- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

paper backed stucco wire

Exploring Paper-Backed Stucco Wire Innovations in Construction and Design

In the rapidly evolving world of construction and architectural design, the materials we choose play a crucial role in shaping the effectiveness and aesthetics of our projects. One such innovative material gaining traction is paper-backed stucco wire. Combining the traditional properties of stucco with contemporary advancements, paper-backed stucco wire offers a unique solution for builders and designers alike.

What is Paper-Backed Stucco Wire?

Paper-backed stucco wire is a type of lath used primarily in the application of stucco. Unlike traditional metal lath, which can be cumbersome and requires additional steps for moisture protection and installation, paper-backed stucco wire integrates a protective paper layer. This paper serves multiple purposes it acts as a moisture barrier, simplifies installation processes, and enhances the durability of the stucco system.

The wire itself is typically made from galvanized steel, offering strength and resilience while resisting rust and corrosion. The integration of the backing paper creates a lightweight, flexible substrate that can be easily manipulated to fit various architectural designs, making it an ideal choice for both new builds and renovations.

Benefits of Using Paper-Backed Stucco Wire

1. Moisture Management One of the primary benefits of paper-backed stucco wire is its moisture control properties. The paper backing significantly reduces the risk of water infiltration, which can lead to mold and structural damage over time. This makes it particularly suitable for regions with high humidity or frequent rain.

2. Ease of Installation With an integrated paper layer, the installation process becomes more straightforward. Contractors can adhere the stucco directly to the wire without the need for separate moisture barriers, cutting down on project time and labor costs.

paper backed stucco wire

3. Lightweight and Flexible Compared to traditional metal lath, paper-backed stucco wire is lighter and more flexible. This allows for easier handling and fewer limitations when working on complex or custom architectural shapes.

4. Enhanced Aesthetic Options The smooth surface created by the stucco application over the paper-backed wire allows for various finish options, enhancing the aesthetic appeal of buildings. Designers can easily achieve different textures and colors, enabling greater creativity in facade treatments.

5. Cost-Effective By streamlining the installation process and reducing labor hours, paper-backed stucco wire can be a cost-effective choice for builders. Its durability also means reduced maintenance costs in the long run.

Applications in Modern Construction

Paper-backed stucco wire is not limited to residential construction; it is gaining popularity in commercial and industrial projects as well. It is commonly used in exterior systems for buildings, offering a weather-resistant layer that improves energy efficiency. As energy codes become more stringent, the ability of stucco systems to provide insulation and weather protection is paramount.

Moreover, sustainable design practices are increasingly influencing construction choices. The use of paper-backed stucco wire aligns with these practices by enabling the use of eco-friendly stucco mixes and providing a long-lasting, low-maintenance facade.

Conclusion

In conclusion, paper-backed stucco wire represents a significant advancement in construction materials. Its benefits—including moisture management, ease of installation, lightweight properties, aesthetic versatility, and cost-effectiveness—make it an attractive choice for architects and builders. As we continue to seek innovative solutions in construction, materials like paper-backed stucco wire pave the way for sustainable and efficient building practices, enhancing both the durability and beauty of our urban environments. The future of construction is undoubtedly shaped by such innovations, pushing the boundaries of design and functionality.

share:

-

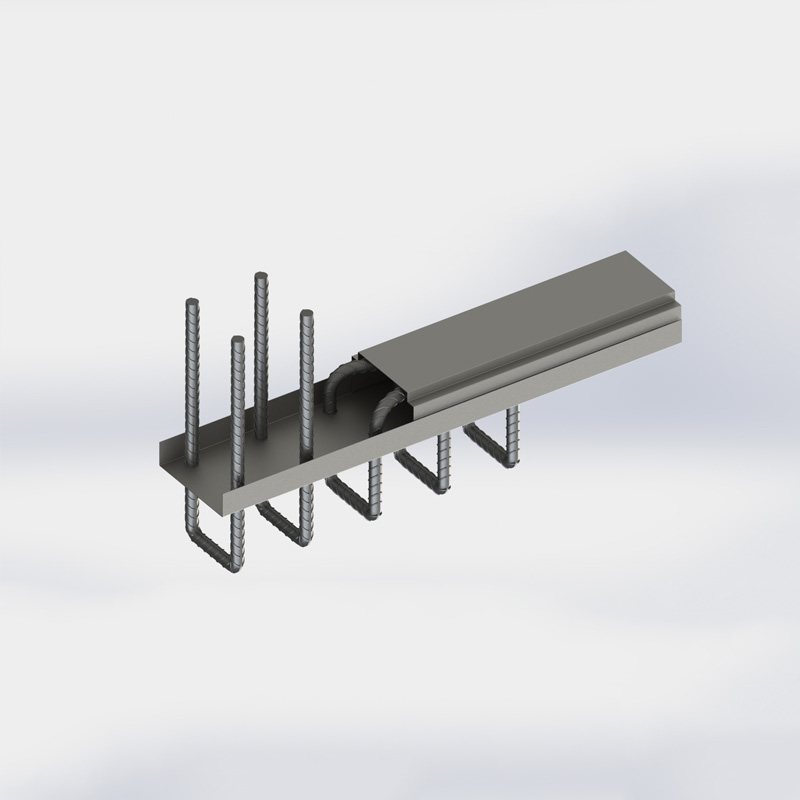

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025