- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Mar . 05, 2025 05:21

Back to list

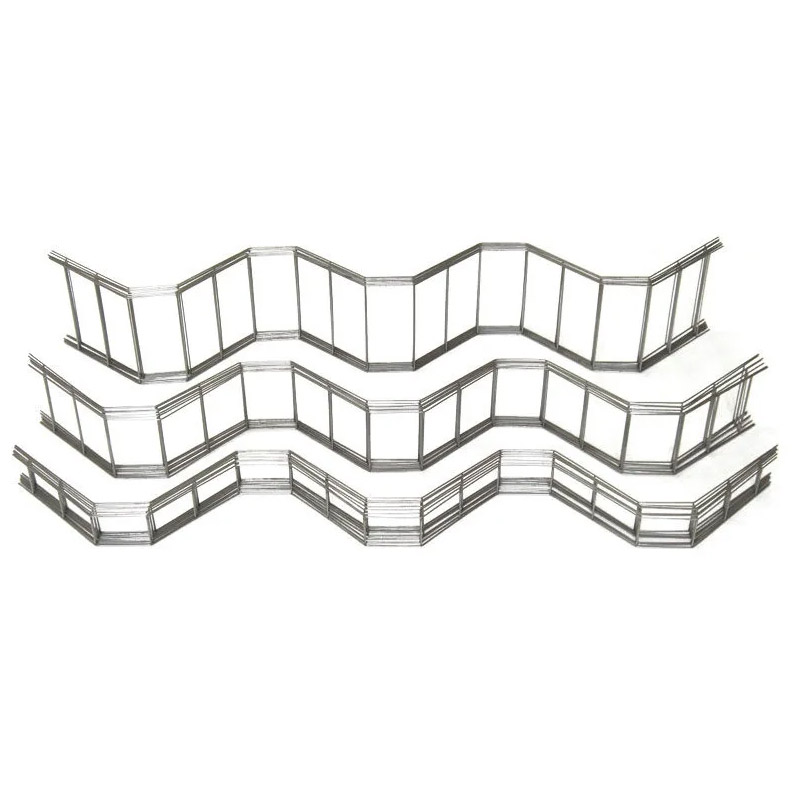

Compression Springs

In the world of modern engineering and manufacturing, the need for high-quality small compression springs is ever-present. These indispensable components play a critical role in a myriad of applications, from automotive systems to electronic devices. When searching for small compression springs for sale, one must consider several factors that ensure both product quality and optimal performance.

Trustworthiness, a key factor in any transaction, is built through consistent delivery of quality products and superior customer service. A trusted vendor will guide clients through the selection process, offering detailed consultation services to help assess the best options based on the intended use case. They should provide comprehensive product information and specifications readily available, both online and through direct inquiry, ensuring that potential buyers make informed, confident decisions. Another crucial consideration is the buying process itself. An efficient online or direct purchase system, complete with easy-to-use tools for product selection, can significantly enhance the buyer’s experience. From user-friendly interfaces to knowledgeable customer service representatives, every aspect of the transaction should streamline the procurement process, reducing lead times and eliminating frustration. Furthermore, exploring customer testimonials and reviews can provide invaluable insights into the supplier’s reputation in the market. Positive feedback from previous clients about the durability, reliability, and performance of the springs helps solidify a brand’s credibility. Independent reviews often highlight elements that might not be immediately apparent, assisting prospective buyers in making more informed decisions. In conclusion, acquiring small compression springs demands careful consideration of several analytical and experiential factors. Emphasizing quality, expert guidance, and supplier reliability ensures that these vital components will perform flawlessly in their designated roles. By partnering with reputable suppliers who offer bespoke solutions and robust quality assurance processes, buyers can rest assured that their systems are supported by the finest springs available. This thoughtful approach not only maximizes efficiency and safety but also fortifies the trust and authority of a business in a highly competitive environment.

Trustworthiness, a key factor in any transaction, is built through consistent delivery of quality products and superior customer service. A trusted vendor will guide clients through the selection process, offering detailed consultation services to help assess the best options based on the intended use case. They should provide comprehensive product information and specifications readily available, both online and through direct inquiry, ensuring that potential buyers make informed, confident decisions. Another crucial consideration is the buying process itself. An efficient online or direct purchase system, complete with easy-to-use tools for product selection, can significantly enhance the buyer’s experience. From user-friendly interfaces to knowledgeable customer service representatives, every aspect of the transaction should streamline the procurement process, reducing lead times and eliminating frustration. Furthermore, exploring customer testimonials and reviews can provide invaluable insights into the supplier’s reputation in the market. Positive feedback from previous clients about the durability, reliability, and performance of the springs helps solidify a brand’s credibility. Independent reviews often highlight elements that might not be immediately apparent, assisting prospective buyers in making more informed decisions. In conclusion, acquiring small compression springs demands careful consideration of several analytical and experiential factors. Emphasizing quality, expert guidance, and supplier reliability ensures that these vital components will perform flawlessly in their designated roles. By partnering with reputable suppliers who offer bespoke solutions and robust quality assurance processes, buyers can rest assured that their systems are supported by the finest springs available. This thoughtful approach not only maximizes efficiency and safety but also fortifies the trust and authority of a business in a highly competitive environment.

share:

Next:

Latest news

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025