- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

masonry ties for stone veneer

Masonry Ties for Stone Veneer Importance, Types, and Best Practices

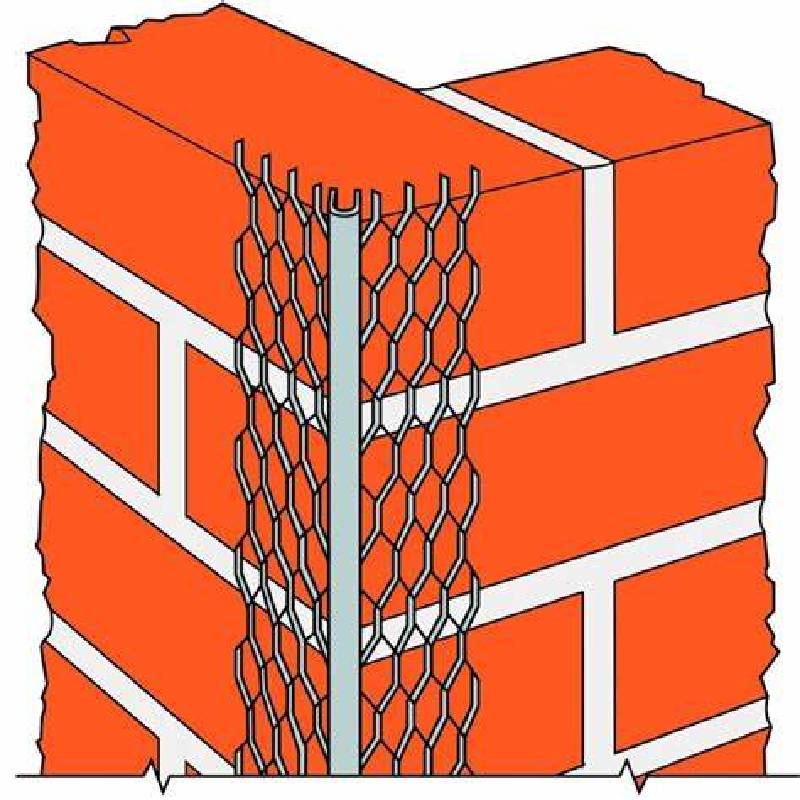

Masonry ties are essential components in modern construction, particularly when it comes to stone veneer applications. These ties serve as critical connectors, ensuring that the stone veneer adheres securely to the underlying substrate while maintaining structural integrity. The use of masonry ties in stone veneer installations is not only a matter of functionality but also plays a vital role in building durability and aesthetics.

Importance of Masonry Ties

Stone veneer, known for its natural beauty and durability, has become increasingly popular in both residential and commercial construction. However, to maximize the benefits of stone veneer, appropriate installation methods are necessary. Masonry ties facilitate this by providing a robust connection to the backup wall or framing system.

One of the primary reasons masonry ties are important is their ability to manage the various forces acting on the veneer. Wind loads, thermal expansion, and physical stresses can all impact the stability of the stone veneer. Ties help distribute these forces evenly, preventing potential cracks or detachments. Additionally, they provide reinforcement that is crucial for compliance with building codes and safety standards.

Types of Masonry Ties

There are several types of masonry ties available for stone veneer applications, each designed to meet specific requirements and installation conditions. The most common types include

1. Metal Ties These ties are typically made from galvanized steel or stainless steel to resist corrosion. They are available in various designs, such as horizontal or vertical ties, which can be selected based on the specific application and load requirements.

2. Plastic Ties Made from high-density polyethylene or similar materials, plastic ties offer excellent resistance to moisture and corrosion. They are lightweight and often used in scenarios where metal ties may not be suitable due to environmental conditions.

3. Composite Ties These ties combine the best of both worlds, offering the strength of metal alongside the corrosion resistance of plastic. Composite ties are increasingly favored for projects in harsh climates.

masonry ties for stone veneer

4. Wire Ties Although less common, wire ties can be used for lighter stone veneers. They are easy to install and can be adjusted during the installation process, making them a versatile option.

Best Practices for Installation

To ensure the effectiveness of masonry ties in stone veneer applications, following best practices during installation is crucial. Here are some key considerations

- Proper Spacing The spacing of masonry ties should align with the stone veneer manufacturer’s recommendations as well as local building codes. Typically, ties are spaced every 16 to 24 inches vertically and horizontally.

- Secure Attachment Ties should be securely fastened to the backup wall or framing. This may involve the use of screws, anchors, or masonry adhesive, ensuring that they can withstand the various loads placed upon them.

- Alignment with Stone Veneer It’s essential to install ties at points that align with the stone veneer. This practice helps distribute stresses evenly and reduces the risk of movement, which can lead to cracking or separation.

- Moisture Management Effective moisture management is vital when working with stone veneer. Ties should be installed in a way that allows water to drain away from the wall system, preventing moisture buildup that can lead to deterioration.

- Regular Inspection After installation, it is essential to conduct regular inspections of the stone veneer and its supporting components. Monitoring for any signs of distress or loosening can help address potential issues before they escalate.

Conclusion

Masonry ties are foundational to the successful installation of stone veneer, acting as the crucial link between the veneer and the structure. By understanding their importance, recognizing the types available, and adhering to best practices, builders and contractors can ensure that stone veneer not only enhances the aesthetic appeal of any structure but also stands the test of time in both performance and safety.

share:

-

The Ultimate Solution for Display Needs: Wire Grid PanelsNewsMay.06,2025

-

The Ultimate Guide to Galvanized Steel WireNewsMay.06,2025

-

Iron Binding Wire: The Ideal Solution for Your NeedsNewsMay.06,2025

-

Explore the Strength and Versatility of Galvanized Welded Wire FabricNewsMay.06,2025

-

Discover the Durability and Versatility of PVC Galvanized WireNewsMay.06,2025

-

Discover Quality China Stainless Steel Wire MeshNewsMay.06,2025

-

Understanding Wall Ties: Types and ImportanceNewsApr.28,2025