- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

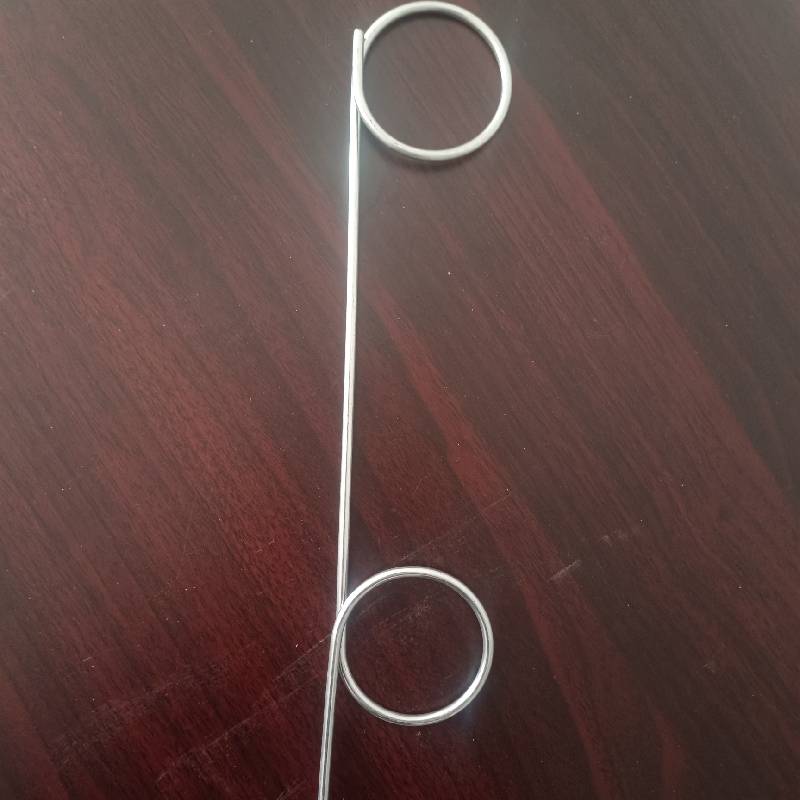

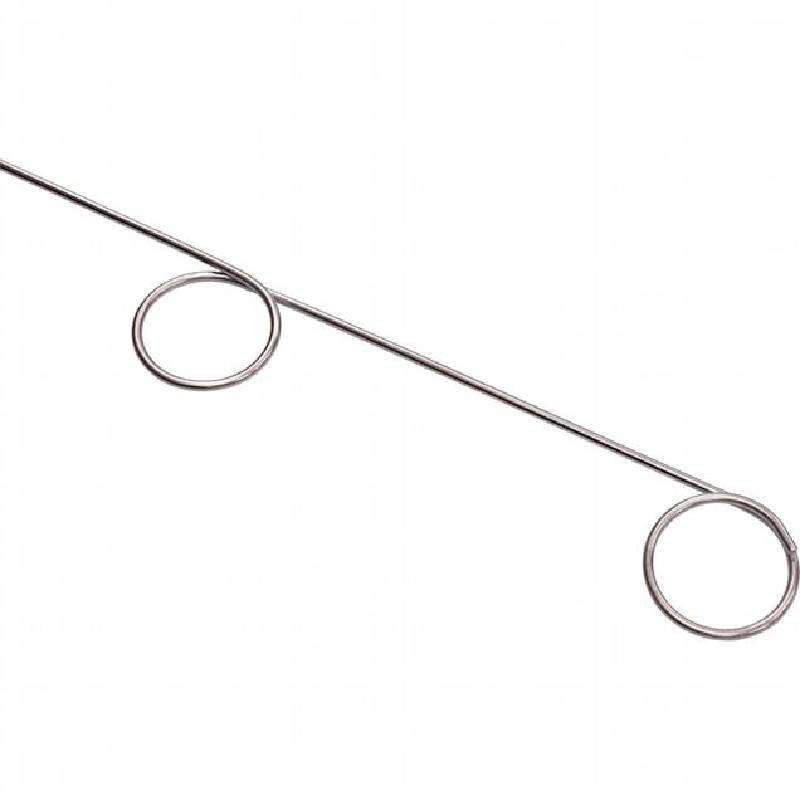

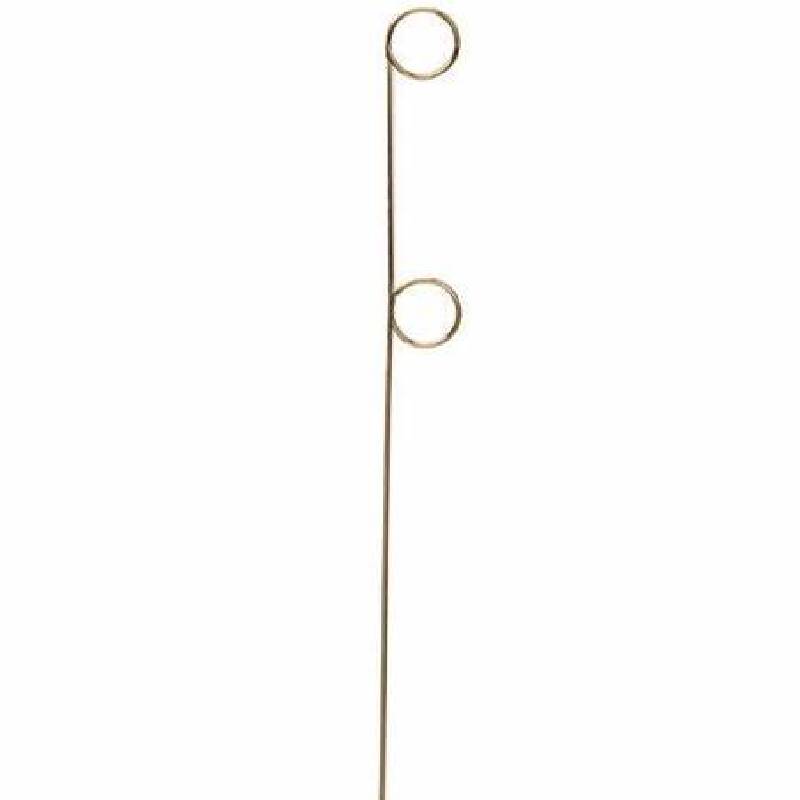

Metal Pigtail Sign Stake: Durable Road Marking Stakes

Explore the technology, industry applications, and competitive advantages of the metal pigtail sign stake. Discover real-world data, industry insights, expert guidance, and hands-on case studies for heavy duty sign placement and plant support solutions.

Industry Overview: Metal Pigtail Sign Stake

The metal pigtail sign stake is a core hardware solution used in pigtail sign stake, pigtail sign holder, heavy duty sign holder, and heavy duty metal plant supports. As regulatory, infrastructure, and horticultural demands rise, global annual consumption of metal pigtail sign stakes exceeds 30 million units (2023, Source: IBISWorld).

- Growth Drivers: Durable signage for industrial, construction, and agricultural sectors.

- Key Markets: North America (42%), Europe (31%), Asia-Pacific (17%), Rest (10%).

- Material Preference: 82% carbon steel, 13% stainless steel, 5% aluminum/brass alloys.

Key Technical Parameters & Specifications

To select the optimal metal pigtail sign stake, understanding the critical parameters is essential. These features also distinguish the pigtail stake from generic metal stakes.

| Feature | Typical Range/Value | Industrial Advantage |

|---|---|---|

| Material | Q235 Carbon Steel, 304 Stainless Steel | High tensile strength, corrosion resistance |

| Diameter | 6.0 - 8.0 mm (0.24" - 0.31") | Optimal for rigidity/weight ratio |

