- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

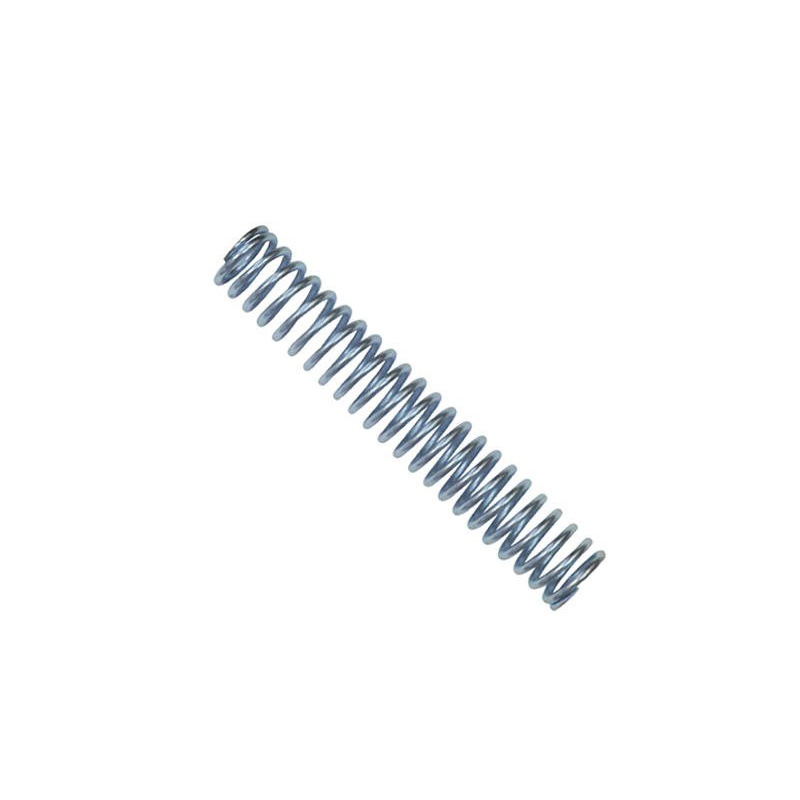

long tension spring

Understanding Long Tension Springs An Essential Component in Mechanical Engineering

Long tension springs play a pivotal role in various mechanical systems, providing essential force and support in applications ranging from household items to industrial machinery. These springs are designed to stretch and absorb energy, making them integral to the functioning of numerous devices.

A long tension spring is characterized by its ability to withstand tensile forces, meaning it is engineered to elongate when a load is applied. Typically made from high-carbon steel or stainless steel, these springs are coiled with precision to ensure optimal performance. The coil diameter, wire diameter, and spring length are critical design factors, influencing how much force the spring can exert and its overall durability.

One of the primary uses of long tension springs is in the automotive industry. They are often found in retractable seat belts, providing the necessary tension to ensure safety while driving. When the belt is pulled, the spring stretches, allowing the belt to extend smoothly and retract securely when not in use. This functionality highlights the importance of tension springs in enhancing passenger safety.

long tension spring

In addition to automotive applications, long tension springs are extensively used in various consumer products

. For instance, they can be found in devices like screen doors, where they assist in providing a seamless closure. Similarly, in the realm of outdoor equipment, tension springs are utilized in lawnmowers and garden tools, helping to maintain tension and balance during operation.Moreover, long tension springs are critical in industrial machinery. They are used in assembly lines, where they help manage and control movement, ensuring that components are held in place or move under specific conditions. This makes them invaluable in manufacturing processes that require precision and reliability.

When selecting a long tension spring for a particular application, engineers must consider the spring's load capacity, material properties, and environmental conditions. Factors like corrosion resistance and temperature tolerance are crucial, especially in industries that operate in harsh environments.

In conclusion, long tension springs are fundamental components in a wide array of applications. Their ability to absorb and exert force makes them indispensable in engineering and manufacturing. As technology continues to advance, the design and application of these springs are likely to evolve, enabling even greater efficiencies and innovations in mechanical systems. Whether in everyday tools or complex machinery, the significance of long tension springs cannot be overstated.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025