- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Tailored Coil Springs for Enhanced Performance in Various Applications and Industries for Optimal Support

Custom Coil Springs An Overview of Their Importance and Applications

Coil springs are essential components used in a wide variety of applications, from automotive engineering to industrial machinery and consumer products. Custom coil springs, in particular, are designed to meet specific requirements, providing tailored solutions for unique applications. This article explores the significance of custom coil springs, their manufacturing processes, and their diverse applications.

What Are Coil Springs?

Coil springs are helical springs made from durable materials, typically steel, that can store and release energy. They are designed to absorb shock, maintain tension, and provide support in applications where motion is involved. The design of a coil spring allows it to compress or extend, enabling it to bear loads and return to its original shape. This functionality is crucial across numerous industries, making coil springs indispensable in modern engineering.

The Importance of Customization

The need for custom coil springs arises when standard springs do not fulfill specific mechanical requirements. Customization can involve altering various design parameters, including diameter, wire thickness, coil count, and spring length. These adjustments ensure that the spring can withstand particular weights, resist specific conditions (such as temperature variations or corrosive environments), and fit precisely within a designed space.

Moreover, the customization process allows for the inclusion of special finishes or coatings, further enhancing the spring's longevity and performance. For instance, a custom coil spring used in a marine application may require a corrosion-resistant coating to withstand harsh saltwater conditions.

Manufacturing Process

The creation of custom coil springs typically involves several key steps

1. Design and Engineering The process begins with a thorough analysis of the requirements. Engineers use CAD (Computer-Aided Design) software to create detailed designs, allowing for precise specifications that meet the expected performance.

2. Material Selection Choosing the right material is critical. Common materials for coil springs include oil-tempered wire, music wire, and stainless steel, each offering unique properties in terms of strength, flexibility, and resistance to fatigue.

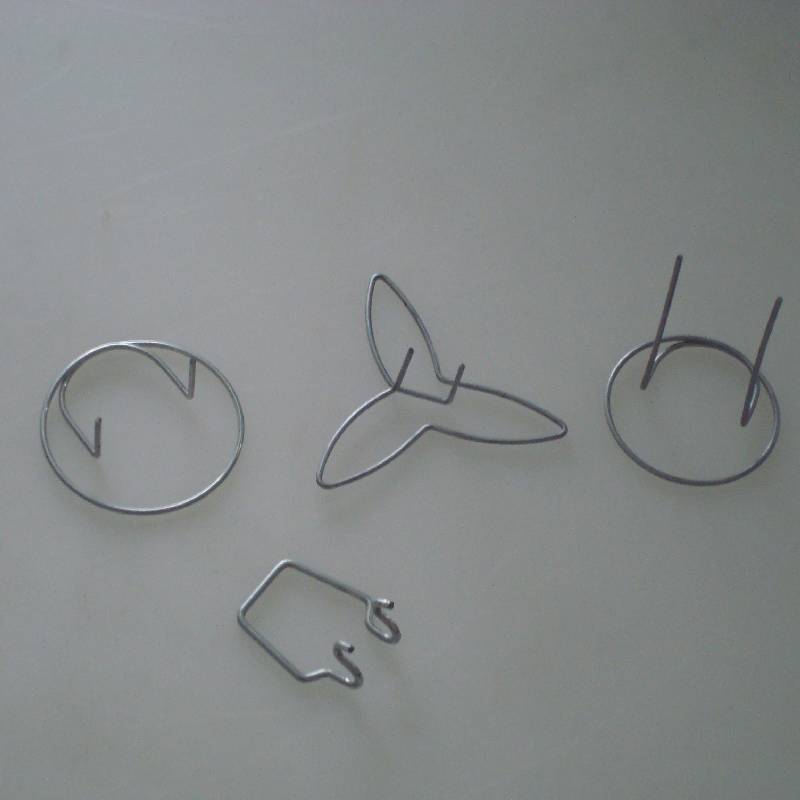

custom coil springs

3. Coiling The selected wire is then wound into a tight helix using specialized machinery. This step requires precise control to ensure the correct diameter and tension are achieved.

4. Heat Treatment After coiling, the springs are often heat-treated. This process enhances their mechanical properties, increasing strength and durability.

5. Finishing Touches Finally, the coils undergo finishing processes, which may include shot peening, coating, or grinding, ensuring they meet the precise requirements of their application.

Applications of Custom Coil Springs

Custom coil springs find applications in a wide range of industries

- Automotive In vehicles, custom coil springs are used for suspension systems, ensuring a smooth ride by absorbing shocks from the road.

- Aerospace They play a critical role in extensive aerospace applications, providing reliable performance in various components, including landing gear and control surfaces.

- Industrial Many machines rely on custom coil springs to maintain pressure, tension, and stability during operations.

- Consumer Products Custom coil springs are also found in everyday items, such as mattresses, household appliances, and fitness equipment, enhancing comfort and functionality.

Conclusion

Custom coil springs are vital in many industries, providing tailored solutions that enhance performance, longevity, and reliability. Their ability to be customized according to specific requirements makes them indispensable in applications where standard solutions are inadequate. As technology advances, the methods used in designing and manufacturing these springs continue to improve, driving innovation and efficiency across various sectors. Understanding the importance and functionality of custom coil springs is crucial for industries that rely on precise engineering and high-quality components.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025