- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

light duty compression springs

Understanding Light Duty Compression Springs

Light duty compression springs play a crucial role in various mechanical applications, providing necessary force and support in countless devices. These springs are designed to compress under load, allowing them to absorb energy while offering resilience and flexibility. This article explores the characteristics, applications, and advantages of light duty compression springs.

Compression springs are characterized by their helical shape and are typically made from high-carbon steel, stainless steel, or other resilient materials. Light duty variants are generally smaller in size and wire diameter, designed to handle lower loads compared to heavy-duty springs. Despite their lighter construction, they are engineered to maintain durability and performance, making them suitable for an array of applications.

One of the most common uses of light duty compression springs is in consumer products. From pens and toys to electrical devices and automotive components, these springs are essential for enabling functions such as returning a mechanism to its original position or providing resistance during operation. For instance, they are often found in keyboard mechanisms, where they help provide the tactile feedback users expect.

light duty compression springs

In addition to consumer goods, light duty compression springs are pivotal in industrial applications

. They are frequently utilized in machinery, where they assist in maintaining the stability of moving parts and contribute to overall operational efficiency. These springs also serve in medical devices, ensuring precise and reliable performance in equipment like infusion pumps and diagnostic tools.The design and manufacturing of light duty compression springs involve careful consideration of various factors such as load requirements, dimensional constraints, and material properties. Engineers often use advanced software to simulate performance under different conditions, ensuring that the springs meet the specific requirements of their intended application.

One of the significant advantages of light duty compression springs lies in their versatility. They can be customized in terms of size, shape, and material, allowing for tailored solutions across diverse industries. Additionally, their relatively low cost, combined with effective performance, makes them an economical choice for manufacturers.

In conclusion, light duty compression springs are vital components in both everyday products and complex machinery. Their ability to provide reliable force and support plays a significant role in the functionality of various applications. As technology advances, the innovation in spring design and manufacturing continues to enhance their effectiveness, ensuring they remain indispensable in modern engineering and design.

share:

-

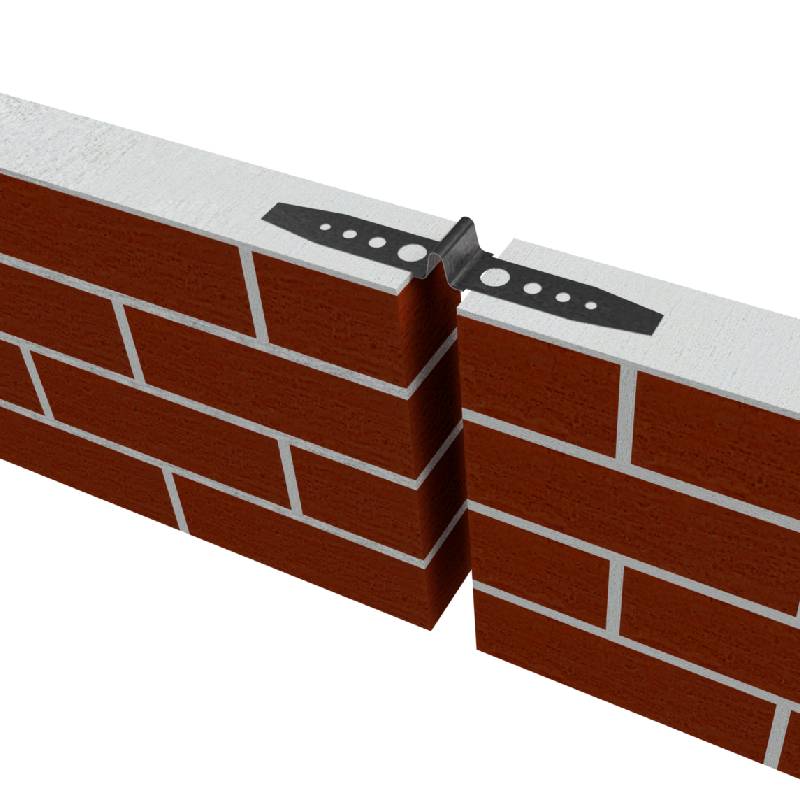

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025