- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Understanding Straight Torsion Springs and Their Applications in Mechanical Design

Understanding Straight Torsion Springs Design, Functionality, and Applications

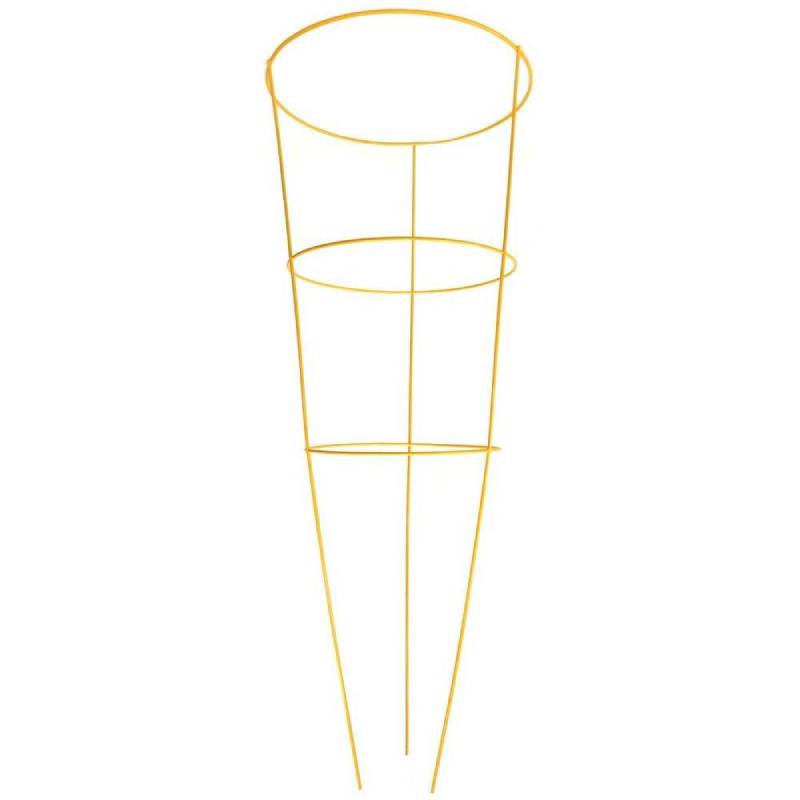

Straight torsion springs are mechanical devices designed to exert rotational force or torque when twisted. They differ from other types of springs, such as compression or extension springs, primarily in their functionality and application. The design of a straight torsion spring is characterized by its helical shape, which allows it to store and release energy through angular displacement rather than linear movement.

The basic principle of a torsion spring revolves around its ability to store potential energy when it is subjected to torque. When a force is applied to twist the arm of the spring, it undergoes angular deflection. This deflection results in the spring storing energy that can be released when the force is removed. The amount of torque generated by a torsion spring is determined by its material properties, geometry, and the degree of twist applied to it.

Materials used in the manufacturing of straight torsion springs typically include high-carbon steel, stainless steel, and other alloys known for their elasticity and strength

. The selection of material significantly affects the spring's performance, durability, and resistance to fatigue. For instance, high-carbon steel is commonly used for applications requiring high strength and resilience, while stainless steel is preferred for environments where corrosion resistance is necessary.straight torsion spring

The design process of a straight torsion spring involves several key factors. Engineers must carefully consider parameters such as wire diameter, coil diameter, and total number of coils, as these elements influence the spring’s torque capacity and functional longevity. Moreover, computer-aided design (CAD) tools have become invaluable in this process, allowing for precise modeling and simulation of the spring’s behavior under various conditions.

Straight torsion springs find applications across a wide range of industries and devices. In automotive engineering, they are commonly used in mechanisms like hoods and trunk latches, where controlled torque is essential for secure closing. Similarly, they are an integral part of various household appliances, toys, and electronics, contributing to functionalities such as closure and release mechanisms.

Additionally, torsion springs can be employed in more specialized applications, such as in the aerospace industry for actuation systems, in medical devices for secure locking mechanisms, and in machinery where consistent force and stability are crucial. Their role in providing reliable and repeatable torque makes them a vital component in numerous designs.

In conclusion, straight torsion springs are fundamental mechanical elements that play a critical role in the functionality of many systems. Their unique characteristics and design versatility make them suitable for a wide array of applications. Understanding their principles of operation and design considerations is essential for engineers and designers aiming to harness their potential effectively in their respective fields. As industries continue to advance, the demand for innovative and reliable torsion spring solutions will likely grow, emphasizing the importance of ongoing research and development in this area.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025