- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

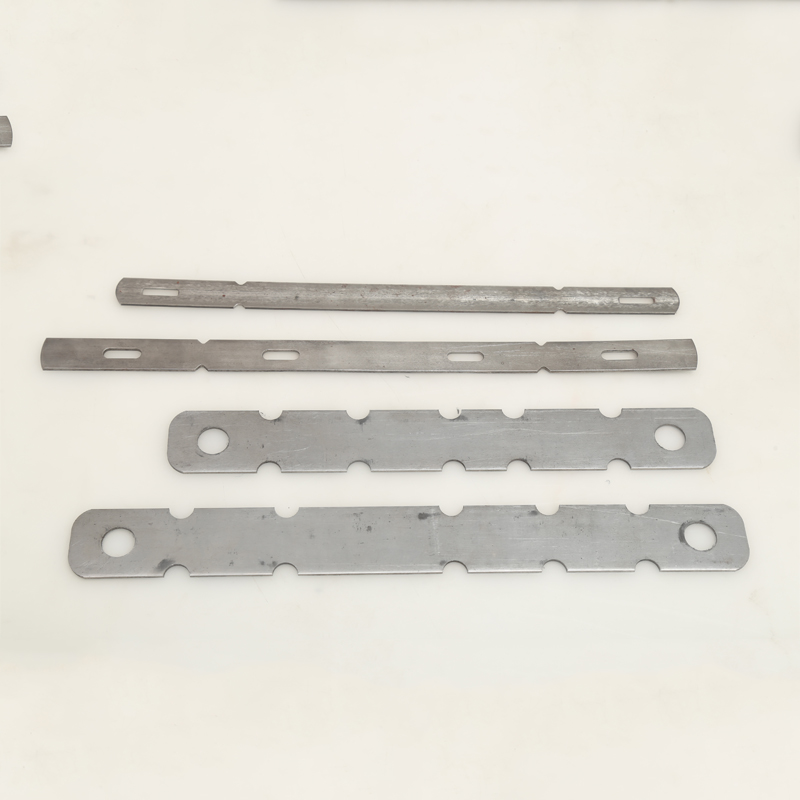

spring steel coil

Understanding Spring Steel Coil Properties, Applications, and Benefits

Spring steel coil is a specially engineered steel that is designed to resist deformation and return to its original shape when subjected to heavy loads. This unique property makes it an essential material in various applications, especially where elasticity and strength are crucial. Typically, high carbon steel is used to create spring steel, which exhibits excellent hardness, durability, and fatigue resistance. In this article, we will delve into the properties, applications, and benefits of spring steel coils.

Properties of Spring Steel Coil

1. High Carbon Content Spring steels have a high percentage of carbon, usually ranging from 0.5% to 1.0%. This increase in carbon content enhances their hardness and tensile strength, making them ideal for dynamic and static applications.

2. Elasticity One of the most notable features of spring steel coil is its ability to return to its original shape after deformation. This property is measured by the modulus of elasticity, with spring steel showing superior performance compared to other types of steel.

3. Fatigue Resistance Spring steel is designed to withstand cyclic loading, meaning it can endure repetitive stresses without succumbing to fatigue. This makes it particularly suited for applications where components are continually flexed or compressed.

4. Temperability Spring steel coils can be heat-treated to achieve desired mechanical properties. This tempering process refines the internal structure of the steel, allowing manufacturers to tailor the strength and flexibility of the final product according to specific requirements.

5. Versatility Available in various grades and thicknesses, spring steel coils can be manufactured to meet specific dimensional and performance specifications. This versatility makes it suitable for a wide range of applications across different industries.

Applications of Spring Steel Coil

The unique properties of spring steel coils lend themselves to a myriad of applications, including but not limited to

1. Automotive Industry Spring steel is heavily utilized in the automotive sector for manufacturing suspension springs, clutch springs, and other components that must endure variable loads and stresses.

2. Industrial Machinery Many industrial machines rely on springs and tensioning mechanisms to operate efficiently. Spring steel coils are commonly used in the production of machinery components such as conveyor systems, levers, and other applications that require significant flexibility and strength.

spring steel coil

4. Construction The construction industry utilizes spring steel for reinforcement and support structures, thanks to its ability to withstand dynamic loads and pressures.

5. Spring Manufacturers As the name suggests, sprig steel is the primary material for manufacturing various types of springs, including coil springs, leaf springs, and compression springs.

Benefits of Spring Steel Coil

Investing in spring steel coils offers numerous advantages, making it a preferred choice for manufacturers and engineers

1. Durability The high strength of spring steel mitigates wear and tear, ensuring components have a longer service life compared to those made from softer materials.

2. Improved Performance Due to its exceptional elasticity and fatigue resistance, equipment and devices made from spring steel can operate more efficiently and effectively, leading to higher productivity.

3. Cost-Effectiveness Although spring steel may have a higher initial cost than other materials, its longevity and performance lead to lower maintenance costs and reduced replacement needs, offering long-term savings.

4. Customizability With the ability to tailor properties via heat treatment and variations in manufacturing processes, spring steel coils can be customized to fit unique applications, enhancing their value in specific projects.

5. Environmental Resistance Many spring steel coils are treated to resist corrosion, ensuring that they maintain their integrity and performance even in challenging environments.

In conclusion, spring steel coils are an essential material in numerous industries due to their unique properties, applications, and inherent benefits. By providing a combination of strength, elasticity, and durability, they play a critical role in the performance and efficiency of a wide range of products and components. Choosing spring steel coils can lead to better manufacturing outcomes, increased product lifespan, and overall improvements in operational efficiency.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025