularly in prosthetics and implants. This ensures that titanium compression springs can be safely inserted into the human body without causing adverse reactions.

titanium compression springs

Applications of Titanium Compression Springs

The advantageous properties of titanium compression springs make them suitable for a diverse range of applications

1. Aerospace Engineering The aerospace industry demands lightweight materials that provide maximum strength and durability. Titanium compression springs are used in aircraft systems, including landing gear, control mechanisms, and engine components, where reliability is paramount.

2. Automotive Industry In the automotive sector, these springs are utilized in suspension systems, where they help absorb shocks and vibrations. Their lightweight nature contributes to improved fuel efficiency and performance.

3. Medical Devices In the medical field, titanium compression springs are used in various devices, such as surgical instruments and implants. Their biocompatibility and corrosion resistance are essential for ensuring safety and longevity.

4. Industrial Machinery Many industrial machines rely on compression springs to maintain tension and provide shock absorption. The use of titanium springs in these settings enhances the overall durability and effectiveness of the machinery.

5. Consumer Electronics With the increasing miniaturization of electronic devices, titanium compression springs are employed in various consumer products, including smartphones and laptops, to ensure reliability and performance in compact spaces.

Conclusion

Titanium compression springs represent a significant innovation in the design and implementation of spring technology. Their unique combination of lightweight strength, corrosion resistance, fatigue endurance, and biocompatibility makes them an unparalleled choice across various industries. The ongoing advancements in titanium material science and manufacturing processes promise even greater applications in the future, solidifying titanium compression springs as an essential component in modern engineering.

In summary, the shift towards more advanced materials like titanium demonstrates the industry's commitment to optimizing performance, longevity, and efficiency. As technology continues to evolve, titanium compression springs will remain at the forefront of engineering solutions, supporting innovations that enhance our daily lives. Whether in critical aerospace applications, demanding medical environments, or everyday consumer products, the significance of titanium compression springs cannot be overstated.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025