- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Welded Wire Mesh Standards for Reinforcing Concrete Structures and Applications

Standard Welded Wire Mesh for Concrete Reinforcement

Concrete is one of the most widely used construction materials globally, renowned for its compressive strength and ability to withstand various environmental conditions. However, like any material, concrete has its limitations, particularly in terms of tensile strength. This is where welded wire mesh comes into play as a crucial component for reinforcing concrete structures, improving their durability and load-bearing capacity.

What is Welded Wire Mesh?

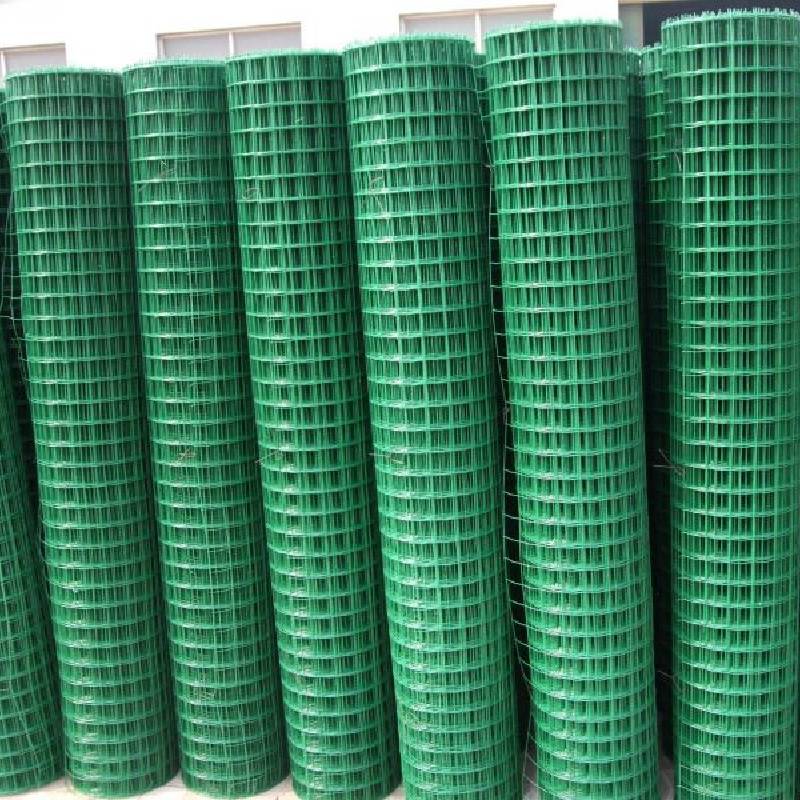

Welded wire mesh, also known as welded wire fabric (WWF), is an assembly of pre-welded steel wires that are arranged in a grid pattern. The wires are typically made of high-quality steel, which ensures both strength and durability. The welding process creates a strong bond between the wires at the intersections, resulting in a flexible and resilient mesh. Different sizes, shapes, and wire diameters are available to suit various structural needs and load requirements.

Importance of Reinforcement

Concrete, while excellent in compression, is weak in tension and can crack or fail under tensile stress. Reinforcement is essential to improve the tensile strength of concrete, allowing it to perform better under various load conditions, including bending and shear forces. By incorporating welded wire mesh into a concrete structure, builders can significantly enhance its structural integrity and longevity. The mesh provides uniform support and distributes loads evenly, reducing the likelihood of localized failures.

Typical Applications of Welded Wire Mesh

Welded wire mesh is commonly used in various construction applications, including

1. Slabs and Floors In concrete slabs, welded wire mesh helps resist cracking and enhances load distribution. It is used in residential, commercial, and industrial flooring systems.

2. Walls By reinforcing walls with welded wire mesh, builders can achieve improved structural performance and resistance to cracking, particularly in areas exposed to seismic activity.

standard welded wire mesh for concrete reinforcement

3. Paving Welded wire mesh is utilized in pavements and roadways to prevent cracking and to increase the lifespan of the surface.

4. Precast Concrete Products Many precast concrete components, such as panels, beams, and blocks, incorporate welded wire mesh to enhance their strength and durability.

5. Retaining Walls Reinforcing retaining walls with welded wire mesh helps them resist lateral earth pressures and increases their stability.

Standards and Specifications

When using welded wire mesh for concrete reinforcement, compliance with industry standards is vital. The American Society for Testing and Materials (ASTM) provides specifications for welded wire mesh, ensuring that it meets the required structural performance criteria. The most common standards include ASTM A185, which covers the general requirements for plain steel welded wire reinforcement, and ASTM A497, which pertains to deformed steel wire welded wire reinforcement.

These standards address various factors, such as wire diameter, mesh size, and the quality of welds. Using mesh that meets established standards is essential to ensure the safety and effectiveness of the reinforced concrete.

Installation Considerations

Proper installation of welded wire mesh is crucial for achieving its full benefits. It should be placed at the correct depth within the concrete pour to ensure adequate coverage and protect it from corrosion. Additionally, mesh should be adequately supported and positioned to avoid any movement during the concrete pour.

Conclusion

Standard welded wire mesh plays a vital role in reinforcing concrete structures, enhancing their strength, durability, and resistance to cracking. Its applications span across various construction projects, making it a versatile choice for builders and engineers. By adhering to established standards and ensuring proper installation, welded wire mesh contributes significantly to the longevity and safety of concrete constructions, making it an indispensable material in the field of construction and civil engineering. As the construction industry continues to evolve, the importance of quality reinforcement methods like welded wire mesh will remain pivotal in building resilient and sustainable structures.

share:

-

Understanding Wall Ties: Types and ImportanceNewsApr.28,2025

-

Top Products for Your Yard and Signage NeedsNewsApr.28,2025

-

The World of SpringsNewsApr.28,2025

-

Masonry Accessories: Essential for Building Strong FoundationsNewsApr.28,2025

-

Fencing Solutions for Every NeedNewsApr.28,2025

-

A Comprehensive Guide to Iron Wire for Your Construction NeedsNewsApr.28,2025

-

The Versatility of Wire Tension SpringsNewsApr.16,2025