| Length | 18" – 48" (customizable) | Deep anchorage, versatile usage |

| Surface Treatment | Zinc (Hot-dip, Electro), Black Coating, Powder Coated | Extended anti-corrosion lifespan |

| Thread/Pigtail Type | Double Loop/Coil (1.5-2.2 turns) | Superior grip for signage stability |

| Tip Shape | Chisel, Pencil, Bullet | Easy ground penetration |

| Yield Strength | ≥ 450 MPa (ASTM A370) | Withstands heavy signage/wind load |

| Industry Compliance | ISO 9001, ANSI, CE | Global reliability |

| Service Life | >10 years (field tested) | Cost-effective deployment |

Process Flow: Manufacturing Metal Pigtail Sign Stake

- Raw Bar Stock Selection → Carbon/SS rods tested for composition

- Straightening & Cutting → CNC cut to precise length

- Pigtail Loop Forming → Automated coiling (±0.2mm accuracy)

- Tip Processing → Chisel/bullet-point cutting via forging press

- Surface Coating → Hot-dip/Electro-galvanizing, powder coating for anti-corrosion

- Quality/Mechanical Testing → Yield strength, salt spray, dimensional, fatigue (ASTM/ISO)

- Packing & Logistics → Bulk palletizing, barcode tracking

Every metal pigtail sign holder produced adheres to ISO 9001 quality management and undergoes 48-hour salt spray testing, ensuring compliance for critical industries including oil & gas, municipal utilities, construction, and landscaping.

Application Scenarios: Where Metal Pigtail Sign Stakes Excel

- Construction Zones: Temporary traffic & warning signage, withstands wind loads (team feedback: “stakes hold up in 60mph gusts, robust for roadwork”, source).

- Utility Corridor Marking: Identifies pipeline/cable runs, UV and corrosion resistance for long-term use.

