- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

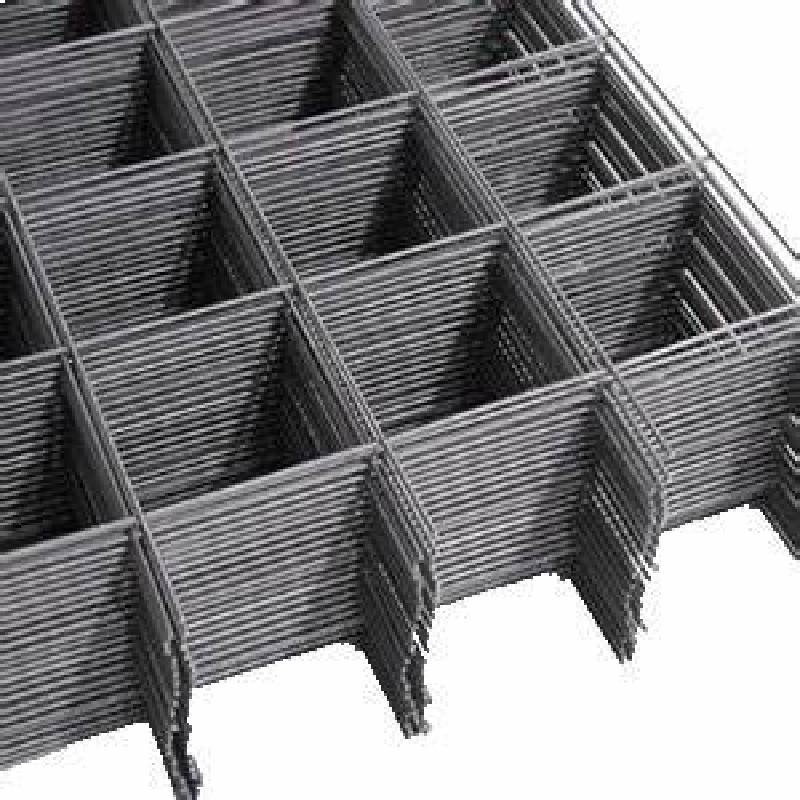

High-Quality Wire Mesh for Durable and Reliable Applications in Various Industries

Understanding Quality Wire Mesh A Comprehensive Overview

Wire mesh, also known as wire cloth or wire screen, is an essential material found across various industries, from construction and agriculture to manufacturing and filtration. The quality of wire mesh is crucial as it directly affects the performance and longevity of the products it is used in. In this article, we will explore the key factors that define quality wire mesh and its applications, emphasizing why choosing high-quality wire mesh is vital for your projects.

What is Wire Mesh?

Wire mesh is made from a network of wires that are woven, welded, or knitted together to form a grid pattern. The material can vary, with options including stainless steel, galvanized steel, aluminum, and more. Each of these materials offers different attributes suited for specific applications. For example, stainless steel wire mesh is known for its durability and resistance to corrosion, making it an ideal choice for outdoor and harsh environment uses.

Factors Defining Quality Wire Mesh

1. Material Composition The type of metal used in manufacturing wire mesh is paramount. High-quality wire mesh typically uses alloys or materials that resist rust, wear, and corrosion. For instance, stainless steel is revered for its strength and resistance to oxidation, while PVC-coated wire mesh is often utilized in applications requiring additional protection from harsh chemical environments.

2. Wire Diameter The diameter of the wires in the mesh significantly influences its strength and applicability. Thicker wires usually provide better tensile strength and resistance to deformation under stress, while finer meshes can filter smaller particles. The appropriate wire diameter is determined based on the intended use of the mesh.

3. Mesh Size and Opening The size of the openings in the mesh determines what can pass through and is critical in filtration applications. Quality wire mesh is manufactured to precise specifications, ensuring consistent opening sizes that meet industrial standards. Fine mesh is used for filtration and separation, while larger openings are suitable for applications like fencing and construction.

4. Welding Technique For welded wire mesh, the quality of welding is crucial. High-quality wire meshes are typically created using strong, uniform welding techniques ensuring firm connections that can withstand various stresses and strains without breaking apart.

quality wire mesh

5. Coating and Finishing Many wire meshes undergo treatments such as galvanization or plastic coating to enhance durability. A quality finish protects the wire from rust and corrosion and can also provide aesthetically pleasing options for architectural applications.

Applications of Quality Wire Mesh

1. Construction In the construction industry, wire mesh is used in concrete reinforcement, fencing, and various architectural elements. High-quality wire mesh ensures structural integrity and safety in buildings and constructions.

2. Agriculture Quality wire mesh is utilized in agriculture for fencing livestock, creating hatcheries, and protecting crops. The durability of the mesh ensures that it withstands the outdoor elements and provides safe enclosures.

3. Filtration In various industries, including food processing and pharmaceuticals, wire mesh is essential for filtering liquids and solids. High-quality mesh guarantees that filtration meets safety standards while providing longevity and efficacy.

4. Manufacturing Manufacturers rely on wire mesh for sorting, sieving, and securing products. Quality mesh increases productivity by minimizing downtime due to maintenance or replacement of inferior products.

Conclusion

In conclusion, the quality of wire mesh plays an indispensable role in its performance and effectiveness across various applications. When selecting wire mesh, it is vital to consider factors such as material composition, wire diameter, mesh size, welding techniques, and protective coatings. Investing in high-quality wire mesh not only enhances the durability of your projects but also ensures safety and efficiency in their intended applications. Whether you’re in construction, agriculture, manufacturing, or any other industry that requires wire mesh, making informed choices will lead to superior outcomes and long-term satisfaction.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025