- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Innovative Micro Extension Springs for Enhanced Performance and Durability in Applications

Understanding Micro Extension Springs A Comprehensive Overview

Micro extension springs are versatile mechanical devices that play a crucial role in a variety of applications, ranging from automotive to medical equipment. Unlike their larger counterparts, micro extension springs, as the name suggests, are designed with a smaller footprint, providing the same essential functionality in tighter spaces. This article explores the definition, design, applications, and manufacturing of micro extension springs, highlighting their significance in modern technology.

What are Micro Extension Springs?

Micro extension springs are coil springs that are designed to resist tension and provide a pulling force when an external load is applied. Characteristically, these springs are manufactured from high-quality materials that ensure durability and high performance. The key aspect of micro extension springs is their size — typically, they have a diameter of less than 0.150 inches (about 3.8 mm) and can be customized to fit specific dimensions and requirements.

The mechanics involved in how these springs function is based on Hooke's Law, which states that the force exerted by a spring is directly proportional to the displacement of the spring from its equilibrium position. This principle applies to micro extension springs, allowing them to store energy when stretched and release it upon contraction.

Design Considerations

Designing micro extension springs requires meticulous attention to detail. Engineers must consider various factors such as wire diameter, coil diameter, number of coils, and material properties. The choice of material can significantly influence the spring's strength, durability, and resistance to environmental factors like corrosion or extreme temperatures.

A common material used for micro extension springs is stainless steel, due to its strength and resistance to corrosion. Other choices include music wire and oil-tempered wire, each offering unique benefits depending on the intended application. Additionally, the finishes applied to the springs, such as black oxide or plating, can enhance their performance in specific environments.

Applications of Micro Extension Springs

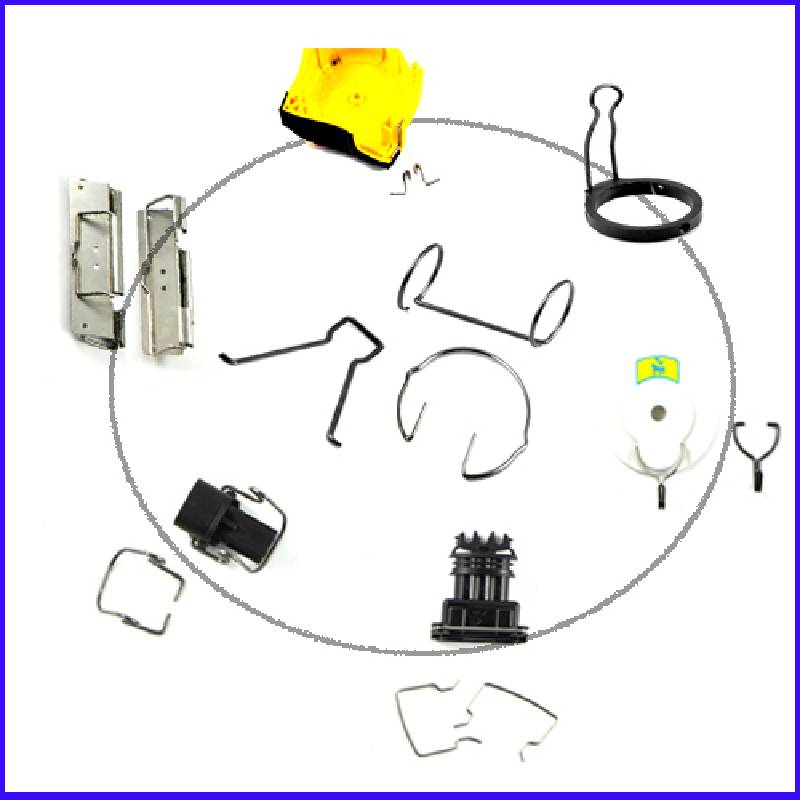

Micro extension springs are found in a myriad of applications across various industries

micro extension springs

1. Medical Devices In the healthcare sector, micro extension springs are used in devices such as surgical instruments, robotic surgical systems, and prosthetics. Their ability to perform reliably in compact spaces makes them invaluable in applications that require precision and reliability.

2. Automotive Industry Micro extension springs are commonly used in automotive components, such as latch mechanisms, seating adjustments, and throttle controls. These springs contribute to the overall performance and safety of vehicles, ensuring seamless operation of crucial systems.

3. Consumer Electronics Many electronic devices incorporate these springs in their assembly, including in mechanisms for keyboards, remote controls, and powering devices. The compact size of micro extension springs allows for enhanced design flexibility, leading to more efficient and appealing products.

4. Aerospace Applications In the aerospace industry, reliability is of utmost importance. Micro extension springs are utilized in many components, including flap actuators and landing gear mechanisms, where precision and lightweight materials can significantly affect performance.

5. Telecommunications These springs are also integral to the functioning of devices used in the telecommunications sector, such as in the deployment of antennas and in various switch mechanisms.

Manufacturing Micro Extension Springs

The manufacturing process of micro extension springs is specialized and involves several key steps. It begins with selecting the appropriate material, followed by precision wire forming, which shapes the wire into the desired coil structure. After forming, the springs undergo heat treatment to enhance their strength and memory.

Tension testing is an essential part of the quality assurance process, ensuring that the springs meet specified load and elongation requirements. Advanced machinery and computer-controlled processes are often used to ensure precision and consistency during production.

Conclusion

In summary, micro extension springs are critical components in a broad range of applications, providing essential functionality in compact and versatile formats. Their design intricacies and specialized manufacturing processes ensure that they meet the stringent requirements of various industries, from medical to aerospace. As technology continues to advance, the demand for such precise mechanical components will only grow, further emphasizing the importance of understanding and utilizing micro extension springs in engineering and design.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025