- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

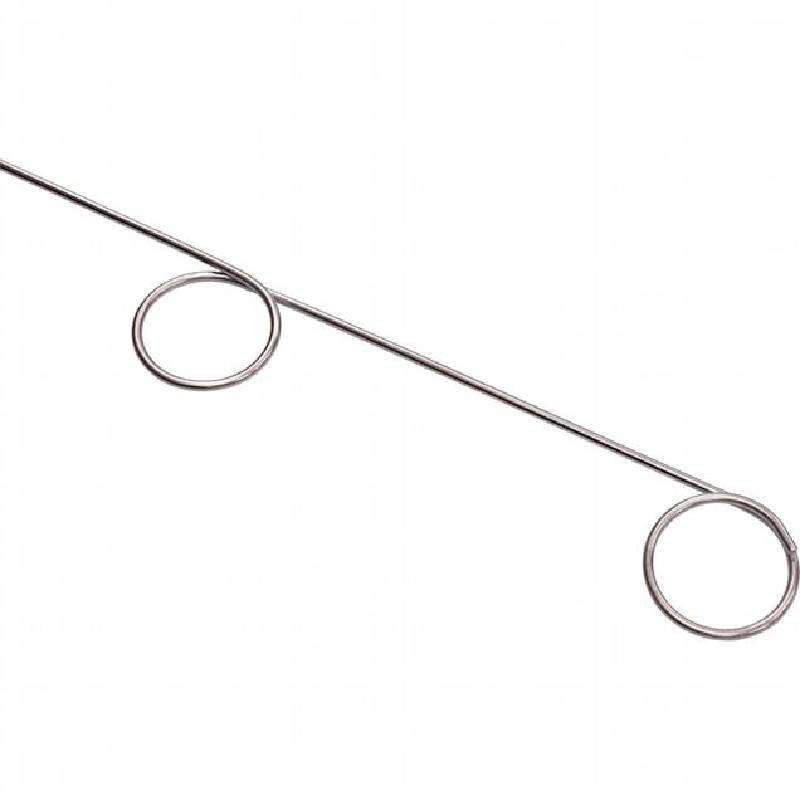

titanium coil spring

Understanding Titanium Coil Springs The Future of Engineering

In the realm of engineering and design, the material selection is one of the most critical aspects that can profoundly influence the performance and longevity of mechanical components. Among the plethora of materials available, titanium has emerged as a standout choice, particularly in the manufacturing of coil springs. This article delves into the innovative world of titanium coil springs, exploring their benefits, applications, and the reasons they are becoming increasingly popular in various industries.

What are Titanium Coil Springs?

Coil springs are mechanical devices that store and release energy, typically made from steel or other alloys. Titanium coil springs, however, utilize titanium, a lightweight, high-strength metal known for its excellent corrosion resistance and fatigue properties. These springs are designed to compress and expand, providing support and absorbing shocks in a variety of applications, making them essential in automotive, aerospace, and industrial machinery.

Advantages of Titanium Coil Springs

1. Lightweight One of the most significant advantages of titanium is its weight. Titanium coil springs are considerably lighter than their steel counterparts. This reduction in weight translates to improved performance in applications where weight savings are critical, such as in aerospace and automotive designs. Less weight means better fuel efficiency and improved payload capacities.

2. Strength-to-Weight Ratio Titanium boasts an outstanding strength-to-weight ratio. This means that titanium coil springs can support higher loads while maintaining lighter weights, making them an ideal choice for high-performance applications that demand both strength and efficiency.

3. Corrosion Resistance Titanium is naturally resistant to a wide range of chemicals and environmental factors, making it less prone to rust and corrosion. This property is especially beneficial in marine and chemical processing industries, where components are exposed to harsh environments.

4. Fatigue Resistance The fatigue life of titanium is superior to that of many traditional materials. This means that titanium coil springs can withstand repeated stress cycles without deforming or breaking, contributing to a longer lifespan and decreased maintenance needs.

titanium coil spring

5. Thermal Stability Titanium maintains its mechanical properties at high temperatures, making it suitable for applications involving heat, such as in the automotive and aerospace sectors. It remains stable, retaining its strength and spring characteristics even in challenging thermal environments.

Applications of Titanium Coil Springs

1. Aerospace The aerospace industry is one of the primary beneficiaries of titanium coil springs. With stringent weight reduction goals and high-performance requirements, manufacturers are turning to titanium springs for landing gear mechanisms, actuators, and flight control systems.

2. Automotive In automotive applications, reducing weight while enhancing performance is paramount. Titanium coil springs are increasingly used in suspension systems, offering improved handling and stability, as well as contributing to overall vehicle performance.

3. Medical Devices Titanium's biocompatibility makes it an attractive option for biomedical applications. Titanium coil springs are used in various medical devices, including implants and surgical instruments, ensuring durability and reliability.

4. Industrial Machinery In various industrial settings, titanium coil springs provide reliable performance in demanding conditions. Their resistance to corrosion and fatigue makes them ideal for machinery in chemical processing, oil and gas, and manufacturing industries.

Conclusion

Titanium coil springs represent a remarkable advancement in materials science and engineering, offering a combination of lightweight, strength, and corrosion resistance that is hard to match. As industries continue to seek innovative solutions for enhancing performance and efficiency, titanium springs are slated to play a crucial role. With their wide-ranging applications—from aerospace to medical devices—titanium coil springs are not just a trend but a key component of the future of technology and mechanics.

As manufacturers and engineers continue to explore the benefits of titanium, it's clear that the future holds even more potential for this versatile material. Embracing titanium coil springs can lead to groundbreaking innovations that push the boundaries of design and enhance the applications within which they are used, ultimately leading to a more efficient and resilient world of engineering.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025