- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

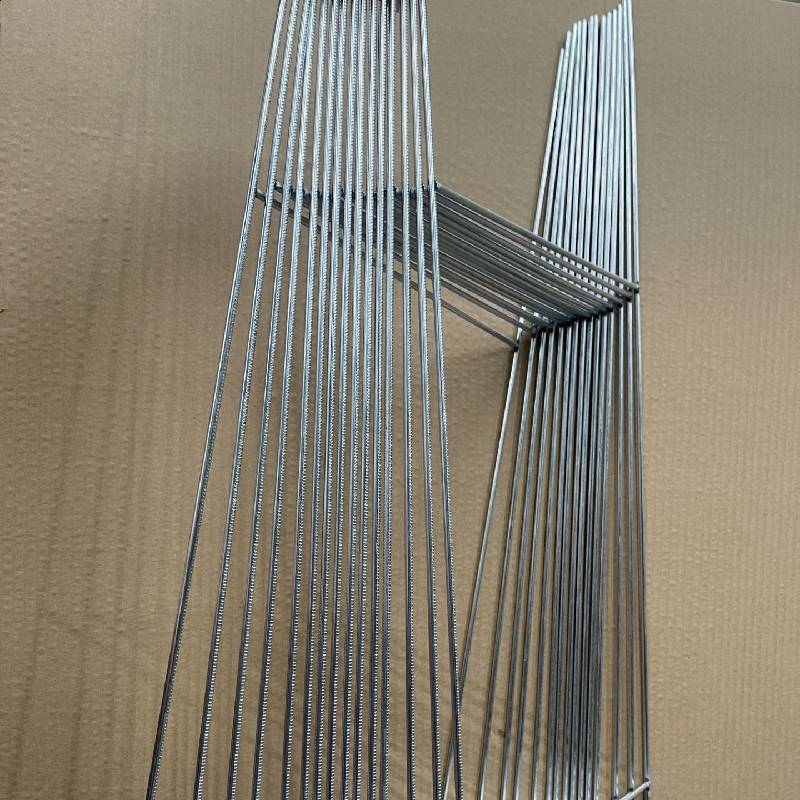

rolled steel bar

Understanding Rolled Steel Bars Applications, Types, and Benefits

Rolled steel bars, a fundamental product in the steel industry, play a crucial role in various engineering and construction applications. These bars, produced through the processes of hot or cold rolling, serve as essential materials in a myriad of sectors, including construction, automotive, and manufacturing. This article will explore the characteristics, types, applications, and advantages of rolled steel bars.

What Are Rolled Steel Bars?

Rolled steel bars are long, rectangular steel products that are processed through rolling mills, where steel is heated and transformed into a desired shape by passing it through rollers. The process can be classified into two major types hot rolling and cold rolling. Hot rolling involves heating steel above its recrystallization temperature and then shaping it, leading to improved workability and reduced risk of cracking. Conversely, cold rolling occurs at or near room temperature, which enhances the strength and finish of the steel, making it more suitable for precision applications.

Types of Rolled Steel Bars

There are several types of rolled steel bars, categorized based on their shape, composition, and processing methods. The most common shapes include

1. Round Bars These are circular cross-section bars and are widely used in construction and manufacturing for various applications, such as shafts, pins, and fasteners.

2. Square Bars Characterized by their square cross-section, square bars are often used in fabrication and construction, particularly for structural supports and frames.

3. Flat Bars These bars, having a rectangular cross-section, are versatile and used in different applications, including brackets, frames, and as base plates.

4. Hexagonal Bars These are used in applications requiring specific geometric shapes, often in the manufacturing of specialized components.

5. Reinforcing Bars (Rebars) Typically used in concrete reinforcement, rebars are manufactured with ridges to improve bonding with concrete, crucial for enhancing structural strength.

Applications of Rolled Steel Bars

Rolled steel bars are integral to various industries due to their strength, versatility, and cost-effectiveness. Key applications include

rolled steel bar

- Construction Rolled steel bars are extensively used in the construction industry for structural framing, supports, reinforcement, and in the manufacturing of various construction materials. Their strength and durability make them ideal for high-load-bearing applications.

- Manufacturing and Fabrication These bars serve as raw materials in manufacturing processes for machinery, tools, and other engineered components, providing the necessary strength and flexibility.

- Automotive Industry In the automotive sector, rolled steel bars are utilized for chassis, suspension parts, and other components that require high strength and resilience to stress

.- Shipbuilding and Offshore Industries Rolled steel bars are used in ship components and offshore structures due to their resistance to corrosion and ability to withstand harsh environmental conditions.

Benefits of Using Rolled Steel Bars

The advantages of rolled steel bars make them an indispensable material in modern industry. These benefits include

1. Strength and Durability Rolled steel bars offer excellent tensile strength and impact resistance, making them suitable for demanding applications.

2. Versatility Available in different shapes and sizes, they can be tailored to suit various industrial needs, promoting efficiency in design and production.

3. Cost-Effectiveness Compared to other materials, rolled steel bars provide a competitive cost-to-performance ratio, often making them the preferred choice for both manufacturers and builders.

4. Recyclability Steel is one of the most recycled materials globally. The use of rolled steel bars contributes to sustainability, as they can be recycled multiple times without losing quality.

5. Consistency and Reliability The rolling process ensures uniform properties in rolled steel bars, which is crucial in applications where precision and reliability are paramount.

Conclusion

Rolled steel bars are the backbone of numerous industries, combining strength, versatility, and cost-effectiveness. Their various forms and applications underscore their importance in modern engineering and construction. As industries continue to evolve, the demand for high-quality rolled steel bars will remain strong, contributing to advancements in technology and infrastructure development worldwide. Whether in skyscrapers, vehicles, or machinery, the impact of rolled steel bars is undeniable and will continue to shape the future.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025