- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Steel Wire Mesh Production Companies and Their Leading Solutions for Various Industries

The Essential Role of Steel Wire Mesh Manufacturers

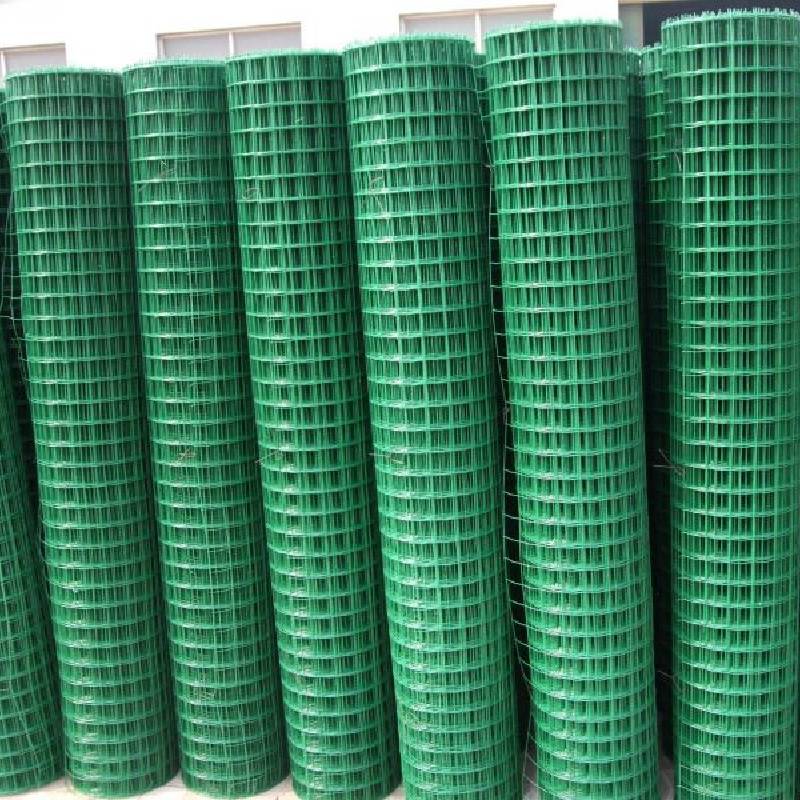

Steel wire mesh is a versatile and essential material widely used in various industries, including construction, agriculture, and industrial applications. As the demand for durable and reliable materials grows, steel wire mesh manufacturers play a crucial role in providing high-quality products that meet the diverse needs of their clients.

Understanding Steel Wire Mesh

Steel wire mesh consists of interwoven steel wires, creating a grid-like structure that is known for its strength and durability. This mesh can be produced in various configurations, including different wire gauges, mesh sizes, and coatings, making it adaptable for multiple applications. Common uses of steel wire mesh include reinforcing concrete, fencing for livestock, and even applications in the mining sector where stability and strength are paramount.

Importance of Steel Wire Mesh in Construction

In the construction industry, steel wire mesh is primarily utilized as a reinforcing element in concrete structures. It improves the tensile strength of concrete, preventing cracks and enhancing overall durability. Manufacturers typically produce two main types of wire mesh welded wire mesh and woven wire mesh. Welded wire mesh is made by welding intersecting wires at their junctions, forming a rigid structure. Woven wire mesh, on the other hand, is made by weaving the wires together, offering flexibility in applications where slight adjustments are needed.

As urbanization continues to rise around the globe, the demand for efficient and sustainable construction materials is on the rise

. Steel wire mesh manufacturers are continuously innovating to meet these demands by providing products that not only comply with strict safety standards but also contribute to the longevity of structures.Agricultural Applications

steel wire mesh manufacturers

Beyond construction, steel wire mesh is extensively used in agriculture. Farmers rely on it for fencing, protecting crops from pests and livestock. The mesh provides a robust barrier that can withstand weather conditions while ensuring that air and light reach the plants underneath. Additionally, in the aquaculture sector, steel wire mesh is used to create cages that enable efficient fish farming, ensuring the health and safety of aquatic life.

Industrial Uses

Steel wire mesh serves critical functions in various industrial applications as well. It is employed in filter systems, where its fine openings filter out materials while allowing fluids to pass through. Furthermore, manufacturers utilize steel wire mesh in conveyor belts, safety barriers, and shelving systems, showcasing its adaptability to different operational needs.

Innovation and Sustainability

As the market evolves, steel wire mesh manufacturers are embracing innovation and sustainability. Many companies are investing in research and development to produce mesh that is not only strong and resilient but also environmentally friendly. This includes using recycled materials in production processes and developing coatings that reduce environmental impact while providing corrosion resistance.

Moreover, manufacturers are increasingly focusing on automated production processes, which ensure higher precision and efficiency. This advancement not only reduces production costs but also minimizes waste, contributing further to sustainability efforts.

Conclusion

In conclusion, steel wire mesh manufacturers play a pivotal role in a multitude of industries, providing essential products that enhance safety, durability, and efficiency. Their commitment to innovation and sustainability ensures that they not only meet current demands but also anticipate future needs in an ever-changing market. As industries continue to evolve, the importance of quality steel wire mesh will undoubtedly remain a critical component in building a safer and more sustainable future.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025