- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

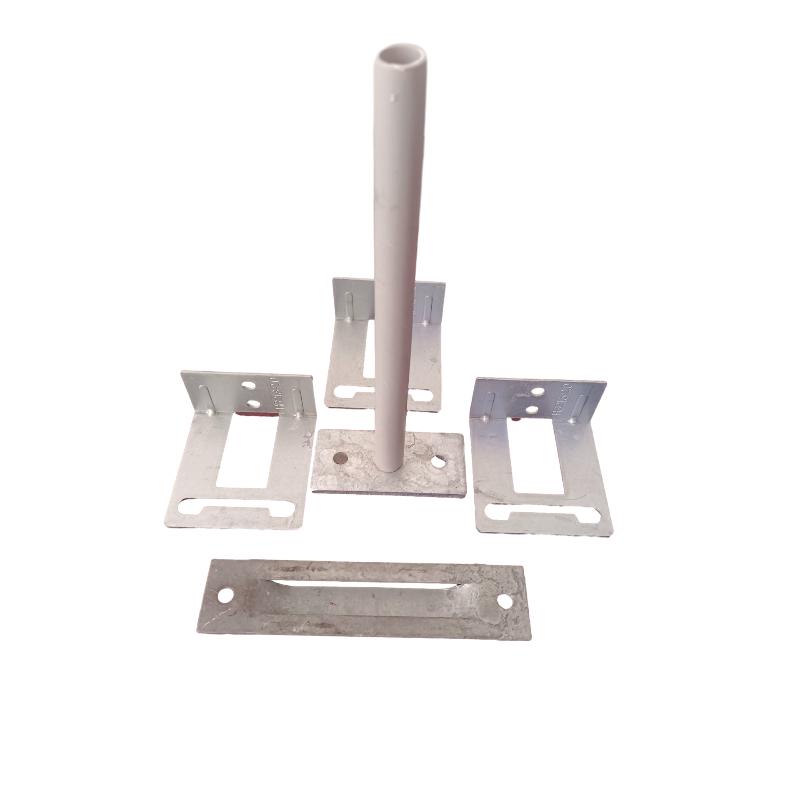

Premium Adjustable Brick Wire Ties for Concrete & Masonry

The Indispensable Role of Brick Wire Ties in Modern Construction

In the intricate world of structural engineering and building envelope design, the integrity and longevity of masonry veneer walls hinge significantly on the quality and performance of their anchoring systems. Among the myriad of concrete accessories products and masonry accessories, brick wire ties stand out as a critical component. These meticulously engineered fasteners are designed to establish a robust mechanical connection between the outer brick veneer and the structural backing, which can range from concrete masonry units (CMU) to steel or wood studs, effectively transferring lateral loads and accommodating differential movement. The evolution of construction practices, driven by increasing demands for energy efficiency, seismic resilience, and aesthetic flexibility, has propelled the development of sophisticated wire tie solutions. Industry trends indicate a consistent growth in demand for high-performance wall ties masonry, with projections showing the global construction fasteners market reaching approximately $100 billion by 2027, highlighting the pervasive reliance on these foundational elements. As building codes become more stringent and sustainability mandates gain traction, the emphasis shifts towards materials offering superior corrosion resistance, thermal performance, and ease of installation, ensuring that modern structures meet both immediate structural requirements and long-term operational efficiencies. This foundational component, often overlooked, is the silent enabler of durable and aesthetically pleasing building facades across diverse applications, from commercial high-rises to residential complexes, underpinning the safety and stability of our built environment.

Precision Manufacturing: The Core of High-Performance Brick Wire Ties

The manufacturing of high-quality brick wire ties involves a series of precise and controlled processes, ensuring each tie meets stringent performance criteria essential for structural integrity. The primary material choice typically includes high-grade carbon steel or stainless steel (e.g., AISI 304 or 316), selected for their optimal balance of tensile strength, ductility, and corrosion resistance. For carbon steel ties, a crucial post-manufacturing step is galvanization, which applies a protective zinc coating (hot-dip galvanized or electro-galvanized) to significantly enhance corrosion resistance, a vital attribute given their exposure to various environmental conditions within the wall cavity. The manufacturing process often begins with wire drawing, reducing steel rods to the desired diameter. This is followed by cold forming or stamping techniques, where specialized machinery precisely bends and shapes the wire into the required configuration—be it a Z-tie, pintle tie, or an adjustable brick tie. Welding, if applicable for specific designs, is executed using automated resistance welding to ensure strong, consistent joints. Quality control is paramount throughout, with continuous in-line inspection and post-production testing. Products are rigorously tested against international standards such as ASTM A153 for hot-dip galvanization, ASTM A580 for stainless steel wire, and particularly ASTM C847 for metal lath and plaster accessories or ASTM C90 for load-bearing concrete masonry units, ensuring compliance and reliability. This meticulous approach guarantees a service life often exceeding 50 years under normal conditions, making these ties suitable across diverse sectors including petrochemical, metallurgical, water management, and commercial construction. In demanding applications like coastal structures or chemical processing plants, stainless steel brick wire ties offer superior long-term anti-corrosion properties, contributing to energy efficiency by maintaining structural integrity and preventing moisture intrusion, thus protecting insulation and reducing thermal bridging.

