- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

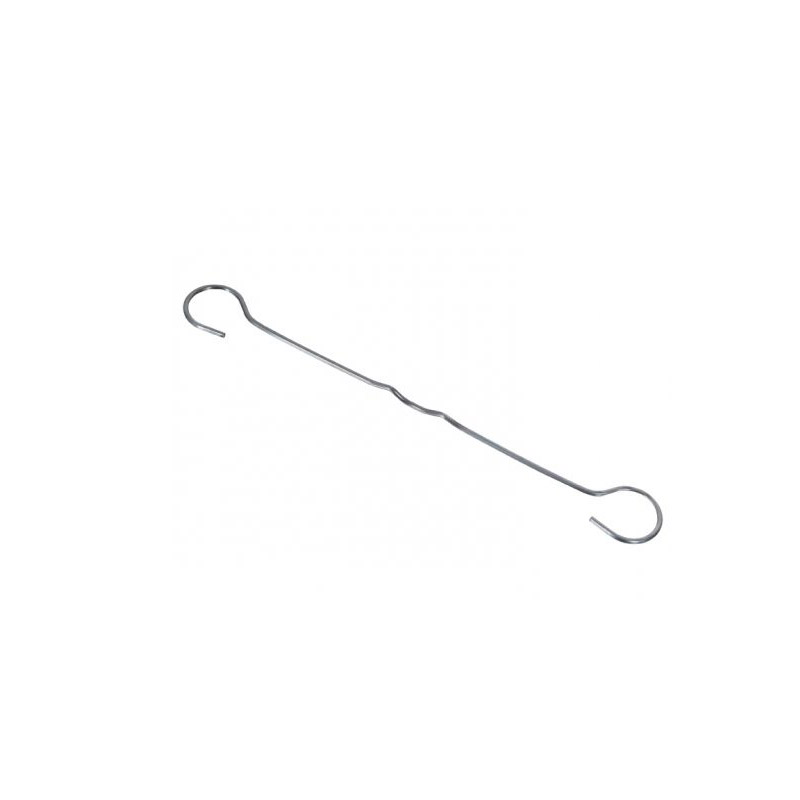

Stainless Steel Tension Spring - Durable & High-Quality Solutions

The Versatility of Stainless Steel Tension Springs

Stainless steel tension springs are key components in various industrial and commercial applications, offering a blend of durability, corrosion resistance, and reliable performance. These springs are designed to operate under tension, meaning they stretch when a load is applied, and return to their original shape when the load is removed. This unique ability makes them indispensable in numerous machinery and devices.

One of the primary benefits of using stainless steel for tension springs is its exceptional resistance to corrosion. Unlike traditional carbon steel, which can rust when exposed to moisture, stainless steel maintains its integrity even in harsh environments. This property makes stainless steel tension springs ideal for applications in the automotive, marine, and food processing industries, where exposure to water and chemicals can be a concern.

Moreover, stainless steel tension springs can operate effectively over a wide range of temperatures. They maintain their spring properties even in extreme heat or cold, making them suitable for use in climate-sensitive applications. This ability to perform reliably under various conditions adds to their versatility, allowing engineers to design systems with confidence.

stainless steel tension spring

Manufacturing tension springs from stainless steel also allows for precise control over spring characteristics. By adjusting the material grade, diameter, wire thickness, and coil design, manufacturers can tailor the spring to meet specific load requirements and performance criteria. This flexibility is crucial in industries such as aerospace and electronics, where precision engineering is paramount.

Additionally, the aesthetic appeal of stainless steel cannot be overlooked. Its sleek, shiny surface makes it suitable for applications where appearance matters, such as in consumer products and interior design elements. The combination of functionality and visual appeal ensures that stainless steel tension springs can meet both engineering and design requirements.

In conclusion, stainless steel tension springs are a vital component across various sectors due to their unique properties. Their corrosion resistance, temperature resilience, and customizable characteristics make them ideal for both industrial and commercial uses. As technology continues to advance, the demand for these reliable springs will likely increase, solidifying their place as an essential element in modern engineering and manufacturing. Whether in heavy machinery or delicate consumer electronics, stainless steel tension springs contribute significantly to the performance and longevity of a wide range of products.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025