- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Small Coil Springs for Various Applications and Custom Solutions in Engineering Design

Understanding Small Coil Springs Applications and Benefits

Small coil springs are an essential component in various mechanical systems, providing a reliable and efficient solution for a multitude of applications. These springs are characterized by their helical shape, which allows them to store and release energy when compressed or extended. Made from high-quality materials, small coil springs are designed to withstand significant stress and strain while maintaining their shape and functionality.

One of the primary advantages of small coil springs is their versatility. They can be found in a wide array of devices, ranging from household appliances to automotive components. In the automotive industry, for instance, small coil springs are crucial in the suspension system, providing support for the vehicle’s weight and ensuring a smooth ride by absorbing shocks from the road. Similarly, they are employed in door locks, pen mechanisms, and various consumer electronics, making them indispensable in everyday life.

Moreover, small coil springs come in different sizes, materials, and configurations to meet specific requirements. Common materials used in the production of coil springs include stainless steel, music wire, and alloy steel. The choice of material not only affects the spring's durability and performance but also influences its cost and suitability for particular environments. For instance, stainless steel springs are highly resistant to corrosion, making them ideal for applications in harsh conditions, such as marine environments.

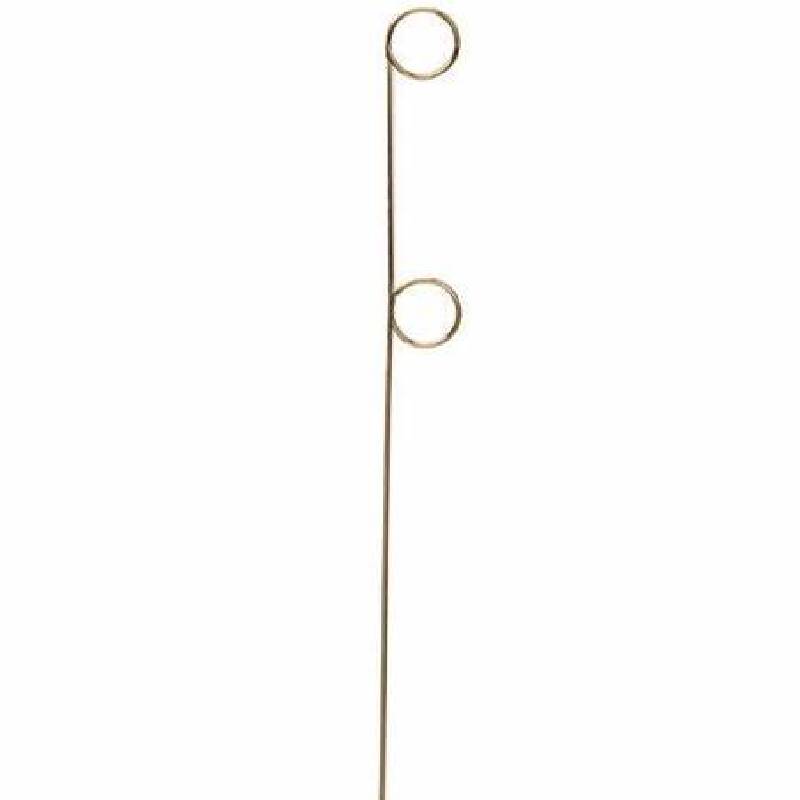

small coil springs

In addition to their physical properties, small coil springs offer significant design flexibility. Engineers can customize these springs in terms of wire diameter, number of coils, and overall dimensions based on the specific needs of a project. This ability to tailor spring characteristics allows for the optimization of performance and functionality, ensuring that the spring effectively meets the demands of its application.

It's also important to note that the manufacturing process of small coil springs has evolved significantly over the years. Advances in technology have facilitated the production of high-precision springs that adhere to strict quality control standards. Computer-aided design (CAD) and computer numerical control (CNC) machining have made it possible to produce springs with exact specifications, resulting in enhanced performance and reliability.

In terms of maintenance, small coil springs require minimal care when properly designed and installed. However, it is essential to conduct regular inspections to ensure they are not subjected to extreme loads or fatigue, which could lead to failure. Addressing these issues early on can extend the life of the spring and enhance the overall performance of the system in which it operates.

In conclusion, small coil springs are vital components that play a crucial role in many applications across diverse industries. Their ability to store and release energy efficiently, combined with their design flexibility and durability, makes them a preferred choice for engineers and manufacturers alike. As technology continues to advance, we can expect further improvements in the design and manufacturing of small coil springs, ensuring their place in the future of mechanical systems. Whether in a simple pen or a complex automotive suspension, small coil springs are fundamental to the function and efficiency of countless devices we rely on daily.

share:

-

Understanding Wall Ties: Types and ImportanceNewsApr.28,2025

-

Top Products for Your Yard and Signage NeedsNewsApr.28,2025

-

The World of SpringsNewsApr.28,2025

-

Masonry Accessories: Essential for Building Strong FoundationsNewsApr.28,2025

-

Fencing Solutions for Every NeedNewsApr.28,2025

-

A Comprehensive Guide to Iron Wire for Your Construction NeedsNewsApr.28,2025

-

The Versatility of Wire Tension SpringsNewsApr.16,2025