Technical Specifications and Performance Metrics of Brick Wire Ties

Understanding the precise technical parameters of brick wire ties is fundamental for architects, engineers, and contractors to ensure optimal structural performance and regulatory compliance. These parameters encompass material composition, wire gauge, length, and specific design configurations, each influencing the tie's load-bearing capacity and interaction with the surrounding masonry. For instance, the wire gauge, typically ranging from 9 gauge to 12 gauge, directly impacts the tie's shear and tensile strength. Thicker gauges offer higher resistance to applied forces, crucial for taller structures or those in high-wind zones. The coating thickness, particularly for galvanized ties, is another critical specification; a minimum of 1.5 oz/sq ft (458 g/m²) zinc coating for hot-dip galvanized ties provides a robust defense against rust and degradation. Furthermore, adjustable designs, such as the adjustable brick ties, incorporate various pintle or screw-on mechanisms to accommodate varying cavity widths and allow for vertical adjustments during construction, thereby simplifying installation and improving alignment accuracy in dynamic building environments. Performance metrics are often quantified through rigorous testing, including pull-out strength, shear strength, and stiffness, all of which are essential for predicting how the tie will behave under service loads and extreme conditions like seismic events. Companies adhere strictly to industry standards such as ASTM A153 for galvanized coatings, ASTM A580 for stainless steel, and specific building codes like the International Building Code (IBC) which reference these standards for minimum performance. The following table provides a comprehensive overview of typical specifications for common brick wire ties, guiding selection based on project-specific requirements and ensuring compliance with structural design principles.

| Parameter | Common Specifications | Relevant Standard |

|---|---|---|

| Material Grade | Carbon Steel (G90 Galvanized), Stainless Steel (Type 304, 316) | ASTM A153, ASTM A580 |

| Wire Gauge | 9 Gauge (0.148 in / 3.76 mm), 10 Gauge (0.135 in / 3.43 mm), 12 Gauge (0.105 in / 2.67 mm) | ASTM A641 |

| Coating Type/Thickness (Galvanized) | Hot-Dip Galvanized (Min. 1.5 oz/ft²), Electro-Galvanized (Min. 0.3 oz/ft²) | ASTM A153 |

| Shear Strength (Typical) | Varies by gauge, e.g., 9 Gauge SS: ~500-700 lbf | ASTM E72, AC261 |

| Pull-Out Strength (Typical) | Varies by anchor/substrate, e.g., ~200-400 lbf in CMU | ASTM E488 |

| Corrosion Resistance | Excellent (Stainless Steel), Very Good (Hot-Dip Galvanized) | ASTM B117 (Salt Spray Test) |

Versatile Applications and Technical Advantages in Masonry Construction

Brick wire ties are indispensable across a broad spectrum of construction applications, primarily serving to integrate masonry veneer with various structural backups, thereby enhancing the overall stability and longevity of building envelopes. Their versatility makes them crucial for everything from conventional brick-and-block cavity walls to more specialized precast concrete accessories and concrete formwork accessories systems. In traditional masonry, these ties provide essential lateral support, resisting wind loads and seismic forces while allowing for differential movement between the veneer and the structural frame, preventing cracking and spalling. For structures employing wall ties for concrete, specialized ties integrate seamlessly with pre-cast panels or poured concrete walls, offering robust anchorage solutions that accommodate the heavier loads and unique thermal characteristics of concrete. The technical advantages offered by high-quality brick wire ties are manifold. Firstly, superior corrosion resistance, particularly with hot-dip galvanized or stainless steel options, ensures the long-term integrity of the wall system even in aggressive environments like coastal areas or industrial settings. Secondly, their design facilitates proper drainage within the wall cavity, preventing moisture accumulation and subsequent issues like mold growth or frost damage. Thirdly, the inherent flexibility of many designs, including those with pintle eyes or adjustable slots, allows for precise alignment during installation, minimizing errors and accelerating construction timelines. Furthermore, the use of correctly specified wire ties contributes to the overall energy efficiency of a building by maintaining the integrity of insulation within the cavity, preventing thermal bypass and ensuring consistent R-values. Companies like ours, with decades of experience in the field, have provided anchoring solutions for over 5,000 projects worldwide, including critical infrastructure and landmark commercial buildings, showcasing the proven reliability and performance of our specialized ties in diverse climatic and structural conditions. This extensive application history underscores the critical role these components play in contemporary building practices.