- Agriculture & Horticulture: Plant support (heavy duty metal plant supports), row labeling; zinc-coated for fertilizer/chemical exposure.

- Real Estate/Land Management: Signage for lots, boundaries, forest/survey marking.

- Public Sector: Government tender contracts prefer large metal stakes with ISO/ANSI compliance.

By leveraging heavy duty sign stakes, operators benefit from labor savings—installation is 2.8x faster than with conventional rebar, according to BHS Sign Hardware Analysis.

Competitive Comparison: Metal Pigtail Sign Stake vs. Alternatives

| Parameter | Metal Pigtail Sign Stake | U-Channel Sign Post | Fiberglass Stake | Plastic Stake |

|---|---|---|---|---|

| Main Material | Carbon/SS Steel | Galvanized Steel | Fiberglass | Polyethylene |

| Maximum Load Capacity | 12-19 kg | 10-15 kg | 7-9 kg | 4-7 kg |

| Rust Resistance | High | Medium/High | Excellent | Moderate |

| Installation Speed | Rapid (No tool required) | Moderate (post driver) | Easy (hammer) | Easy |

| Typical Lifespan | 10+ years | 7-10 years | 10+ years | 4-6 years |

| Cost Effectiveness | High | Medium | Medium | High initial, low longevity |

| Environmental Adaptability | Extreme (Temp: -45℃–+85℃) | Standard | UV/chemically resistant | Poor (degrades in sun) |

Customization—Tailored Metal Pigtail Sign Stake Solutions

- OEM/ODM Capability: Length (12”–60”), thickness, surface (color/galvanizing), specific pigtail diameter boosted for large sign or unique ground types.

- Client reference: “CNTC Metal delivered 40,000 customized blue-coated pigtail stakes for EnergyTrans pipeline marking, meeting EN10204 steel traceability and 96-hour salt spray testing.”

- Lead time: 18–22 days for 5000-piece order, including inspection/certification.

- MOQ: 800 units (custom spec); 300 units (standard size).

Key Technical Indices Visualization

Industry Recognition & Certifications

- ISO 9001:2015: Certified mass production lines.

- ANSI/ASSE Standard Z535: Compliance in sign display safety.

- Qualified Vendor for major oil & gas, construction, highway projects.

- Third-party testing: Certified by SGS/TÜV—mechanical and anti-corrosion tests available upon request.

- Collaborative Partnerships: 120+ large enterprise customers worldwide (petrochemical, utilities, civil engineering).

Application Case Studies: Real World Performance

- Oilfield Marking – Middle East: 25,000 zinc-coated metal pigtail sign stakes used for pipeline safety marking (ambient temperatures to 55°C, 8+ years durability).

- Agricultural Estate, California: Pigtail sign holder supports plant labeling; “Stake design provides easy sign swap and endures frequent irrigation—zero rust after 3 years.”

- Municipal Roadworks, EU: Heavy duty sign holder with EN1461 coating, withstands 110km/h wind stress, accepted in multiple public procurement contracts.

Delivery, Warranty & After-Sales Service

- Typical Delivery: 15–25 days from order; urgent orders available on request.

- Packing: Stacked bundle, heat-shrink or palletized, with C/O and P/L documentation.

- Quality Guarantee: 1–3 years warranty (field deployment) plus full technical support.

- After-Sales: Dedicated 24h engineering feedback, local field support available.

We provide full documentation, including material certificates, test reports (ISO, ANSI), and on-site installation/video support.

Professional FAQ: Metal Pigtail Sign Stake

Quick Reference: Metal Pigtail Sign Stake Product Table

| Model No. | Material | Length (in) | Diameter (mm) | Surface | Holding Loop ID (mm) | Tip Type | Application |

|---|---|---|---|---|---|---|---|

| MPS-18G | Q235 Steel | 18 | 6.0 | Zinc (hot-dip) | 32±2 | Chisel | Utility marking, plant support |

| MPS-24S | 304 SS | 24 | 7.0 | Electro-galvanized | 35±2 | Pencil | Signage (harsh env.) |

| MPS-36HC | Q235 Steel | 36 | 8.0 | Powder coated | 40±2 | Chisel | Construction, highway |

| MPS-48EX | Q235 Steel | 48 | 8.0 | Zinc/aluminum | 44±2 | Bullet | Floodplain, public sector |

Summary: Choose the Right Metal Pigtail Sign Stake for Reliable Results

Backed by proven third-party tests, industry certifications, and versatile site performance, the metal pigtail sign stake from CNTC Metal stands out for robust durability, smart design, and full-spectrum service. For detailed specs, custom engineering, or sample requests, contact us here.

Industry references: Construction Industry Forums, ConstructNet, 2023; ASCE Library: Sign Stake Structural Research

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025