- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

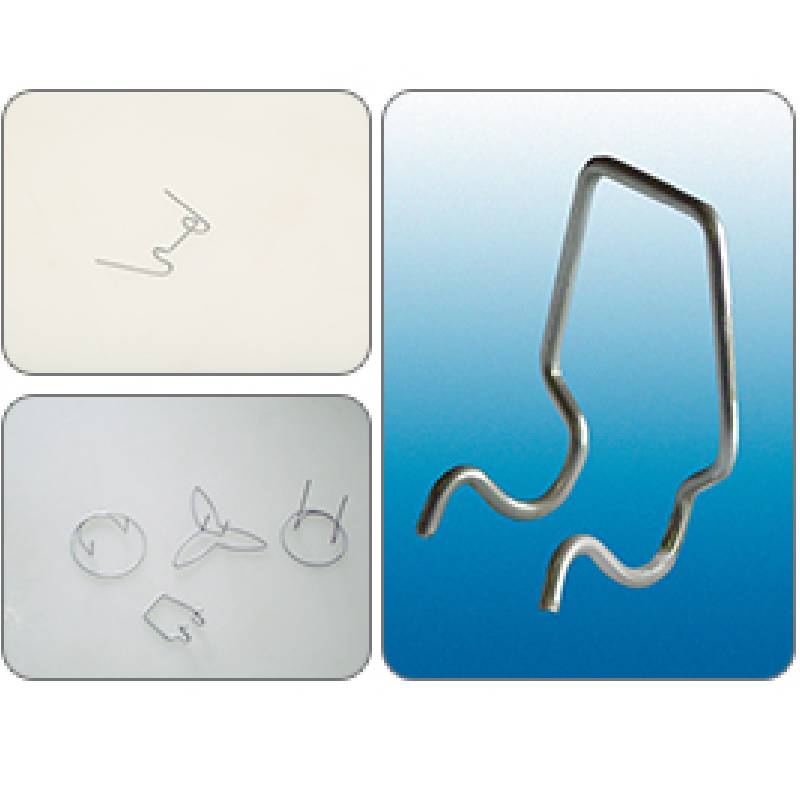

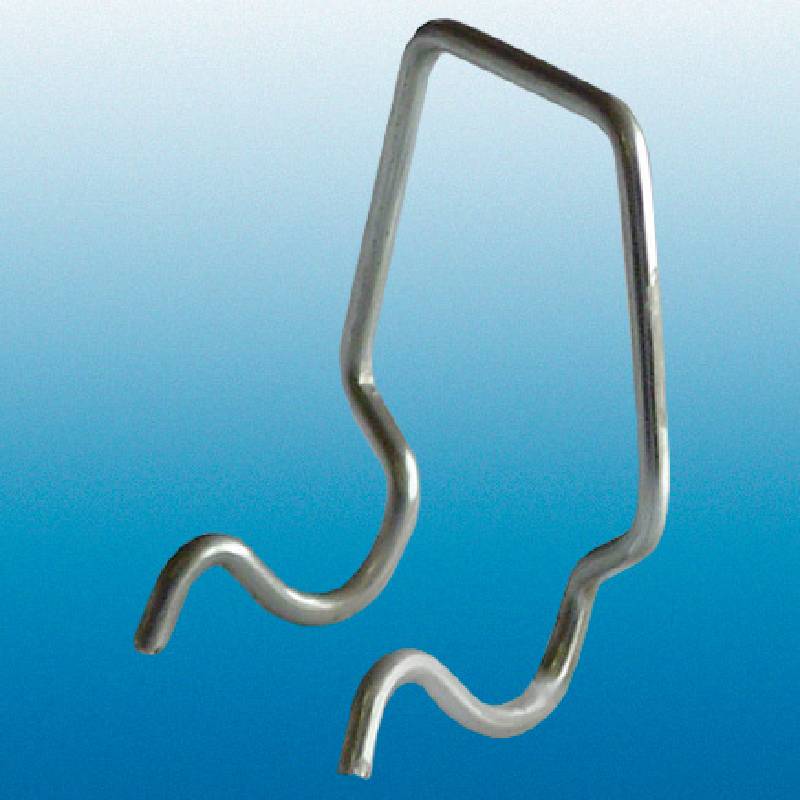

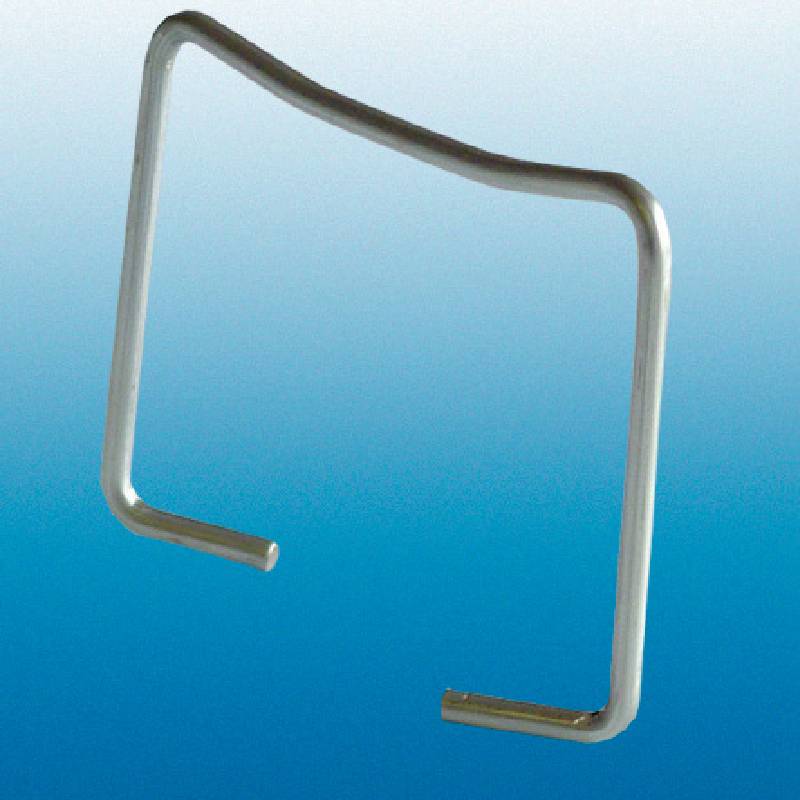

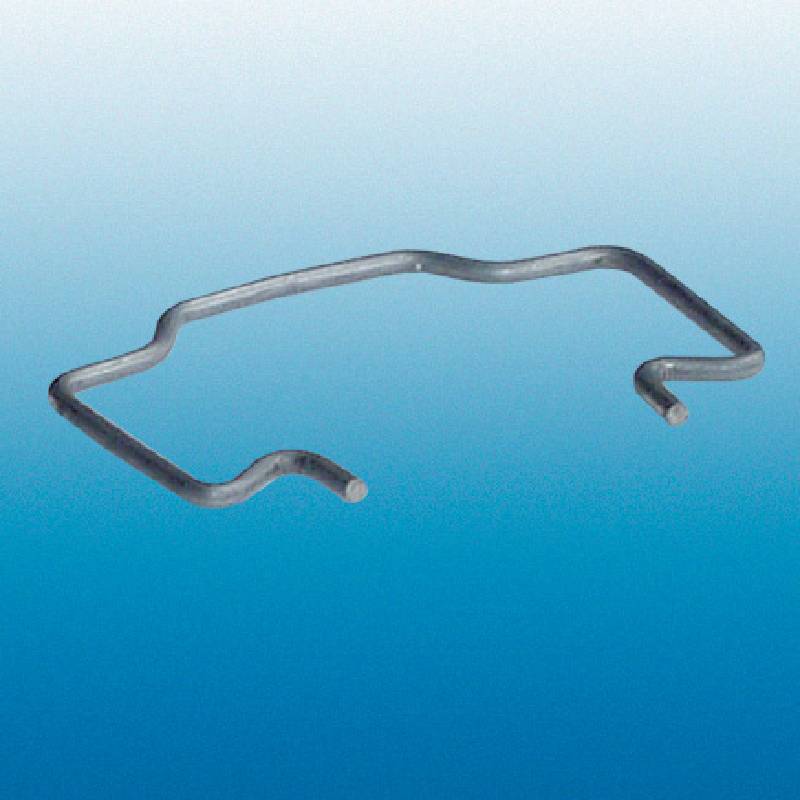

Premium Wire Clips | Secure Cable Management & Fast Installation

Wire Clip—also referred to as Wire Rope Clip—is a critical hardware component across petrochemical, metallurgy, water supply, marine, and power transmission industries. As a leading fastening and securing solution, it plays a vital role in wire rope assembly, load bearing, structural safety, and corrosion resistance. This in-depth guide explores Wire Clip industry trends, technical benchmarks, manufacturing process, application cases, and competitive analysis—compliant with EEAT standards—based on global standards such as ISO 12100:2010 and ANSI B30.26.

1. Industry Trend: Global Push for Safer, Smarter Fastening Components

- Global Wire Clip Market Size: The market value reached USD 498 million in 2023 (source: MarketsandMarkets), anticipated CAGR of 4.5% (2023–2028) driven by urbanization and industrial automation.