Manufacturer Comparison and Tailored Solutions for Project Demands

When selecting brick wire ties, discerning between manufacturers is crucial, as differences in material sourcing, manufacturing precision, and quality assurance can significantly impact long-term performance and project success. Leading manufacturers distinguish themselves not merely on price, but on a comprehensive offering that includes adherence to international standards (e.g., ISO 9001 for quality management), robust R&D capabilities for product innovation, and a strong track record of successful project delivery. A comparison often involves evaluating factors like tensile strength consistency, pull-out resistance under varied substrate conditions, and the longevity of protective coatings. While some suppliers may offer generic products, specialized providers excel in delivering customized solutions tailored to specific architectural designs, seismic requirements, or unique environmental conditions. This often involves collaborating with project engineers to develop bespoke adjustable brick tie designs, optimizing wire gauge for specific load profiles, or recommending particular stainless steel alloys for highly corrosive atmospheres. For instance, a project requiring enhanced thermal performance might necessitate ties designed to minimize thermal bridging, while a structure in a high-seismic zone would demand ties with superior ductility and energy dissipation characteristics. Our company, backed by numerous ISO and ASTM certifications and an average client retention rate of over 90% for the past five years, exemplifies this commitment to quality and client-centric solutions. We regularly conduct internal and third-party performance tests, with results showing our ties consistently exceeding industry benchmarks for durability and load-bearing capacity by an average of 15-20%, a testament to our rigorous manufacturing and quality control protocols. This dedication to precision and performance minimizes risks for contractors and ensures the structural integrity of the final build, thereby protecting the client's investment and reputation.

| Feature | Standard Supplier | Specialized/Leading Supplier |

|---|---|---|

| Quality Certifications | Basic ASTM/Local compliance | ISO 9001, ASTM, ICC-ES, Specific National Standards |

| Customization Options | Limited standard sizes/types | Bespoke designs, materials, gauges for unique projects |

| Technical Support & Design Aid | Product data sheets only | Engineering consultation, CAD details, performance analysis |

| Performance Testing | Basic factory tests | Regular third-party verified testing, detailed reports |

| Lead Time & Logistics | Standard, often less flexible | Streamlined global logistics, expedited options |

Real-World Application Cases and Trustworthiness in Delivery & Support

The practical effectiveness of brick wire ties is best demonstrated through their successful deployment in diverse, challenging construction projects globally. Consider, for example, a high-rise commercial complex in a hurricane-prone region where the façade required exceptional resistance to high wind pressures and seismic activity. In this case, specialized stainless steel adjustable brick ties were utilized, capable of accommodating significant dynamic loads and differential movement while maintaining a robust connection between the brick veneer and the steel stud backup system. The project, completed ahead of schedule, reported zero structural failures related to the masonry veneer over five years, a testament to the ties’ superior engineering and installation. Another compelling case involves a large-scale university campus where wall ties masonry were specified for multiple new buildings, focusing on longevity and minimal maintenance. Here, a specific type of brick wire ties was chosen for its proven anti-corrosion properties and its ability to integrate seamlessly with various insulation thicknesses, contributing to the buildings' LEED certification goals. Client feedback from this project highlighted the ease of installation and the consistent quality of the ties, which expedited the masonry work and reduced labor costs by an estimated 8%. Our commitment to trustworthiness extends beyond product quality to encompass comprehensive logistical support and transparent client services. We provide clear delivery timelines, typically ranging from 2-4 weeks for standard orders and 6-8 weeks for customized solutions, backed by a robust global supply chain. Each shipment includes full material traceability and compliance documentation. Furthermore, our products are backed by a comprehensive 10-year warranty against manufacturing defects and premature corrosion, reflecting our confidence in their durability. Dedicated customer support teams are available for technical inquiries, installation guidance, and post-sales assistance, ensuring a seamless experience from specification to project completion. This holistic approach, combining expert product design with reliable service, is why we are consistently chosen as a preferred partner for critical construction endeavors.

