- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

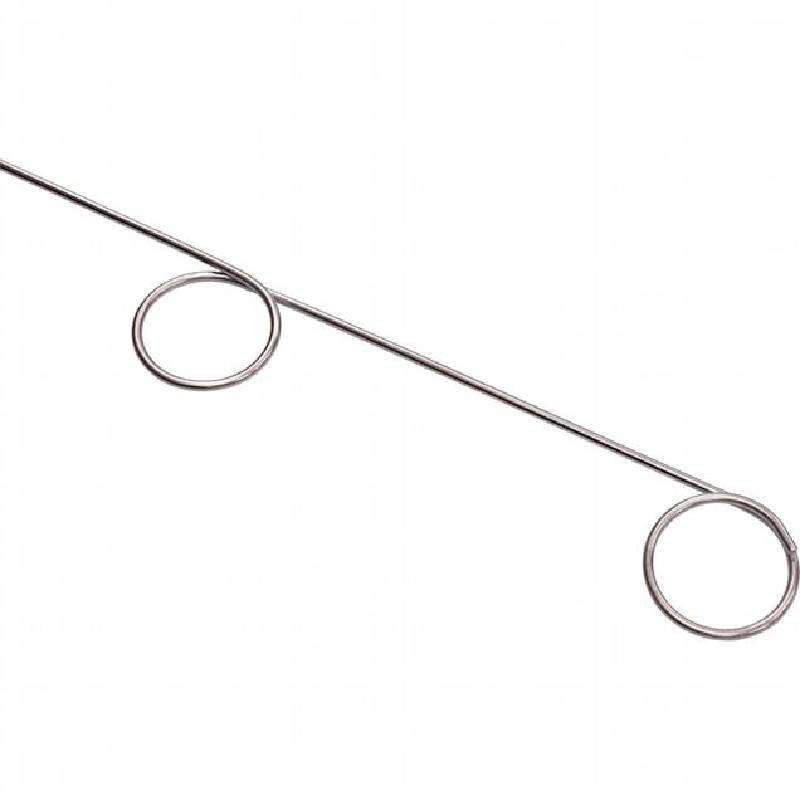

square wire springs

Understanding Square Wire Springs An Essential Component in Engineering

Square wire springs have become an increasingly popular choice in various engineering applications due to their unique properties and advantages over traditional round wire springs. These specialized springs are designed for specific applications where higher mechanical performance and stability are required. This article delves into the characteristics, manufacturing processes, and applications of square wire springs, highlighting their significance in modern engineering.

Characteristics of Square Wire Springs

One of the standout features of square wire springs is their geometric design, which offers improved surface contact compared to cylindrical counterparts. The square cross-section enables better load distribution, which can enhance the spring's resistance to deformation under stress. This design also reduces the potential for slippage, ensuring that the spring maintains its position and functionality even in demanding conditions.

Additionally, square wire springs exhibit excellent fatigue resistance, allowing them to endure repeated cycles of compression and extension without succumbing to wear and tear

. This resilience is particularly beneficial in industries where high durability and reliability are paramount, such as automotive, aerospace, and industrial machinery.Manufacturing Process

The manufacturing of square wire springs involves several stages, beginning with the production of square wire itself. This wire is typically made from high-carbon steel, stainless steel, or other alloys, depending on the desired properties of the final spring. The wire is produced through a drawing process that shapes it into a square cross-section while maintaining precise tolerances.

After the wire is formed, it undergoes heat treatment to improve its mechanical properties. This process involves heating the wire to high temperatures, followed by controlled cooling, which increases its strength and elasticity. Following heat treatment, the wire is cut to the required lengths and then coiled into the desired spring shape.

square wire springs

Finally, the springs are subjected to surface treatments, such as plating or coating, to enhance their resistance to corrosion and wear. Quality control checks are conducted at every stage of production to ensure that the springs meet industry standards and specifications.

Applications of Square Wire Springs

Square wire springs can be found in a myriad of applications across various industries. In the automotive sector, they are often used in suspension systems, where their robust design helps absorb shocks and vibrations, contributing to vehicle stability and comfort.

In the aerospace industry, square wire springs play a critical role in ensuring the reliability of safety mechanisms and equipment. Their high fatigue resistance is essential in applications where failure could have catastrophic consequences.

Moreover, these springs are also utilized in industrial machinery, consumer electronics, and household appliances. They can be designed to meet specific load and environmental conditions, making them a versatile choice for engineers aiming to optimize performance in a variety of systems.

Conclusion

Square wire springs represent a significant advancement in spring technology, offering unique advantages that cater to the demanding needs of various industries. Their superior load-bearing capabilities, enhanced fatigue resistance, and stable performance make them an indispensable component in modern engineering. As technology continues to evolve, the development and application of square wire springs will undoubtedly expand, further solidifying their role in enhancing the performance and reliability of mechanical systems.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025