- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

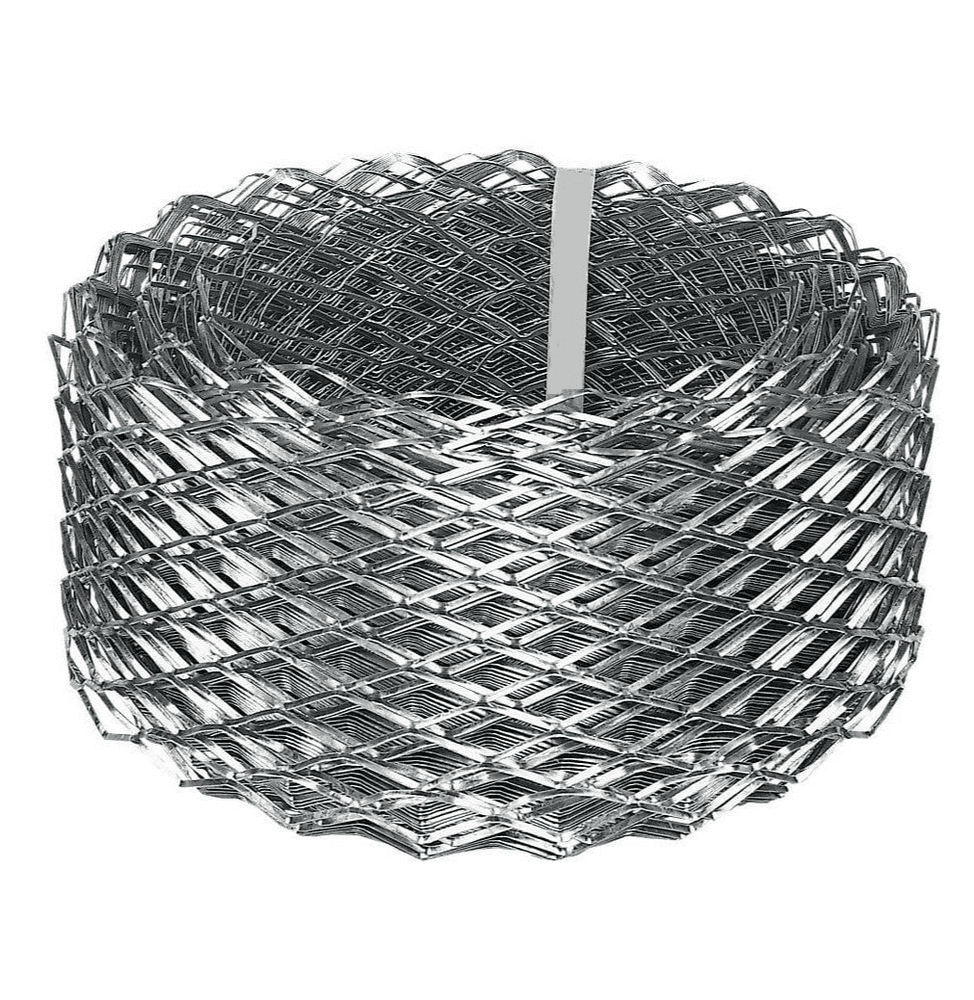

tension spring manufacturers

The Importance of Tension Springs and Their Manufacturers

Tension springs, essential components in a variety of applications, play a critical role in ensuring functionality and efficiency across numerous industries. These springs are designed to resist tensile forces; they stretch when a force is applied and return to their original shape once the force is removed. As a result, they are indispensable in mechanisms requiring a pull, helping to balance loads and provide necessary resistance.

The manufacturing of tension springs is a detailed process that requires precision engineering and high-quality materials. Manufacturers often utilize various types of steel, including music wire and stainless steel, to produce springs that can withstand diverse environments and stresses. The choice of material greatly influences the spring's performance, durability, and overall suitability for specific tasks.

One of the key factors in tension spring manufacturing is the production process, which requires advanced technology and skilled labor. Typically, manufacturers employ techniques such as coiling, tempering, and plating. These processes ensure that the springs not only meet functional specifications but also have the longevity needed to withstand repetitive loading. For instance, a properly tempered tension spring can endure countless cycles without losing its structural integrity.

tension spring manufacturers

Tension spring manufacturers also face several challenges, including customizing springs to fit unique applications. Many industries, from automotive to aerospace and electronics, demand springs that are tailored for specific dimensions, tensile strength, and durability requirements. Leading manufacturers invest in research and development to innovate solutions that meet these challenges, often collaborating closely with clients during the design phase to deliver optimal products.

Quality assurance is another critical aspect of the manufacturing process. Leading manufacturers implement stringent quality control measures to ensure that the tension springs produced meet industry standards and customer expectations. This often involves rigorous testing methods, including fatigue testing and load testing, to confirm that the springs perform reliably under intended conditions.

As the demand for tension springs continues to grow, particularly in the context of advanced manufacturing and smart technology, the role of skilled manufacturers becomes increasingly important

. They not only provide essential components but also contribute to advancements in engineering and design flexibility.In conclusion, tension springs are vital to the functionality of many mechanical systems, and the professionals who manufacture them are crucial to ensuring that these systems operate effectively. From carefully selecting materials to implementing strict quality control processes, tension spring manufacturers play a significant role in a wide range of industries. Their commitment to innovation and precision engineering not only enhances the performance of products but also supports the continuous advancement of technology in various fields. With their expertise, tension spring manufacturers are not just providers of components; they are integral partners in the growth and functionality of modern engineering solutions.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025