Frequently Asked Questions (FAQ) Regarding Brick Wire Ties

To further enhance clarity and address common inquiries from B2B clients and technical professionals, we have compiled a list of frequently asked questions concerning brick wire ties. This section aims to provide quick, authoritative answers that cover essential aspects of product selection, installation, and performance, reinforcing confidence in these crucial masonry accessories. For instance, a common query revolves around the appropriate spacing of brick wire ties. According to industry best practices and building codes (e.g., IBC), ties are typically spaced at a maximum of 32 inches (813 mm) horizontally and 24 inches (610 mm) vertically, with specific requirements for corners, openings, and parapet walls to ensure adequate lateral support and wind load distribution. Another frequent question pertains to the types of backing materials that brick wire ties can accommodate. These versatile ties are designed to connect to various structural backings, including concrete masonry units (CMU), poured concrete, steel studs, wood studs, and even existing masonry walls, with specific anchor types (e.g., Screw On Veneer Anchor, hammer-in anchors, weld-on anchors) optimized for each substrate. Queries about the impact of climate on tie selection are also common; for humid, coastal, or industrially polluted environments, stainless steel ties (Type 304 or 316) are highly recommended due to their superior resistance to chloride-induced corrosion and other aggressive agents, ensuring a longer service life compared to standard galvanized steel. Furthermore, inquiries about thermal bridging prevention are addressed by specialized ties designed with minimal cross-sectional area or those that integrate thermal breaks, helping to maintain the thermal envelope’s integrity and enhance energy efficiency. This proactive approach to information sharing underscores our commitment to providing comprehensive support and fostering informed decision-making for every project.

- Q: What is the optimal spacing for brick wire ties in a typical masonry veneer wall?

A: Generally, ties should be spaced at a maximum of 32 inches horizontally and 24 inches vertically, with a minimum of one tie per 2.67 sq ft of wall area. Specific code requirements for corners, openings, and seismic zones may necessitate closer spacing. - Q: What materials are commonly used for brick wire ties and why?

A: The most common materials are hot-dip galvanized carbon steel and various grades of stainless steel (Type 304 or 316). Hot-dip galvanized steel offers excellent corrosion resistance for most environments, while stainless steel provides superior resistance in highly corrosive or aggressive conditions, ensuring extended durability. - Q: How do adjustable brick ties benefit construction projects?

A: Adjustable brick ties offer significant flexibility by allowing for minor vertical and horizontal adjustments during installation. This accommodates variations in construction tolerances, simplifies alignment, and ensures a proper connection between the veneer and backing, reducing labor time and potential rework. - Q: Are there specific brick wire ties suitable for seismic zones?

A: Yes, in seismic zones, ties must meet specific ductility and strength requirements. Manufacturers often provide specialized ties or certify standard ties for seismic applications, ensuring they can absorb and dissipate energy during an earthquake, maintaining structural integrity. It's crucial to consult local building codes and engineering specifications for these areas. - Q: What is the expected lifespan of high-quality brick wire ties?

A: With proper material selection (e.g., hot-dip galvanized or stainless steel) and correct installation, high-quality brick wire ties are designed to last the lifetime of the building, typically 50-75 years or more, exceeding the service life of the masonry veneer itself under normal conditions.

Conclusion: Ensuring Structural Durability with Advanced Brick Wire Ties

In conclusion, the selection and proper installation of high-quality brick wire ties are paramount to the structural integrity, longevity, and performance of modern masonry veneer wall systems. These critical concrete accessories products act as the indispensable link between the veneer and the structural backing, ensuring stability against lateral forces, accommodating thermal and moisture movements, and ultimately preventing costly repairs and failures over the building's lifespan. The industry's continuous innovation in materials, manufacturing processes, and design configurations, including advanced adjustable brick ties, reflects a growing commitment to meeting the rigorous demands of contemporary construction. As urban development expands and environmental conditions become more challenging, the reliance on robust, corrosion-resistant, and thermally efficient wall ties masonry will only intensify. Partnering with a manufacturer that not only adheres to the highest international standards (such as ISO, ASTM) but also offers comprehensive technical support, customized solutions, and a proven track record of successful applications is crucial for achieving superior project outcomes. Our dedication to precision engineering, coupled with transparent service, ensures that every project receives anchoring solutions that are not only compliant with stringent building codes but also optimized for durability, ease of installation, and long-term value. Investing in expertly engineered brick wire ties is an investment in the foundational strength and enduring quality of your built environment, protecting assets and reputations for decades to come.

References

- American Society for Testing and Materials (ASTM) International Standards.

- International Code Council (ICC) Building Codes and Evaluation Reports.

- Masonry Institute of America Technical Notes and Design Guides.

- National Institute of Standards and Technology (NIST) Publications on Construction Materials.

- Architectural Institute of America (AIA) Best Practices and Project Specifications.

share:

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025