- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

High-Quality Spring Steel Coils for Durable Applications

Understanding Spring Steel Coils Properties and Applications

Spring steel coils are essential materials used across various industries, particularly in the manufacturing of springs, automotive components, and machinery. Characterized by their unique physical properties, these coils are designed to provide significant strength and elasticity, making them ideal for applications that require high resilience and durability.

Spring steel is typically produced from high-carbon steel, offering impressive tensile strength, wear resistance, and the ability to maintain shape after deformation. The most common grades utilized for spring steel coils include ASTM A228, A313, and A421, each having distinct qualities suited for specific applications. For instance, ASTM A228 is often used for music wire due to its excellent strength and surface finish, while A313 is preferred for general-purpose springs.

One of the key attributes of spring steel coils is their superior elasticity. This property enables the materials to endure repeated stress and fatigue without permanent deformation. This resilience is crucial in applications where springs undergo continuous cycling, such as in automotive suspensions, mechanical assemblies, and heavy machinery.

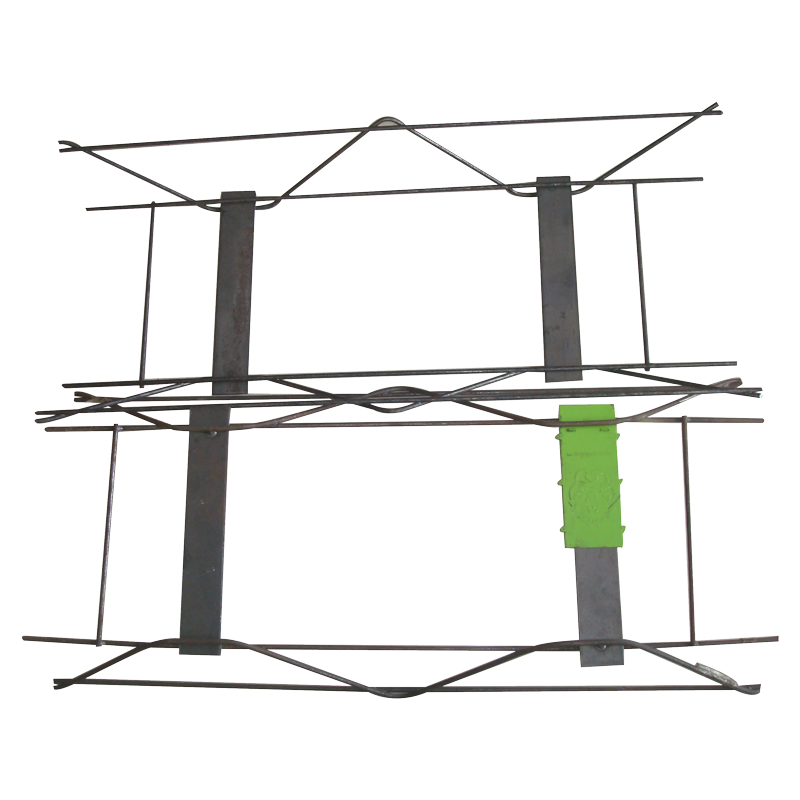

spring steel coil

The manufacturing process of spring steel coils involves careful control of chemical composition and heat treatment. Heat treatment processes such as hardening and tempering enhance their mechanical properties, allowing manufacturers to tailor the coils' characteristics to meet specific performance requirements. These processes not only improve the strength-to-weight ratio but also increase the operational lifespan of the springs made from these coils.

In addition to their mechanical properties, spring steel coils also offer excellent corrosion resistance when treated with appropriate coatings or finishes. This aspect is crucial for applications exposed to harsh environmental conditions, ensuring reliability and longevity in service.

Spring steel coils are utilized in a myriad of applications, ranging from automotive industries—where they are used in leaf springs and suspension systems—to electronics, where they serve in relays and switches. The versatility of spring steel makes it an invaluable component in modern engineering and manufacturing sectors.

In conclusion, spring steel coils play a vital role in numerous applications due to their remarkable combination of strength, elasticity, and durability. Understanding their properties and the processes behind their production allows industries to leverage these materials effectively, leading to innovative designs and efficient solutions in various engineering challenges. As technology advances, the demand for high-performance materials like spring steel coils will only continue to grow, driving further research and development in this field.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025