- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Exploring the Benefits and Applications of Long Length Extension Springs in Engineering

Understanding Long Length Extension Springs Applications, Types, and Benefits

Extension springs are a critical component in various mechanical systems, providing essential tension and flexibility. Among the different types of extension springs, long length extension springs play a unique role in applications that require extended reach, adaptability, and durability. This article explores the designs, applications, and benefits of long length extension springs, highlighting why they are indispensable in modern engineering.

What are Long Length Extension Springs?

Long length extension springs are designed to stretch and exert a pulling force. Unlike standard extension springs, which may have limited elongation capabilities, long length springs are manufactured to withstand significant extension while maintaining their structural integrity. These springs feature coiled wire that is typically made of high-quality materials such as stainless steel, music wire, or oil-tempered steel. The longer the spring, the more elastic potential it has, allowing for greater flexibility in engineering applications.

Types of Long Length Extension Springs

Long length extension springs can be classified based on various factors

1. Material Type The choice of material affects the spring's performance, durability, and resistance to environmental factors. Stainless steel springs are corrosion-resistant, making them ideal for outdoor applications, while high-carbon steel springs offer greater tensile strength.

2. Coiling Design Springs can have different coil designs, including round coils, square coils, or custom-shaped coils based on specific application requirements. The coil shape impacts the spring's flexibility and load-bearing capacity.

3. End Fittings Long length extension springs can be customized with various types of end fittings, such as hooks, loops, or eyes, which facilitate easy attachment to other components in machinery or mechanisms.

4. Force Rating Different applications may require springs with specific force ratings. It is crucial to select long length extension springs designed to handle the intended load without risk of failure.

Applications of Long Length Extension Springs

Long length extension springs are utilized in an array of industries and applications, including

- Automotive Sector They are commonly used in automotive components, such as hoods and trunks, providing the necessary tension for mechanisms like latch assemblies and shock absorbers.

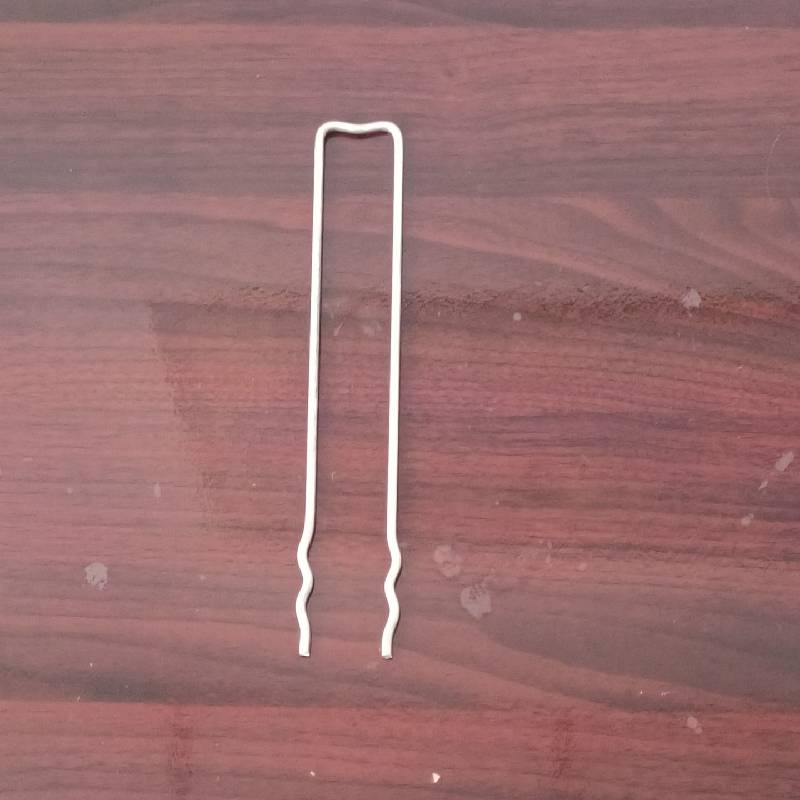

long length extension springs

- Industrial Machinery In manufacturing settings, these springs are integral to conveyor systems, providing tension in belts and other moving parts

.- Furniture and Seating Long length extension springs are utilized in folding chairs, sofas, and other furniture that requires reliable functionality with a smooth operation.

- Electronics In devices such as printers and scanners, long length extension springs assist in moving components precisely and reliably.

- Exercise Equipment They provide the necessary resistance and stability in various workout machinery, such as resistance bands and weight machines.

Benefits of Using Long Length Extension Springs

1. Versatility The adaptability of long length extension springs allows them to be used in diverse applications, making them suitable for multiple industries.

2. Space Efficiency Their extended length provides opportunities for better design in compact spaces, allowing for effective tensioning without the need for bulky mechanisms.

3. Durability High-quality materials and designs ensure that these springs can withstand demanding environments and heavy usage, reducing the frequency of replacements.

4. Customizability Manufacturers offer customization options for long length extension springs, enabling engineers to specify dimensions, materials, and designs that meet specific needs.

5. Cost-Effectiveness By ensuring reliable performance, long length extension springs can contribute to lower maintenance costs and improved machinery efficiency.

Conclusion

Long length extension springs are essential components in many mechanical systems, providing necessary tension and flexibility in various applications. Their versatility, durability, and customizability make them invaluable in industries ranging from automotive to manufacturing and beyond. By understanding the characteristics and applications of long length extension springs, engineers and designers can make informed decisions that enhance the performance and reliability of their products. Whether in critical machinery or everyday items, these springs are a testament to the importance of thoughtful engineering in creating efficient and effective solutions.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025