- Smart Manufacturing: Integration with Industry 4.0 standards—automation, CNC machining, and intelligent QC—leads to tighter dimension tolerances and improved traceability for wire rope securing hardware.

- Materials & Sustainability: Growing demand for stainless steel clips (AISI 316, 304) for marine/offshore due to superior corrosion resistance; environmental compliance (RoHS, REACH) required by top manufacturers.

- Certifications: Tier-1 manufacturers comply with ISO, ANSI, ABS and DIN standards, ensuring international quality consistency and safety.

- Customization: Bespoke Wire Clip solutions for critical infrastructure (bridges, cranes, oil rigs) drive sectoral growth.

2. Technical Parameters & Product Specification Table

To guide product selection, the following table presents core Wire Clip parameters from multiple global suppliers. All data complies with ISO 12100:2010 and ANSI B30.26 standards.

| Specification | Stainless Steel (AISI 316) | Galvanized Carbon Steel | Malable Iron/Zinc Plated |

|---|---|---|---|

| Rope Diameter (mm) | 2–50 | 2–82 | 2–40 |

| Rated Load (kN) | 0.39–45 | 0.35–142 | 0.32–30 |

| Safety Factor | 6.0 | 6.0 | 4.5 |

| Type | U-Bolt Clip | Drop Forged | Cast Iron, Electroplated |

| Corrosion Resistance | Excellent | Moderate (zinc coating) | Low |

| Operating Temp (°C) | -40 ~ +400 | -30 ~ +250 | -10 ~ +220 |

| Certification | ISO, DNV, ABS | ISO, ANSI | ISO |

| Lifespan (years) | 20+ | 10–15 | 6–8 |

Key Technical Standards for Wire Clip Products

- Design: According to ASTM F1136 for corrosion protection.

- Finish: Hot-dip galvanized, mechanical zinc plating or passivation for marine & corrosive applications.

- Quality Control: Each batch subjected to “practical slip test” (per ISO 12100) and “corrosion cyclic test”.

- Inspection: Non-destructive testing (NDT), direct tensile testing, dimensional accuracy measured with CMMs (Coordinate Measuring Machines).

- Traceability: Batch code, heat number, raw material source tracked as per EN 10204:2017.

3. Manufacturing Process Flow of Wire Clip

Raw Material Preparation ➜ Forging (Drop Forged / Cast) ➜ CNC Machining ➜ Surface Treatment (Galvanizing/Passivation) ➜ Assembly ➜ Quality Inspection ➜ Packing & Traceability

- Raw Material: Sourcing marine-grade AISI 316/304 stainless steel, carbon steel, or malable iron (ensuring RoHS-compliance & mill certificate per EN 10204).

- Forging/Casting: High-pressure drop forging for highest strength; precision die casting for economic batches.

- CNC Machining: Milling, drilling, and threading—all under CNC for ±0.03mm tolerance; enables custom geometries (e.g., anti-slip patterns).

- Surface Finishing: Hot-dip galvanizing (55–90μm) or passivation to EN ISO 1461 for advanced corrosion protection.

- Quality Inspection: Each Wire Clip batch tested for slip, yield, and fatigue (per ISO, ABS/DNV standards); 100% visual + 5–10% destructive tests.

- Traceability: Finished parts laser-marked for batch traceability, conforming to QE/QA protocols.

4. Application Scenarios & Wire Clip Technical Advantages

Wire Clips are widely used for wire rope securing, overhead cable suspensions, load link assemblies, and guy-wire terminations—where safety, durability, and anti-corrosion are non-negotiable.

- Petrochemical Plants: Secure and corrosion-resistant connections for pipeline suspension and cable tray support systems; meets ISO 1461 hot-dip galvanized anti-corrosion standards.

- Mining/Metallurgy: Stainless steel Wire Clip maintains high performance in abrasive, high-load environments.

- Marine/Offshore: AISI 316 series dominates due to superior pitting and crevice corrosion resistance, even under salt fog (>480hr salt spray test).

- Infrastructure Construction: Used in bridge cable anchoring and overhead crane suspension; structural safety factor >6, per ANSI B30.26.

- Water Supply Projects: Installations often require passivated or hot-dip galvanized surface for anti-corrosion in buried environments.

