- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Durable Stainless Steel Coil Springs for Various Industrial Applications and High Performance

The Versatility of Stainless Steel Coil Springs

Stainless steel coil springs are essential components widely used in various industries due to their durability and versatility. These springs are made from stainless steel, which offers superior resistance to corrosion, heat, and wear compared to other materials. This characteristic makes them ideal for applications in harsh environments where traditional materials might fail.

One of the primary advantages of stainless steel coil springs is their strength-to-weight ratio. They can handle significant loads while remaining relatively lightweight, making them perfect for use in automotive, aerospace, and industrial applications. For instance, in the automotive sector, these springs are commonly found in suspension systems where they help absorb shocks and maintain vehicle stability. In addition to improved performance, stainless steel coil springs contribute to the overall safety and comfort of the vehicle.

In the aerospace industry, the reliability of components is paramount. Stainless steel coil springs meet the rigorous performance requirements in this sector, ensuring that aircraft operate safely and efficiently. Their ability to function in extreme temperatures and resist fatigue over time makes them indispensable in various aerospace applications, from engine components to landing gear systems.

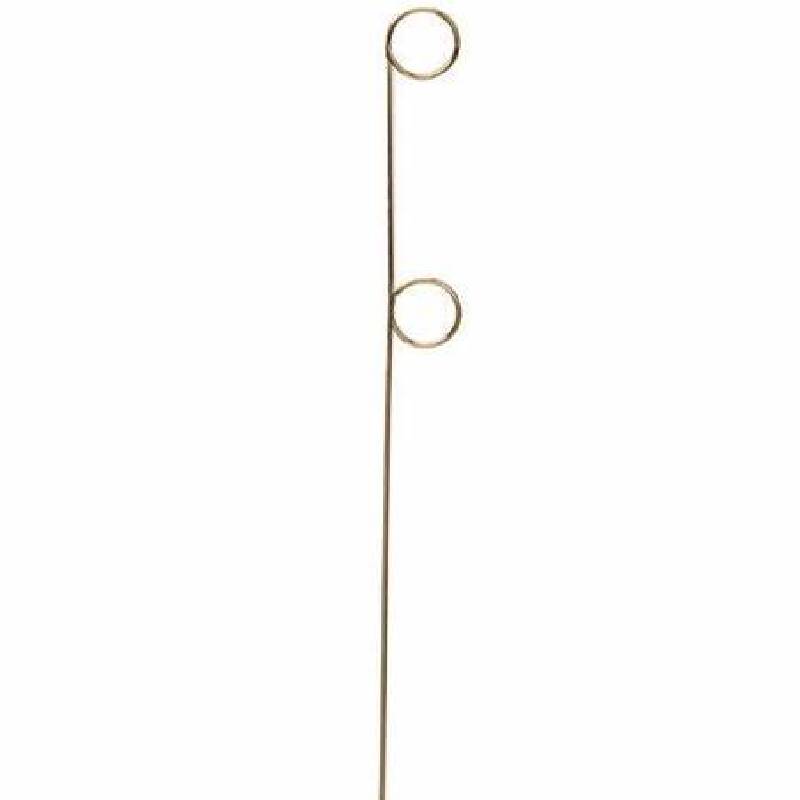

stainless steel coil springs

Another area where stainless steel coil springs shine is in medical equipment. These springs are often used in devices such as surgical instruments, hospital beds, and various diagnostic machines. The biocompatibility and easy sterilization properties of stainless steel ensure that these springs maintain high hygiene standards, which is crucial in medical settings.

Moreover, the manufacturing process of stainless steel coil springs allows for customization. Engineers can design springs in varying diameters, lengths, and coil designs to meet specific application requirements. This flexibility is particularly valuable in industries with unique and challenging demands.

Finally, stainless steel coil springs contribute to sustainability efforts. As they are recyclable, using these components can help reduce the environmental impact of production waste. Industries are increasingly recognizing the importance of sustainable practices, and opting for stainless steel components reflects a commitment to eco-friendly solutions.

In summary, stainless steel coil springs are integral to a wide array of applications across different sectors. Their strength, durability, resistance to corrosion, and ability to be tailored to specific needs make them an excellent choice for manufacturers and engineers. As technology continues to advance, the demand for high-performance materials like stainless steel coil springs will likely increase, further solidifying their role in modern engineering and design.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025