- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

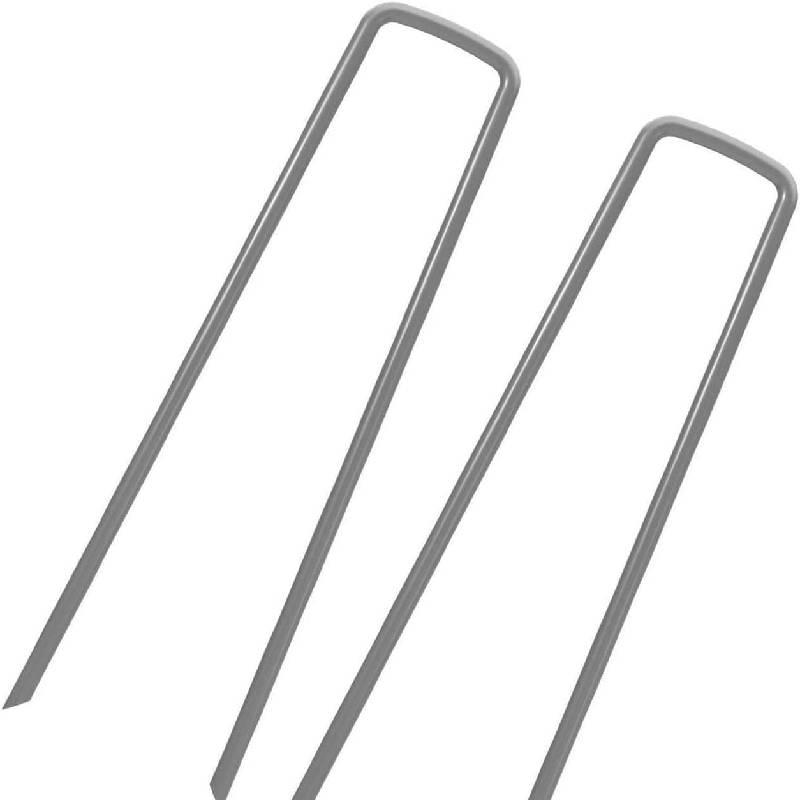

Optimizing Spring Wire Forming Techniques for Enhanced Performance and Precision

Understanding Spring Wire Forming A Comprehensive Overview

Spring wire forming is a specialized process used to create various types of springs and wire components that are essential in diverse industries, including automotive, aerospace, electronics, and consumer goods. The process involves the manipulation of wire materials into specific shapes under precise tension and dimensions. This article delves into the fundamentals of spring wire forming, the materials used, the techniques employed, applications, and its significance in modern engineering.

The Basics of Spring Wire Forming

At its core, spring wire forming is about taking high-quality wire and bending it into the desired configurations, typically using sophisticated machinery such as CNC (Computer Numerical Control) machines. The process can produce a wide range of spring types, including compression springs, extension springs, torsion springs, and wire forms. Each spring type has its distinct characteristics and applications based on how it stores and releases mechanical energy.

Materials Used in Spring Wire Forming

The selection of material for wire forming is crucial as it influences the spring's performance, durability, and flexibility. Common materials include - Music Wire Known for its high tensile strength, music wire is often used for small springs that require high fatigue resistance. - Stainless Steel This material offers excellent corrosion resistance, making it ideal for applications where springs are exposed to harsh environments. - Oil-Tempered Wire Often used in high-stress applications, oil-tempered wire is heat-treated to improve its strength and resilience. - Alloy Steel This material is used for heavy-duty springs that require high-performance characteristics and better fatigue life.

Techniques in Spring Wire Forming

The spring wire forming process can be executed through various techniques, namely 1. Coiling This is a primary method where wire is wound around a mandrel to create the coil shape. 2. Bending Used to create angular springs, bending alters the wire’s shape through precise angles and dimensions. 3. Torsion This involves twisting the wire to create torsional forces typically used in torsion springs. 4. Cutting and Shaping After the initial forming, the spring may require cutting to specific lengths or additional shaping to meet design specifications.

Computerization has significantly enhanced these techniques, with CNC machines allowing for high precision in dimensions, repeatability, and quicker production runs.

spring wire forming

Applications of Spring Wire Forming

Springs play a pivotal role in numerous applications. In the automotive industry, springs are used in suspension systems, brakes, and various mechanisms. In electronics, tiny springs are often utilized in switches and connectors. Moreover, in consumer products, whether it's a ballpoint pen or a mattress, springs significantly contribute to function and comfort.

Additionally, industries such as aerospace demand highly specialized springs that must endure extreme conditions, making the quality of spring wire forming critical in ensuring reliability and safety.

The Importance of Quality Control

Given the critical functions springs serve, quality control in spring wire forming cannot be overstated. Manufacturers often employ stringent testing protocols including tensile tests, fatigue testing, and dimensional checks to ensure that the springs meet design specifications and perform reliably under pressure.

Furthermore, innovative techniques such as automated inspection and the use of advanced materials continue to enhance quality assurance in spring wire manufacturing.

Conclusion

Spring wire forming is an intricate yet essential manufacturing process that combines artistry and engineering. As industries evolve and seek higher performance standards, the demand for advanced spring designs and materials will undoubtedly grow. Understanding the nuances of spring wire forming is crucial for engineers and manufacturers aiming to produce reliable, high-quality spring components that are foundational to countless applications. In a world driven by innovation and efficiency, the role of spring wire forming will remain significant, shaping the future of technology and design across various industries.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025