- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

reinforcing bar positioners

Understanding Reinforcing Bar Positioners Importance, Types, and Applications

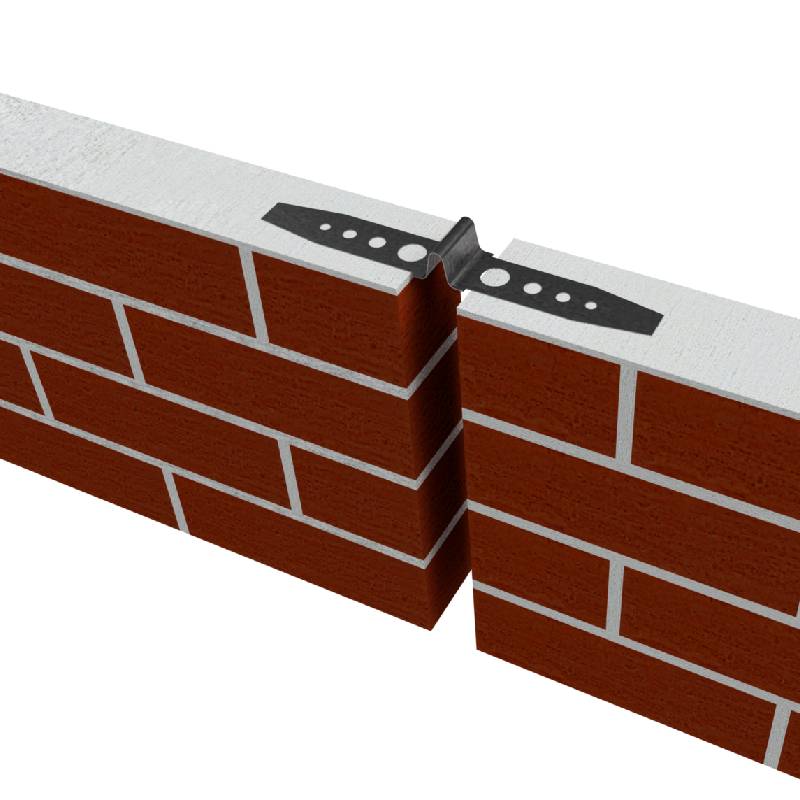

Reinforcing bar positioners, commonly known as rebar positioners, play a crucial role in the construction industry, particularly in the reinforcement of concrete structures. These specialized tools are designed to ensure that rebar is correctly positioned within a concrete formwork, helping to improve structural integrity and overall safety.

Concrete is a material that is strong in compression but weak in tension. This is where rebar, typically made from steel, comes into play. By embedding reinforcing bars within the concrete, engineers can significantly enhance tensile strength, allowing structures to withstand various loads and stresses. However, the effectiveness of rebar greatly depends on its placement during the construction process, making the use of positioners indispensable.

Types of Reinforcing Bar Positioners

Reinforcing bar positioners come in various designs, each aimed at addressing specific requirements in construction. They can be classified into several categories based on their functionality

1. Spacers These are commonly used to maintain the correct distance between the rebar and the formwork. Spacers are essential for ensuring that the rebar is adequately covered by concrete, thereby preventing corrosion and other durability issues. They can be made from different materials such as plastic, steel, or concrete.

2. Supports Support positioners hold the rebar in place, preventing it from shifting during the placement of concrete. This is particularly crucial in larger scale projects where the sheer weight of the rebar may cause accidental movement. Various support designs are available, including wire supports and chair supports.

3. Docking Systems Advanced rebar positioners utilize docking systems that allow for easy alignment and adjustment of multiple rebar grids. These systems enhance efficiency, especially in complex structures requiring precise arrangements of rebar.

4. Custom Positioners For specific construction needs, custom positioners can be designed to accommodate unique shapes or sizes of rebar. These are often tailored for unique architectural features or engineering requirements.

Importance of Using Rebar Positioners

The use of rebar positioners in concrete construction is vital for several reasons

reinforcing bar positioners

- Structural Integrity Proper positioning of rebar ensures that it is optimally located to bear the tensile loads. This enhances the overall stability and lifespan of the structure.

- Quality Control Positioners help maintain consistency in rebar placement, reducing the risk of human error. This consistency is critical for meeting engineering specifications and ensuring the quality of the finished concrete.

- Safety Misplaced rebar can lead to structural failures, posing safety risks

. Proper use of positioners minimizes these risks, protecting construction workers and future occupants alike.- Efficiency By speeding up the process of setting up rebar, positioners contribute to overall project efficiency. Reduced labor time and lowered material waste are direct benefits.

Applications in Different Industries

Rebar positioners are utilized across various construction sectors, including

- Residential Buildings Ensuring that foundational elements can support structural loads safely. - Commercial Construction In the construction of high-rise buildings, positioners help maintain the integrity of complex frameworks. - Infrastructure Projects Bridges, tunnels, and roadways require meticulous rebar positioning to endure heavy traffic loads and environmental stresses.

- Precast Concrete In precast facilities, positioners aid in producing high-quality elements efficiently, ensuring consistent outcomes.

Conclusion

In summary, reinforcing bar positioners are vital tools in modern construction. By ensuring the correct placement of rebar, they enhance the strength and durability of concrete structures while promoting safety and efficiency in the construction process. As the industry continues to evolve, the development of innovative rebar positioners will remain essential, ensuring that we meet the growing demands of infrastructure and building design. Understanding these tools not only helps construction professionals improve their work but also equips them with the necessary knowledge to advocate for best practices in structural engineering.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025