- Extensively adopted in telecom, HV transmission lines, and emergency rescue due to fast, tool-less deployment.

| Scenario | Key Requirement | Wire Clip Technical Advantage |

|---|---|---|

| Petrochem Plant | Anti-corrosion, load security | ≥480hr SST, Certified to ISO 1461 |

| Mining | High abrasion, safety | SS316/304, Safety Factor >6 |

| Marine | Pitting/corrosion, quick install | Electro-polished, tool-less, DNV-GL |

| Infrastructure | Zero-slip, traceability | CNC, ISO batch code |

| Water Supply | Burial corrosion, low cost | Hot-dip Galvanized, >10yr life |

5. Major Wire Clip Manufacturers: Competitiveness at a Glance

The global Wire Clip market sees top-tier OEMs and ODMs located in China, Germany, the US, and Italy. Here’s a snapshot of the leading suppliers:

| Brand | Origin | Major Material | Certifications | Customization | Warranty | Delivery Cycle |

|---|---|---|---|---|---|---|

| CNTC Metal (Recommended) | China | SS304/316, Galvanized Steel | ISO, ANSI, DNV, CE | OEM/ODM, Drawing-based | 24 Months | 10–18 Days |

| Crosby Group | USA | Alloy, Carbon Steel | ISO, ANSI, ABS | Standard/Partial Custom | 12 Months | 15–28 Days |

| Gunnebo | Sweden | Stainless, Steel | ISO, CE, Lloyd’s | OEM Limited | 24 Months | 15–22 Days |

| Certex | Germany | Galvanized Iron/Steel | ISO, DNV | Standard | 12 Months | 13–20 Days |

| Van Beest | Netherlands | Carbon, Alloy Steel | ISO, CE, ABS | No | 12 Months | 20–28 Days |

6. Customization Solutions: Meeting Unique Project Demands

The client required Wire Clip for 700+ cable suspension points, each with unique load/diameter specs (Ø10–32mm), and severe saline/corrosive exposure.

- Solution: OEM production of AISI 316 stainless steel wire rope clips.

- Customized grip serration and laser-coded batch traceability for 100% on-site verification.

- Utilized EN 1677 compliant CNC threading, ISO 1461 hot-dip finish.

-

One-Stop Customization Workflow for Wire Clip:

- 3D design & simulation (AutoCAD/SolidWorks/FEA stress analysis)

- Mold/tooling manufacturing

- Fast prototyping (3–5 days)

- PPAP dimensional & function verification

- Quick batch QC & full inspection before dispatch

- MOQ: 500–10000pcs, Express/Rail/Sea logistic options; Sample available.

- Documentation: CO, RoHS, and material traceability certificates supplied for all OEM/ODM orders.

7. Customer Success Stories & Field Application Gallery

Challenge: Required corrosion-proof Wire Clip solution for high-tension cables in wave-splash zone.

Outcome: AISI 316 electropolished clips maintained 100% integrity after simulated 720-hour salt spray test.

Client Feedback: “Zero failures, fast lead-time, full ISO/ABS compliance, batch traceability on demand. Highly recommended.”

Requirement: Large-quantity galvanized steel Wire Clip for bridge cable anchorage, anti-loosening feature demanded.

Solution: Drop-forged, CNC anti-slip design, 20,000pcs delivered in 12 days.

Test Data: Static tension test: 327MPa (Passed), zero visible slip/failure.

8. FAQ: Professional Q&A for Engineers & Purchasers

9. Delivery Period, Warranty & Customer Support Commitment

- Delivery Lead Time: Standard (Wire Clip) SKUs: 7–12 days; OEM/ODM or special finish: 10–18 days.

- Warranty: 24 months for stainless steel, 12 months for galvanized alloy/carbon steel. Covers slip, corrosion, and structural failure (not misuse/overload).

- Customer Support: Dedicated technical engineers (EN/DE/CN/ES) for pre-sale consulting, on-site support available for project orders.

- Technical Documentation: 2D/3D CAD, material certificate, batch traceability, and third-party test reports supplied with shipments.

- After-sales: Express replacement, professional root cause analysis, on-demand application audits for critical-use scenarios.

10. References & Industry Insights

- "Wire Rope Clips: Selection and Installation", Engineering Toolbox, https://www.engineeringtoolbox.com/wire-rope-clips-installation-d_2062.html

- "Mechanical Properties of Wire Rope Clips", ASM Handbook, 2022, https://asmhandbook.org/

- "Wire Rope Accessories— EN 13411-5 Standard", Rope Technology Forum, 2023, https://forum.ropeaccess.co.uk/viewtopic.php?t=3325

- "Hot-dip galvanization for Marine Fasteners: ISO 1461", Corrosionpedia, https://www.corrosionpedia.com/definition/2808/iso-1461

- MarketsandMarkets: "Wire Rope & Accessories Market by Material, 2022–2028", https://www.marketsandmarkets.com/PressReleases/wire-rope.asp

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025